Superfine WC-Co cemented carbide containing rare-earth elements and preparation method thereof

A technology of cemented carbide and rare earth elements, applied in the field of ultra-fine grain WC-Co cemented carbide and its preparation, to achieve the effects of simple and easy addition, low production cost, easy implementation and production application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

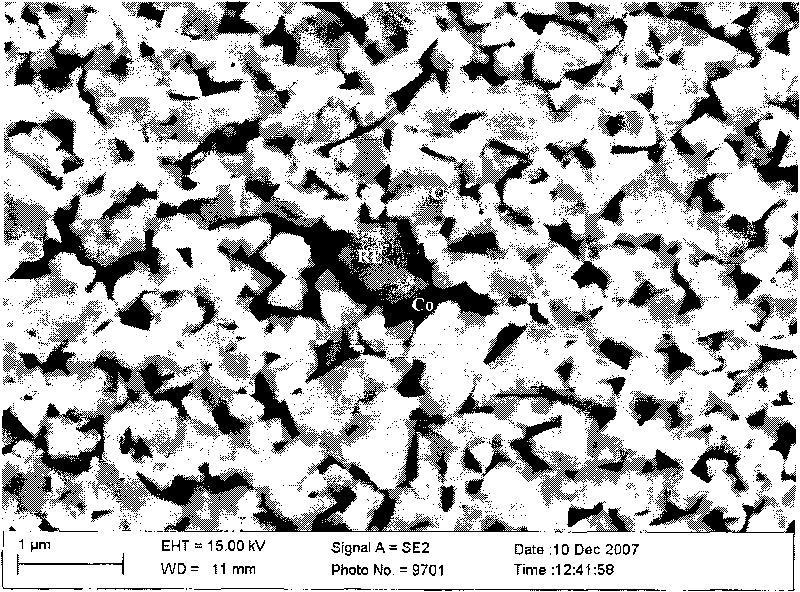

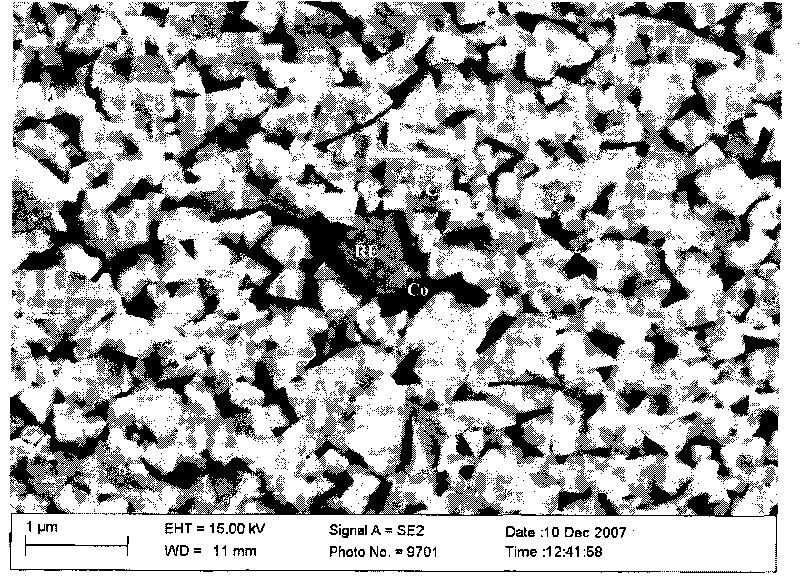

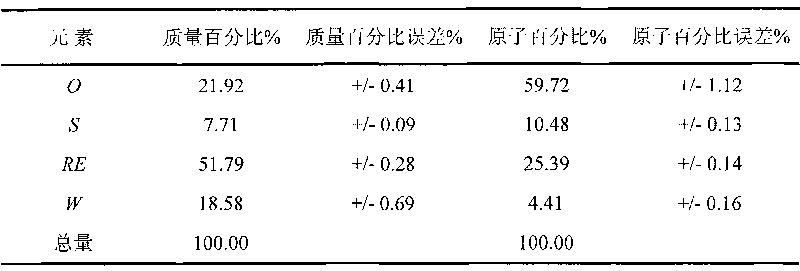

Image

Examples

Embodiment 1

[0025] Ultrafine grain WC-Co cemented carbide containing rare earth elements, the cemented carbide components are: WC hard phase (grain size is 0.25μm), Co binder phase, rare earth additive Y 2 o 3 (Y 2 o 3 particle size 80nm, purity ≥ 99.9%) and grain growth inhibitor Cr 3 C 2 , the weight of the WC hard phase accounts for 86.82% of the cemented carbide, the weight of the Co binder phase accounts for 12% of the cemented carbide, and the grain growth inhibitor Cr 3 C 2 The weight accounts for 1.0% of the cemented carbide, the rare earth additive Y 2 o 3 The weight accounts for 0.18% of the cemented carbide (Y 2 o 3 The weight of Y accounts for 1.18% of the Co binder phase).

[0026] A preparation method for ultrafine-grained WC-Co cemented carbide containing rare earth elements, the method steps are,

[0027] (1) weighing various powder raw materials by weight percentage;

[0028] (2) Put the prepared powder raw materials into a WC-Co cemented carbide tank, use WC-C...

Embodiment 2

[0035] Ultrafine grain WC-Co cemented carbide containing rare earth elements, the cemented carbide components are: WC hard phase (grain size is 0.25μm), Co binder phase, rare earth additive CeO 2 (CeO 2 particle size 50nm, purity ≥ 99.9%) and grain growth inhibitor Cr 3 C 2 , the weight of the WC hard phase accounts for 93.57% of the cemented carbide, the weight of the Co binder phase accounts for 6% of the cemented carbide, and the grain growth inhibitor Cr 3 C 2 The weight accounts for 0.4% of the cemented carbide, the rare earth additive CeO2 The weight accounts for 0.03% of the cemented carbide (CeO 2 The weight of Ce accounts for 0.4% of the Co binder phase).

[0036] A preparation method for ultrafine-grained WC-Co cemented carbide containing rare earth elements, the method steps are,

[0037] (1) weighing various powder raw materials by weight percentage;

[0038] (2) Put the prepared powder raw materials into a WC-Co cemented carbide tank, use WC-Co cemented carb...

Embodiment 3

[0045] Ultrafine-grained WC-Co cemented carbide containing rare earth elements, the cemented carbide components are: WC hard phase (grain size is 0.22 μm), Co binder phase, La 2 o 3 and Sm 2 o 3 The mixed rare earth oxide of composition (the particle size of mixed rare earth oxide is 37nm, purity ≥ 99.9%, mass ratio La 2 o 3 :Sm 2 o 3 =1:1) and grain growth inhibitor VC, the weight of WC hard phase accounts for 89.18% of cemented carbide, the weight of Co binder phase accounts for 10% of cemented carbide, and the weight of grain growth inhibitor VC accounts for 0.7% of cemented carbide, the weight of mixed rare earth oxides accounts for 0.12% of cemented carbide (La 2 o 3 and Sm 2 o 3 The sum of the weights of La and Sm in the composition of the mixed rare earth oxide accounts for 1.03% of the Co binder phase).

[0046] A preparation method for ultrafine-grained WC-Co cemented carbide containing rare earth elements, the method steps are,

[0047] (1) weighing variou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com