Special compound enzyme preparation for sugar production and preparation method and application of special compound enzyme preparation

A composite enzyme preparation, dextranase technology, applied in the directions of biochemical equipment and methods, applications, glycosylase, etc., can solve the problems such as inability to effectively remove various components, little improvement in simplicity and purity, and defects in the effect of composite enzymes, Achieving effects that aid absorption and crystallization, reduce yield, and reduce viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

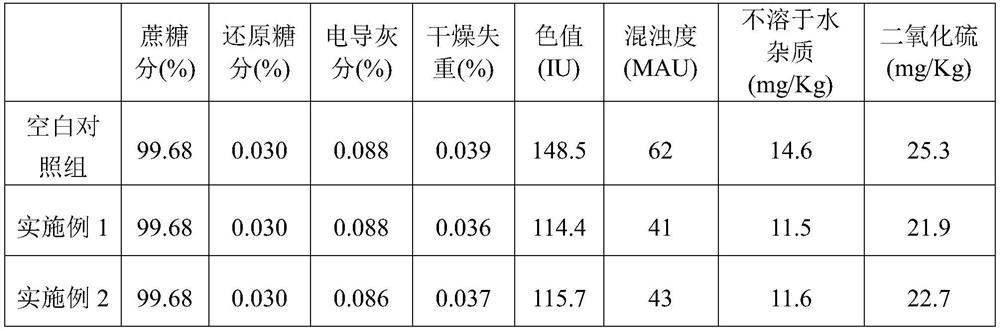

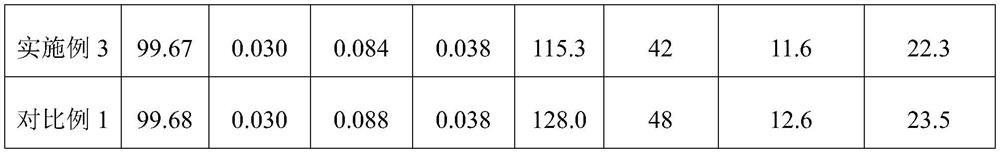

Embodiment 1

[0023] A special composite enzyme preparation for sugar clarification, which is composed of the following ingredients in weight percent: dextranase 45%, pectinase 20%, cellulase 10%, polyphenol oxidase 5%, papain 5%, magnesium chloride 10% , polydimethyldiallylammonium chloride 5%. Wherein, dextranase is made up of 70% endo-dextranase and 30% exo-dextranase by weight percentage; Pectinase is made up of 60% pectin lyase, 30% aldolase and 10% aldolase ; Cellulase is composed of 50% exocellulase, 40% endocellulase and 10% β-glucanase by weight percentage; polyphenol oxidase is composed of 60% laccase and 40% catechin by weight Composition of phenol oxidase.

[0024] A preparation method of a special compound enzyme preparation for sugar clarification, comprising the following steps: uniformly mixing raw material enzymes in proportion to obtain a premixed enzyme liquid; then dissolving magnesium chloride and polydimethyldiallylammonium chloride in The pre-mixed enzyme liquid is ...

Embodiment 2

[0026] A special composite enzyme preparation for sugar clarification, which is composed of the following ingredients in weight percent: dextranase 42%, pectinase 23%, cellulase 9%, polyphenol oxidase 6%, papain 6%, magnesium chloride 8% , polydimethyldiallylammonium chloride 6%. Wherein the composition of dextranase, pectinase, cellulase and polyphenol oxidase is the same as that of Example 1, and the preparation method is the same as that of Example 1.

Embodiment 3

[0028] A special composite enzyme preparation for sugar clarification, which is composed of the following components in weight percentage: dextranase 47%, pectinase 18%, cellulase 11%, polyphenol oxidase 5%, papain 4%, magnesium chloride 11% , polydimethyldiallylammonium chloride 4%. Wherein the composition of dextranase, pectinase, cellulase and polyphenol oxidase is the same as that of Example 1, and the preparation method is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com