Dyeing method of polypropylene non-woven fabric material

A polypropylene non-woven fabric and dyeing method technology, which is applied in the dyeing field of polypropylene non-woven fabric materials, can solve the problems of high cost and incomplete chromatogram, and achieve the effect of fast and cheap operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Weigh 0.25g of disperse blue, disperse red and disperse yellow, add 7.5g of self-crosslinking adhesive, add water to make up the total mass to 50g, stir at 37°C for 10min at a high speed, and the speed is 300 rpm to make disperse dyes color paste;

[0024] (2) Immerse the polypropylene non-woven fabric in three kinds of disperse dye color pastes respectively, take it out after 5 minutes, the liquid retention rate is 100%, and place it in an oven for 5 minutes at 90°C;

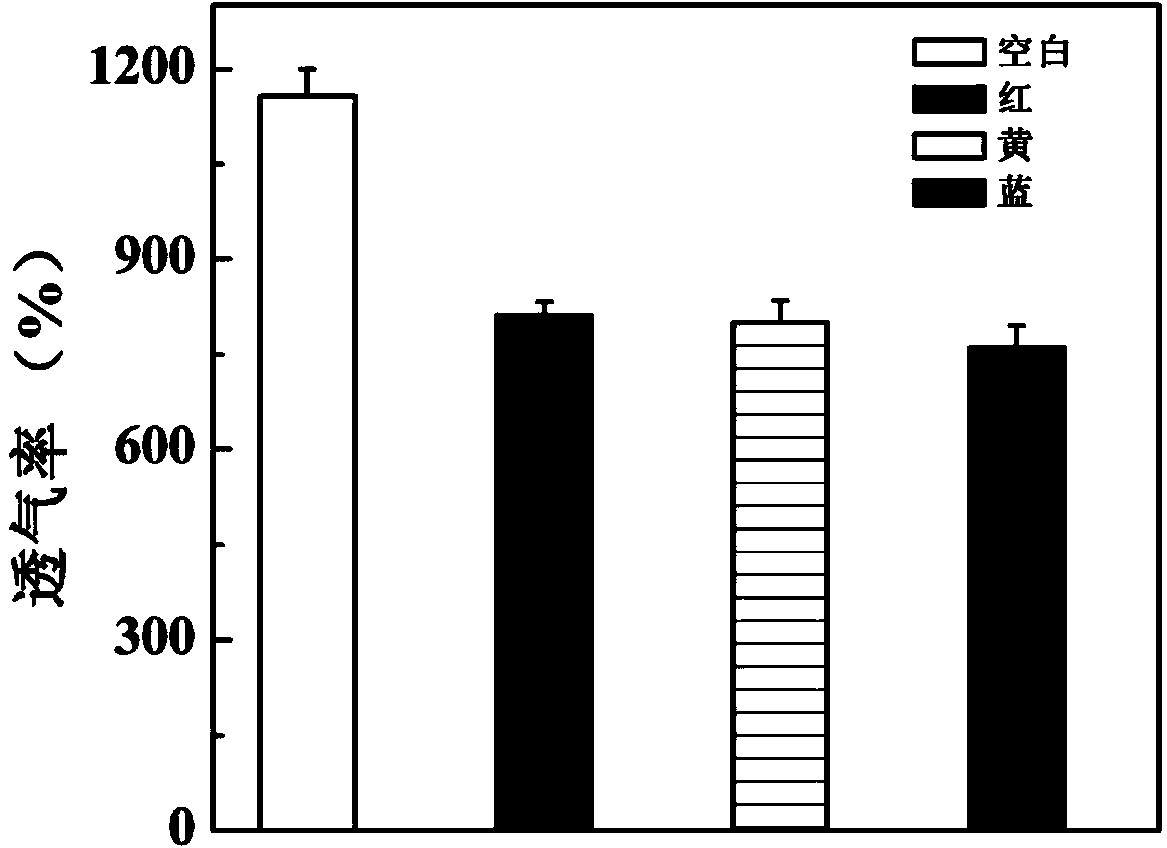

[0025] (3) Cut undyed non-woven fabrics and dyed non-woven fabrics into 200mm*200mm, and test their air permeability in a differential pressure air-permeable instrument;

[0026] (4) Test results such as figure 1 As shown, the polypropylene non-woven fabric has a high air permeability. After dyeing with paint, the surface of the polypropylene fiber is formed into a film, and its air permeability decreases, but the air permeability is still high.

Embodiment 2

[0028] (1) Weigh 0.125g of disperse blue, disperse red and disperse yellow, add 10g of self-crosslinking adhesive, add water to make up the total mass to 50g, stir at 37°C for 15min at a speed of 500 rpm to make disperse dye color pulp;

[0029] (2) Pad the polypropylene non-woven fabric in the three kinds of disperse dye color paste respectively, take it out after 5 minutes, control the liquid retention rate to 300%, pass it through the paddle car, and dry it in an oven at 90°C for 3 minutes;

[0030] (3) Cut the dyed non-woven fabric into 50mm*200mm, and test its dry rubbing fastness and wet rubbing fastness in the rubbing fastness meter;

[0031] (4) The test results are shown in Table 1. The polypropylene nonwoven fabric after finishing with disperse dye paste has a certain degree of rubbing resistance, and the dry rubbing fastness is higher than the wet rubbing fastness.

[0032] sample Dry rubbing fastness Wet rubbing fastness red 3 2 yellow 2...

Embodiment 3

[0035] (1) Weigh 0.75g of Disperse Blue, Disperse Red and Disperse Yellow, add 16g of self-crosslinking adhesive, add water to make up the total mass to 100g, stir at 37°C for 30min at a high speed, and the speed is 800 rpm to make a disperse dye color paste ;

[0036] (2) Immerse the polypropylene non-woven fabric in the three kinds of disperse dye color pastes respectively, take it out after 30s, the liquid-carrying rate is 300%, and place it in an oven for 4 minutes at 80°C;

[0037] (3) Cut the dyed non-woven fabric into 40mm*100mm, and fit it with the wool lining, and test its washing fastness in a soaping fastness tester;

[0038] (4) The test results are shown in Table 2. The polypropylene non-woven fabric after finishing with disperse dye paste has a certain degree of washing and rubbing resistance, and the number of fading is not high.

[0039] sample Washing fastness Color fastness red 3-4 3 yellow 2 2 blue 3 2

[0040] Table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com