Downhole self-priming particle jet drilling device based on Venturi effect

A Venturi effect, self-priming technology, applied in liquid/gas jet drilling, drilling equipment, drill bits, etc., can solve the problems of high drilling cost, short service life of drilling tools, slow drilling speed, etc., and achieve enhanced start-up and Effects of purification, increased ROP, and low manufacturing and use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

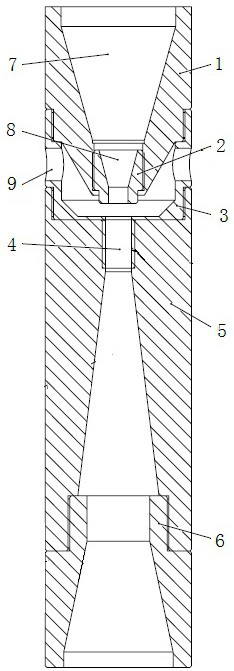

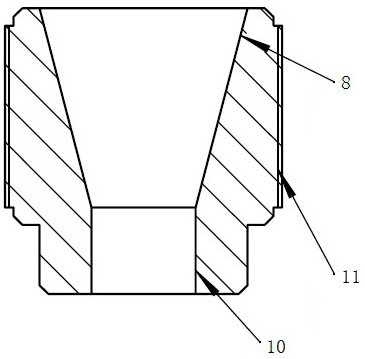

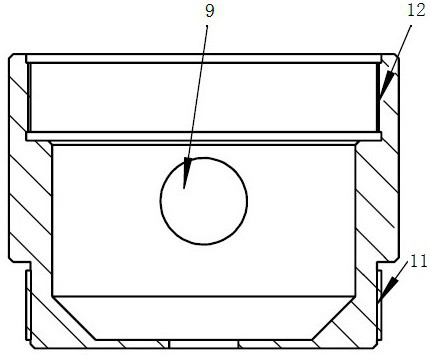

[0021] Below in conjunction with accompanying drawing, the present invention will be further described:

[0022] combine figure 1 , figure 2 , image 3 , Figure 4 As shown, this downhole self-priming particle jet drilling device based on the Venturi effect includes an upper joint 1, a nozzle 2, a liquid inlet chamber 3, a throat pipe 4, a diffuser pipe 5, and a lower joint 6. The upper end of the liquid inlet chamber 3 has an inner Thread 12, threaded with the upper joint 1, the inner cavity of the upper joint 1 is composed of the horn section 7 and the nozzle section, the outer part of the corresponding upper joint of the nozzle section is a reduced diameter section, the nozzle section is an equal diameter section, and the nozzle 2 is threaded with the nozzle section , the nozzle 2 and the nozzle section extend into the liquid inlet chamber 3, and the flow rate of the inflowing liquid can be changed by adjusting the size of the nozzle 2; the liquid inlet chamber 3 has tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com