Equipment for disassembling threaded part

A technology of threaded parts and equipment, which is applied in the field of projectile pressing powder processing, can solve the problems of affecting the automatic processing process, low processing efficiency, hidden safety hazards, etc., and achieve the effects of reducing labor intensity, increasing productivity, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

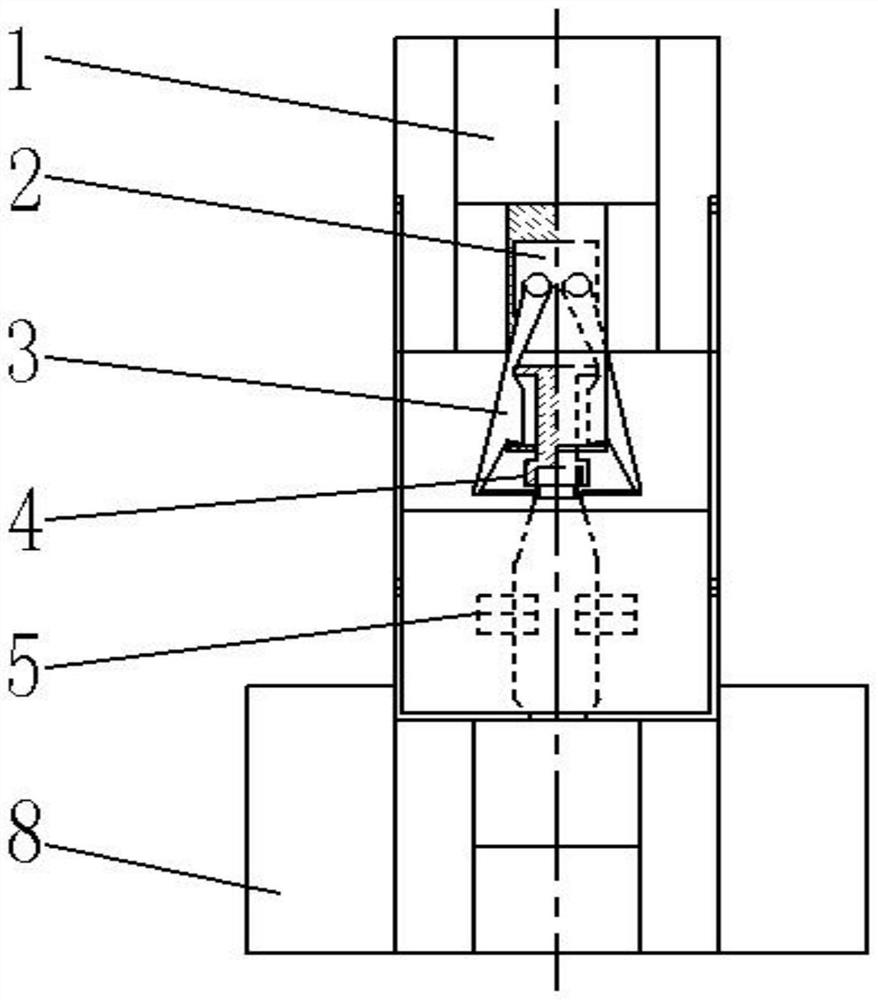

[0022] A device for the removal of threaded parts,

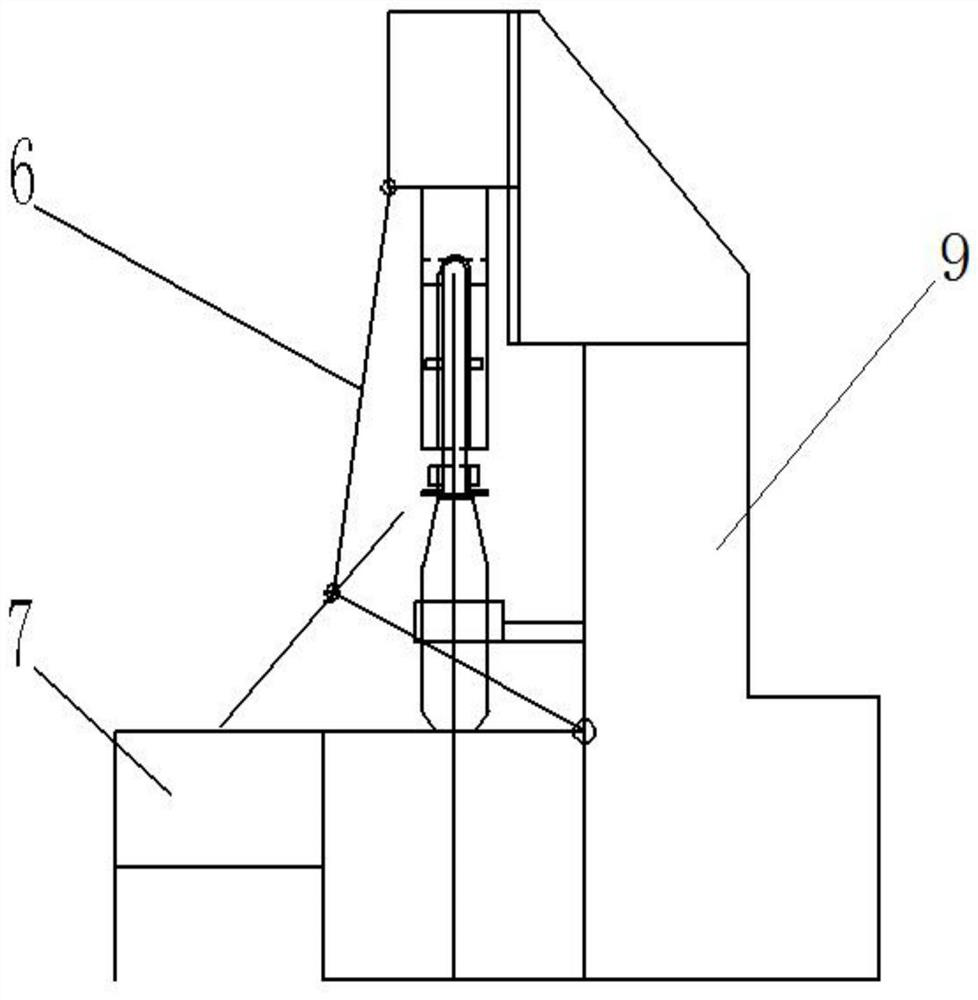

[0023] Screw removal equipment, including: movable platform and motor 1, main shaft 2, clamping mechanism 3, socket wrench 4, manipulator 5, collecting mechanism 6, collecting basket 7, machine base 8, and machine body 9.

[0024] There is a track on the upper part of the fuselage 9 of the equipment, and a movable platform 1 is installed on the track, and the movable platform 1 can move up and down along the track;

[0025] The motor 1 is fixedly installed above the movable platform. The motor is mounted upside down with the motor shaft protruding from under the platform.

[0026] The upper part of the main shaft 2 is connected on the shaft of the motor, and when the motor rotates, the main shaft 2 can rotate under the movable platform 1 .

[0027] There are 2 through holes perpendicular to the main shaft in the middle of the main shaft, and there are spline grooves on the inner side of the bottom of the main shaft 2. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com