Shadow mask type plasma display board

A plasma and display panel technology, applied in the direction of solid cathode parts, cold cathode tubes, etc., to achieve the effect of improving luminous brightness and luminous efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

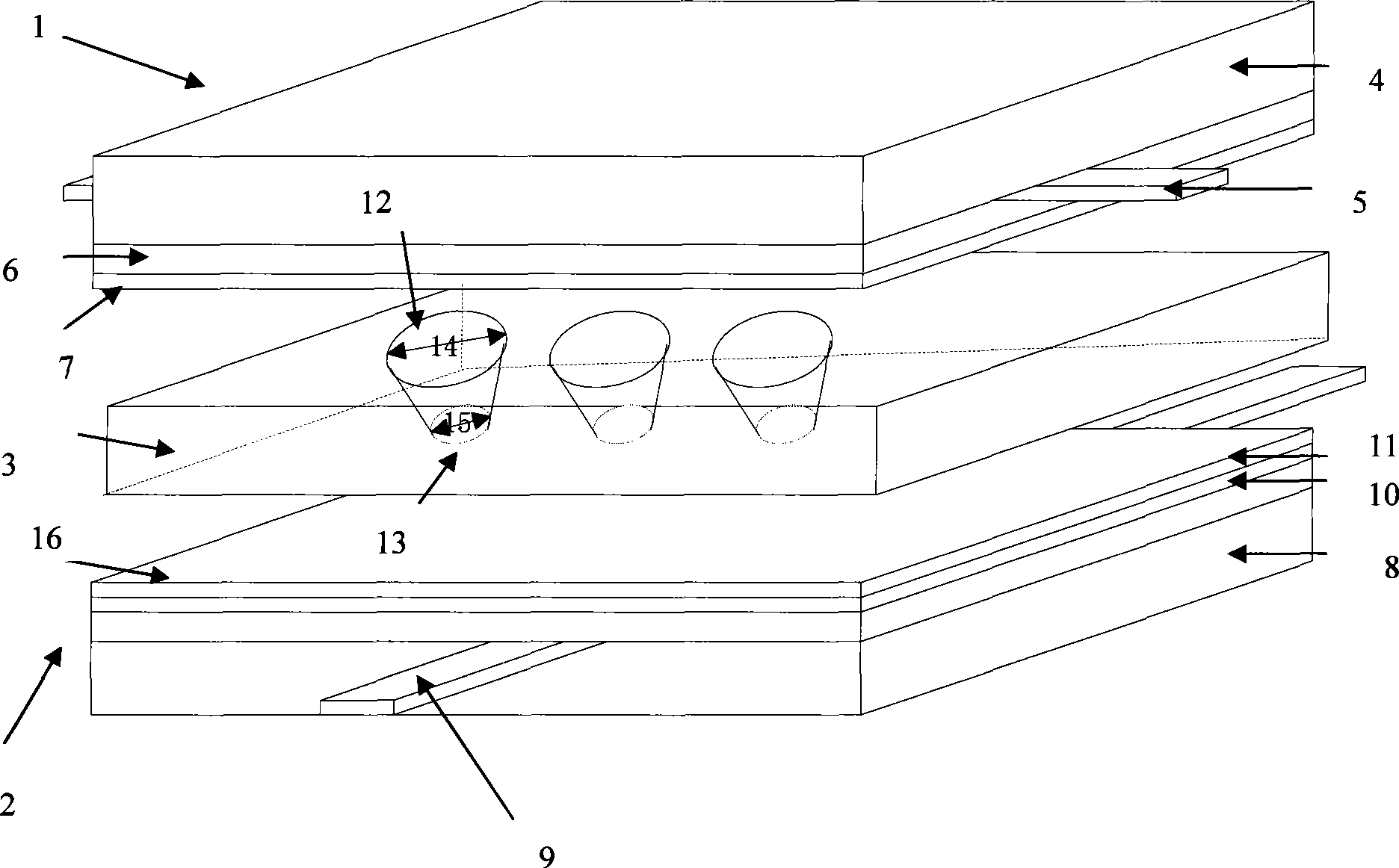

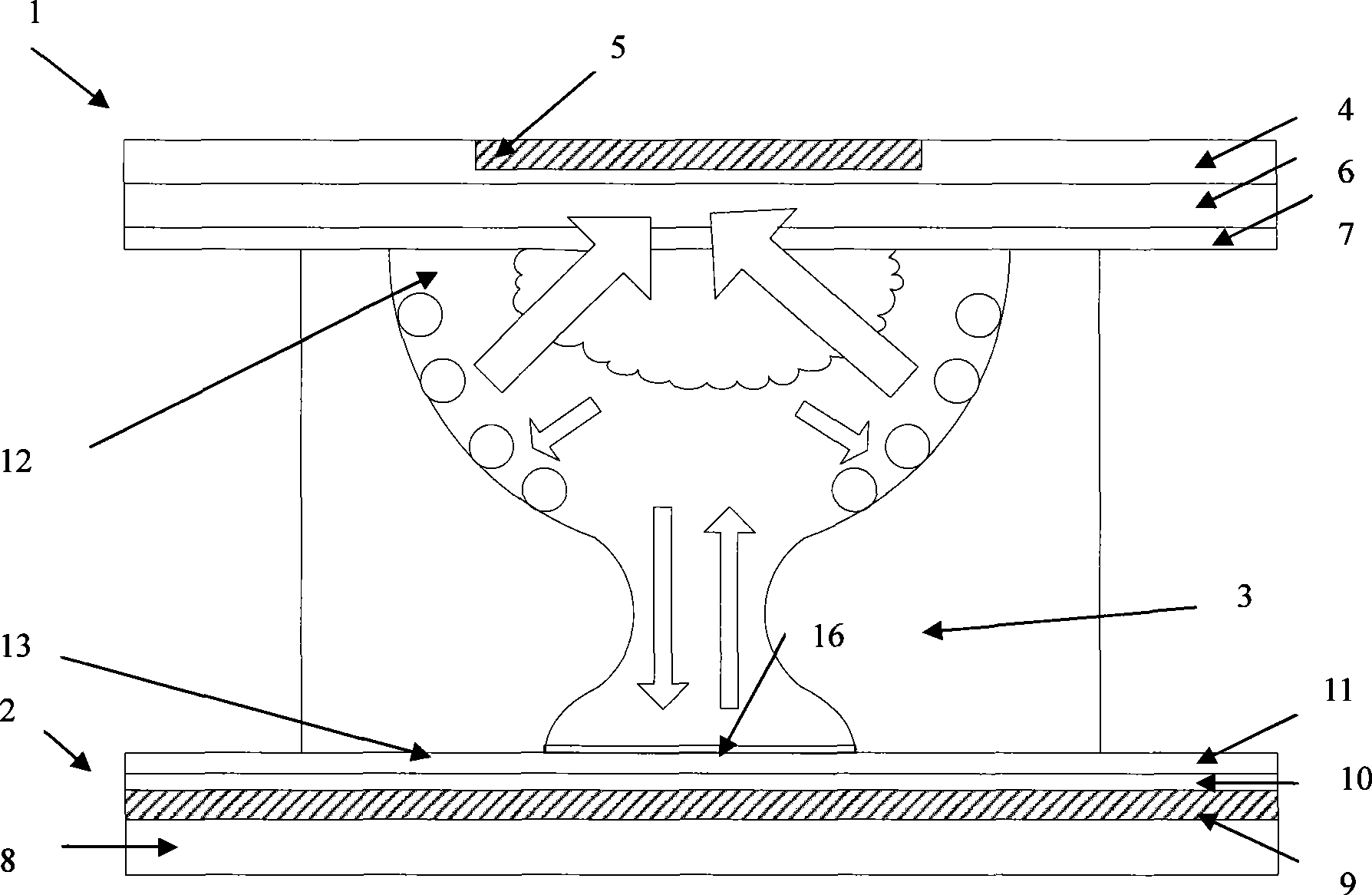

[0018] Such as Figure 1-4 shown

[0019] A shadow mask type plasma display panel, such as figure 1 As shown, it includes a front substrate 1, a rear substrate 2, and a shadow mask 3, wherein the shadow mask 3 is packaged between the front substrate 1 and the rear substrate 2, and the front substrate 1 includes a front substrate glass substrate 4, scanning electrodes 5, The front substrate dielectric layer 6, the front substrate protective film 7, and the scanning electrodes 5 are arranged in parallel on the front substrate glass substrate 4, the front substrate dielectric layer 6 covers the scanning electrodes 5, and the front substrate protective film 7 covers the front substrate dielectric layer 6 Above; the rear substrate 2 includes a rear substrate glass substrate 8, an address electrode 9, a rear substrate dielectric layer 10 and a rear substrate protective film 11, and the address electrode 9 is arranged in parallel on the rear substrate glass substrate 8, and the rear...

Embodiment 2

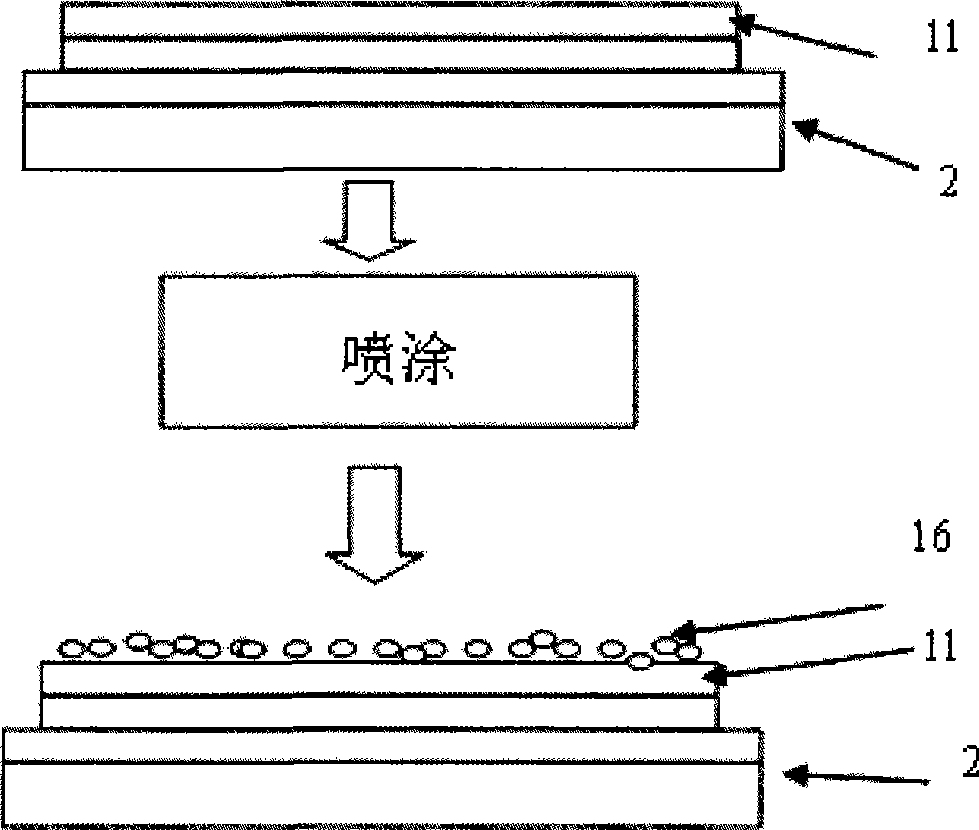

[0026] In the first embodiment above, the diffuse reflection film 16 can also be formed of SiO with a thickness of 50 nm to 1 μm by continuous vapor deposition while forming the film 11. 2 Reflective film. The working principle of the shadow mask type plasma display panel constructed in this embodiment is the same as that in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com