Patents

Literature

39results about "Purification using microorganisms/enzymes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Enzyme method of extracting oils and proteins from vegetable matter in an aqueous medium

ActiveUS20120196332A1Volume of water is minimizedReduce sewagePeptide preparation methodsFermentationVegetable matterEmulsion

Method for extracting oils, proteins and fermentable sugars from vegetable material in an aqueous medium, includes:a) adding water to the vegetable material;b) adding an enzyme mixture containing at least one cellulase, at least one hemicellulase, and at least one pectinase, the ratio between the pectinase activity and the cellulase activity being at least 0.14, and the ratio between the pectinase activity and the hemicellulase activity being at least 7.10−3, the pectinase activity being less than 120 μmol / min / mL;c) incubating the vegetable material and the enzyme mixture with stirring to release oils, proteins and fermentable sugars in the reaction medium;d) separating the reaction medium to obtain free oil, an aqueous phase containing proteins and fermentable sugars, and a solid phase;e) optionally separating and recycling an emulsion of free oil or aqueous phase, to the medium;f) separating the proteins and fermentable sugars from the aqueous phase.

Owner:UNIVERSITY OF LORRAINE

Enzyme method of extracting oils and proteins from vegetable matter in an aqueous medium

ActiveUS8679794B2Volume of water is minimizedReduce sewagePeptide preparation methodsFermentationProteinExocellulase activity

Method for extracting oils, proteins and fermentable sugars from vegetable material in an aqueous medium, includes:a) adding water to the vegetable material;b) adding an enzyme mixture containing at least one cellulase, at least one hemicellulase, and at least one pectinase, the ratio between the pectinase activity and the cellulase activity being at least 0.14, and the ratio between the pectinase activity and the hemicellulase activity being at least 7.10−3, the pectinase activity being less than 120 μmol / min / mL;c) incubating the vegetable material and the enzyme mixture with stirring to release oils, proteins and fermentable sugars in the reaction medium;d) separating the reaction medium to obtain free oil, an aqueous phase containing proteins and fermentable sugars, and a solid phase;e) optionally separating and recycling an emulsion of free oil or aqueous phase, to the medium;f) separating the proteins and fermentable sugars from the aqueous phase.

Owner:UNIVERSITY OF LORRAINE

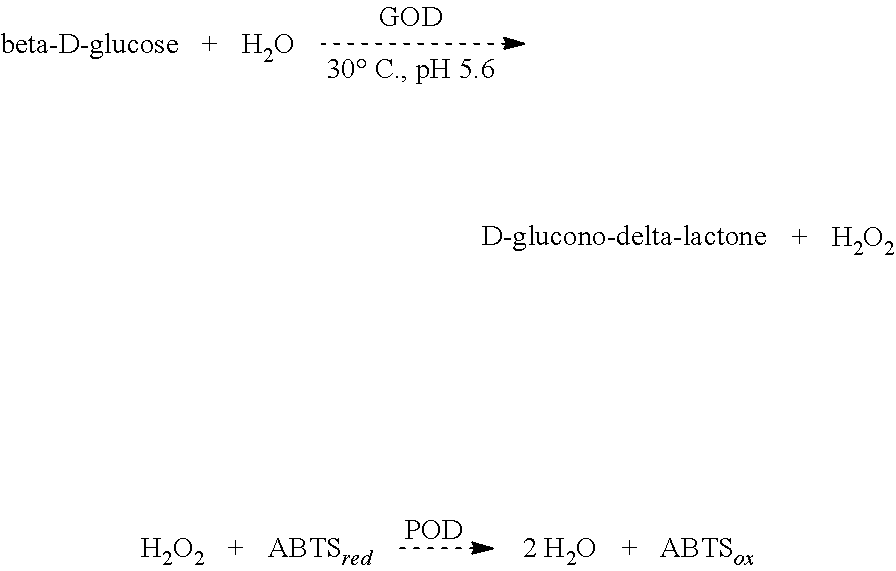

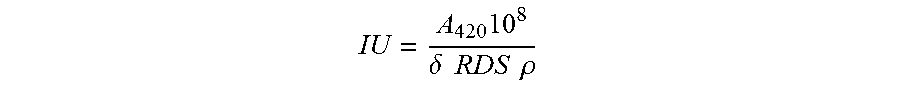

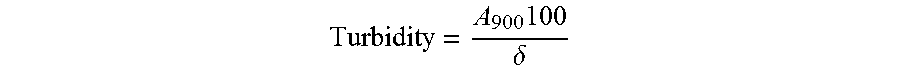

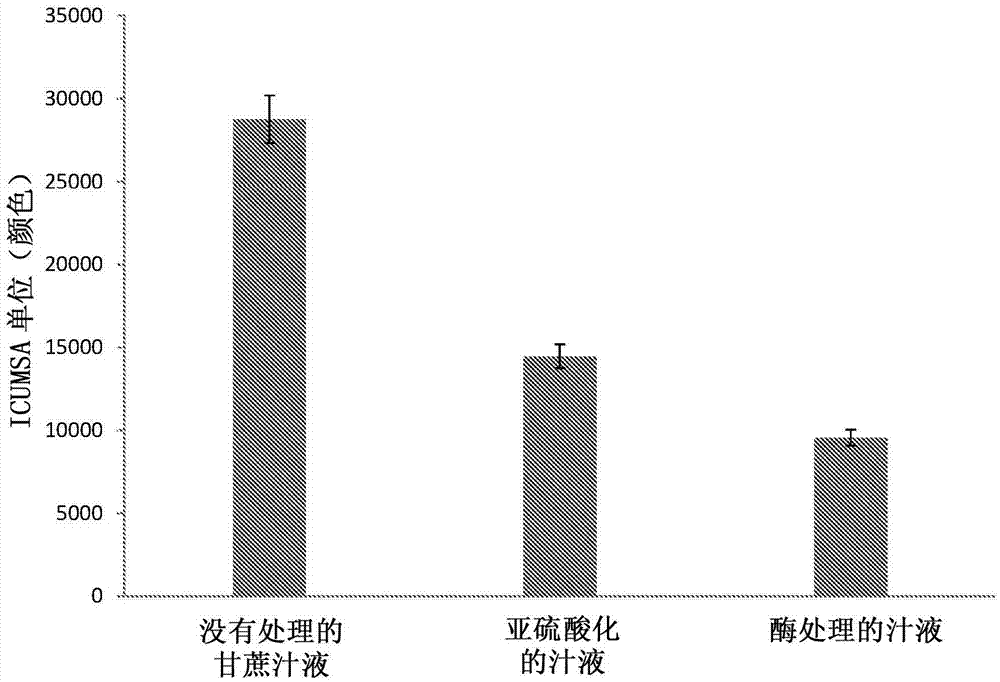

Method for decolorization of sugar solution using enzymes

InactiveUS20160249669A1Prevent color formationInhibition formationFood preparationPurification using microorganisms/enzymesFruit juiceFiltration

The present invention relates to methods for decolorizing a sugar solution obtained from sugar crops, wherein the solution is treated enzymatically with an oxidoreductase resulting in a decrease in color and / or turbidity of the solution. Also described are methods for decolorizing fruit juice solutions using oxidoreductases. Specifically, glucose oxidase, carbohydrate oxidases, glucose dehydrogenase, cellobiose dehydrogenase and glucooligosaccharide oxidase are described. At least action of glucose oxidase results in the formation of a coloured precipitate, which may be removed by filtration or centrifugation.

Owner:NOVOZYMES AS

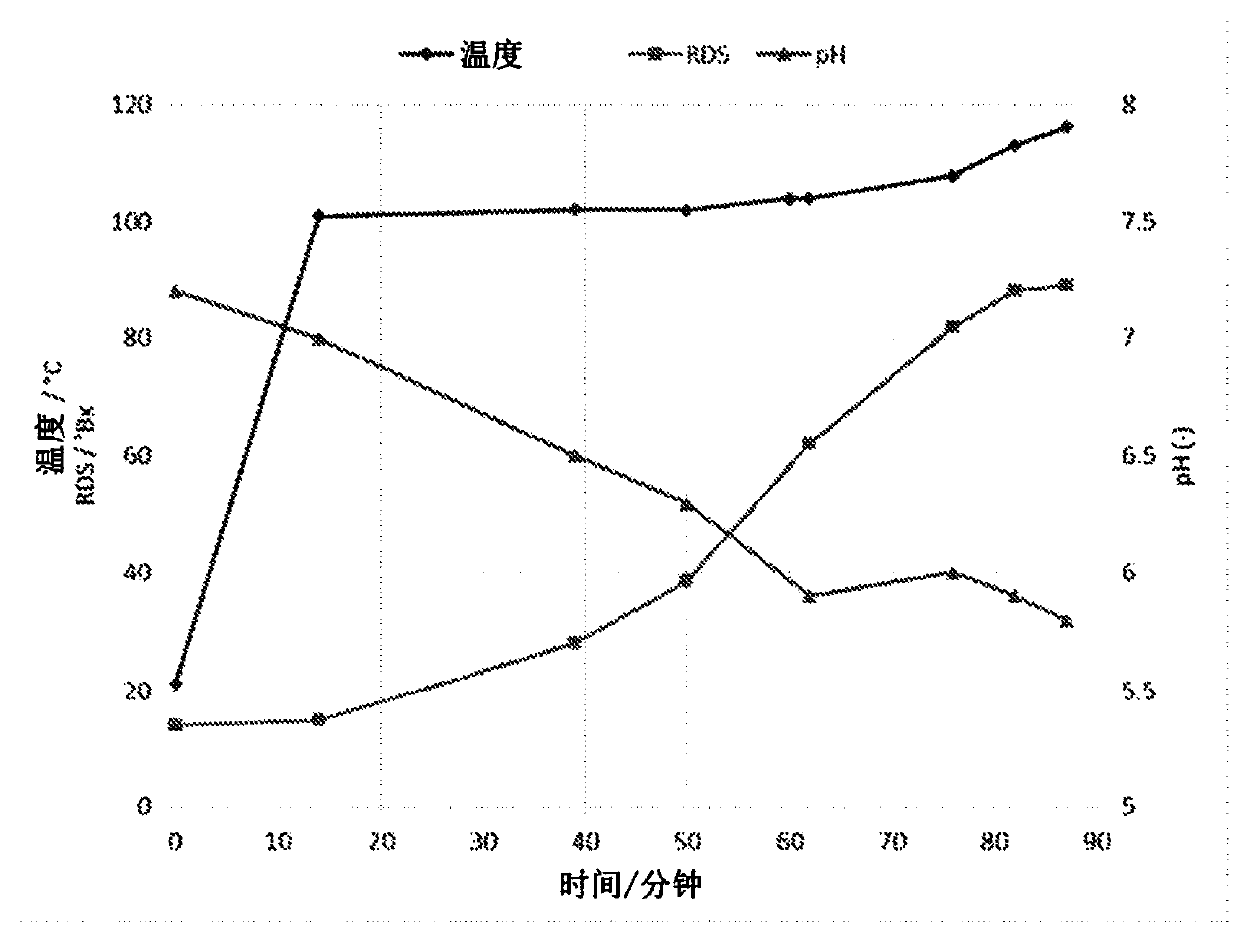

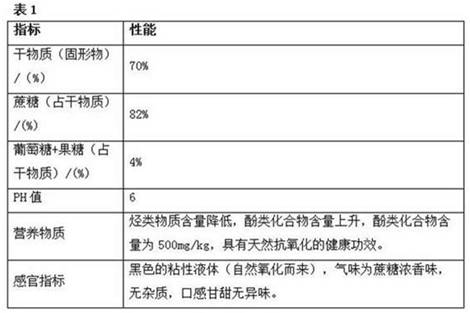

Method for preparing black sugar

InactiveCN105861761ANo secondary pollution will occurHigh medicinal valueSugar productsPurification by physical meansProduct inspectionEnzymatic hydrolysis

The present invention belongs to the field of food processing, and particularly relates to a method for preparing black sugar. The method comprises the steps of pre-treating sugarcane, cleaning the sugarcane, peeling the sugarcane, squeezing the sugarcane into juice, heating the juice to sterilize the juice, filtering the juice, concentrating the juice, subjecting the juice to enzymatic hydrolysis reaction, concentrating the juice for a second time, conducting the thermal reaction, subjecting an obtained product to dehumidification reaction, packing the finished product and the like. According to the technical scheme of the method for preparing black sugar, firstly, the squeezing and concentrating operation is conducted, and then the enzymatic hydrolysis reaction is conducted. After that, the concentrating and heating operation is conducted to obtain black sugar. In this way, the drying and the crystallizing are not required, and a standard purification plant is established. The secondary pollution of the obtained product is avoided, so that the finished product is cleaner. Each step is conducted according to a strict process flow for production, incoming inspection, production inspection and finished product inspection, so that the product is safer. The majority of nutrient substances in the sugarcane is maintained, and the black sugar is higher in medicinal value.

Owner:刘伟亚

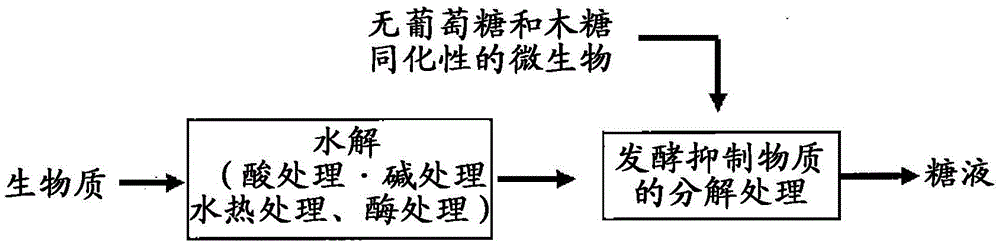

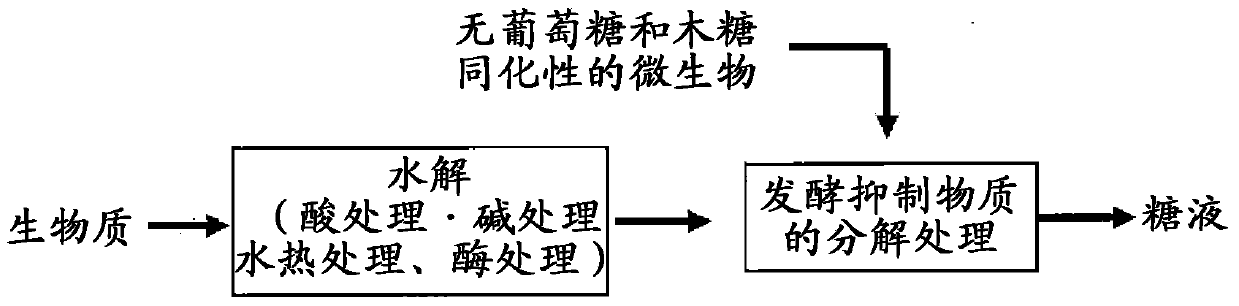

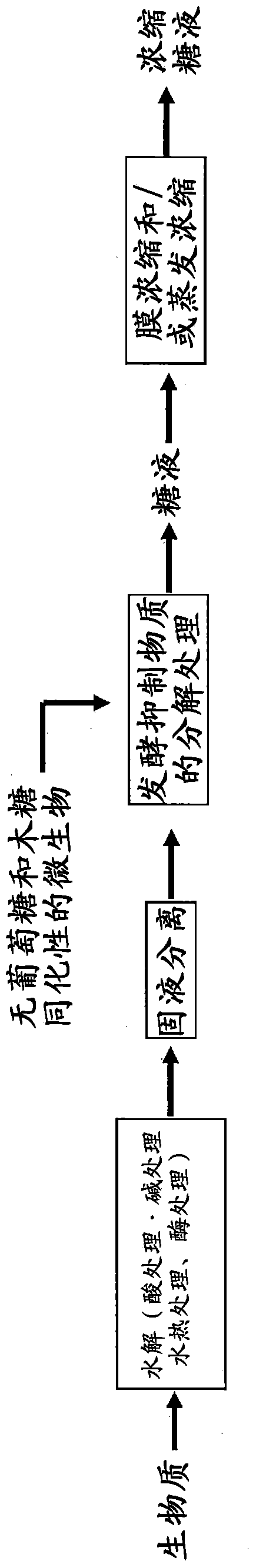

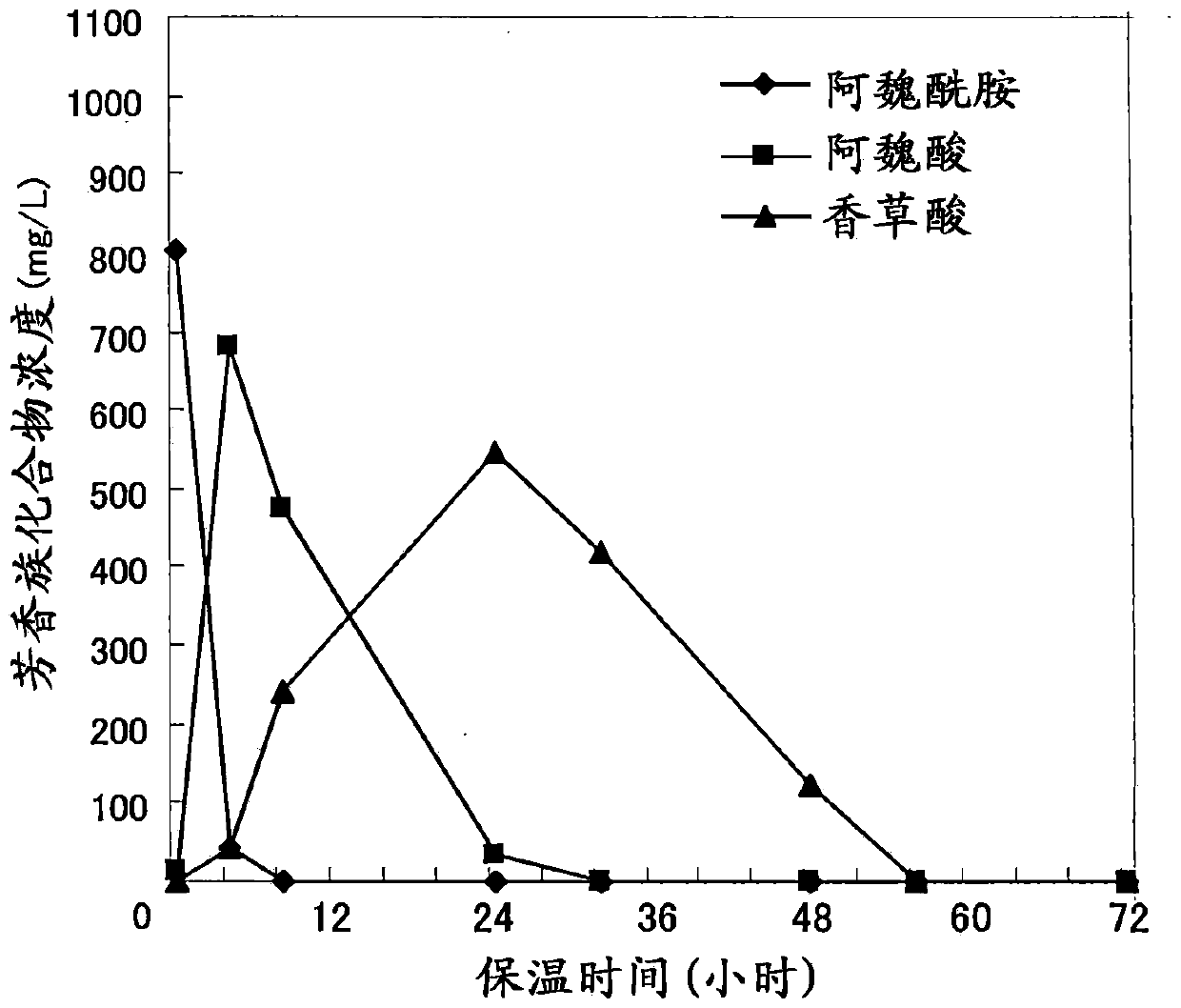

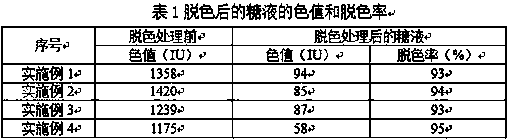

Method for producing saccharide solution

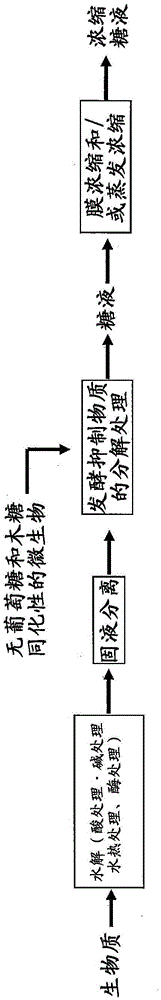

[Problem] An aqueous saccharide solution obtained from biomass contains various fermentation-inhibiting substances, however, it is possible to easily remove fermentation-inhibiting substances derived from biomass at a low cost by treating the aqueous saccharide solution with microbes that do not utilize glucose or xylose or with a crude enzyme product derived from said microbes.

Owner:TORAY IND INC

Processes and apparatus for refining sugarcane to produce sugars, biofuels, and/or biochemicals

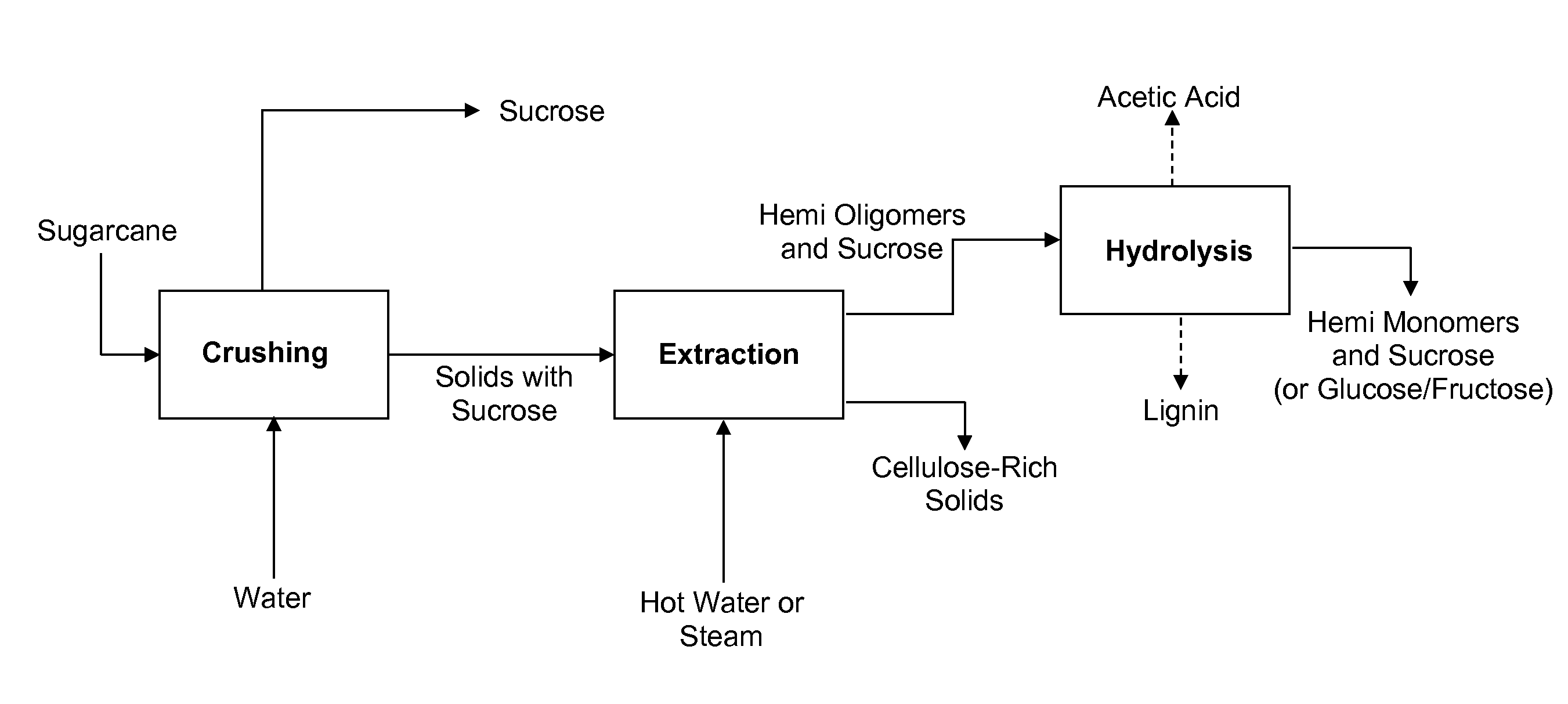

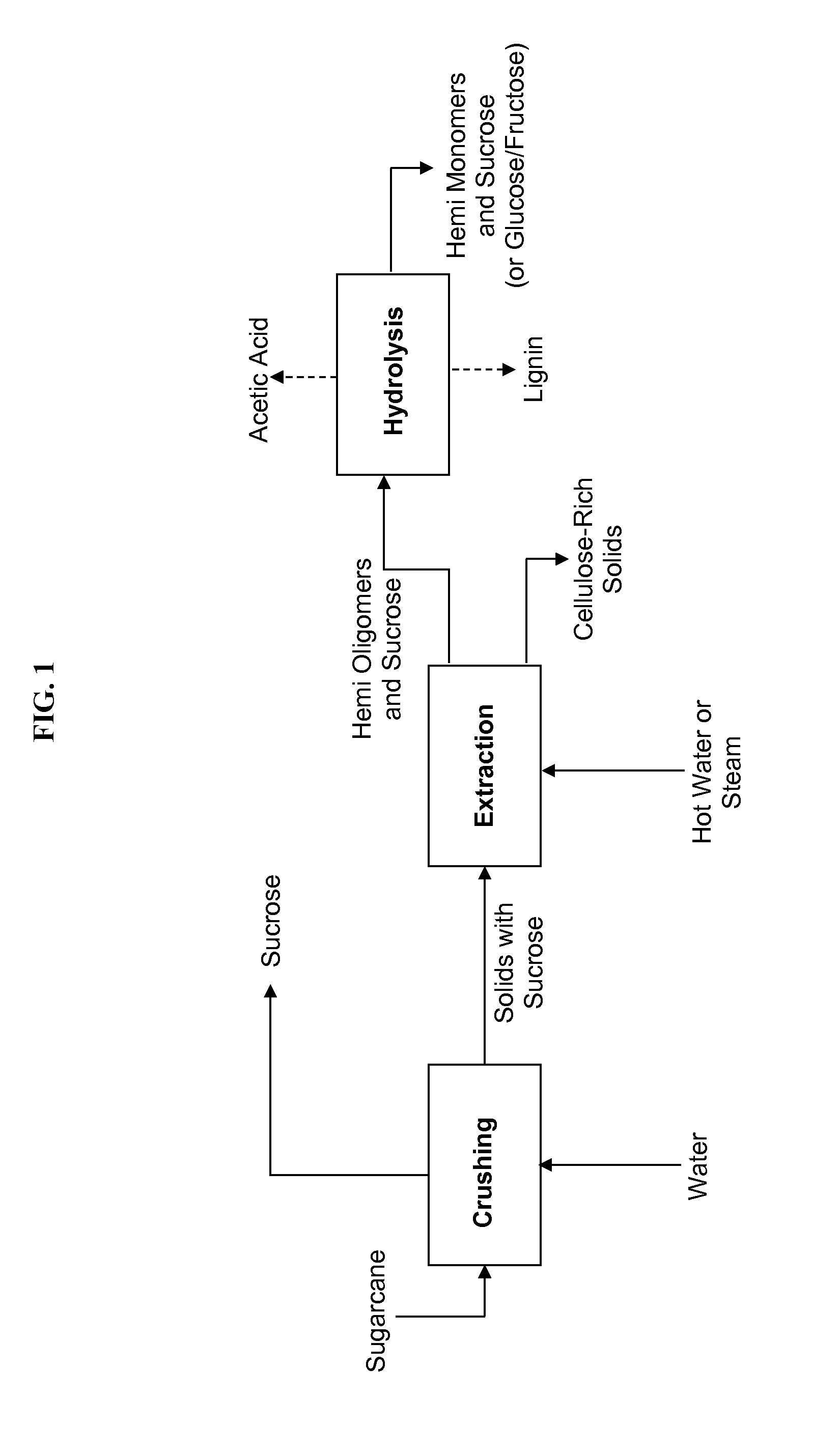

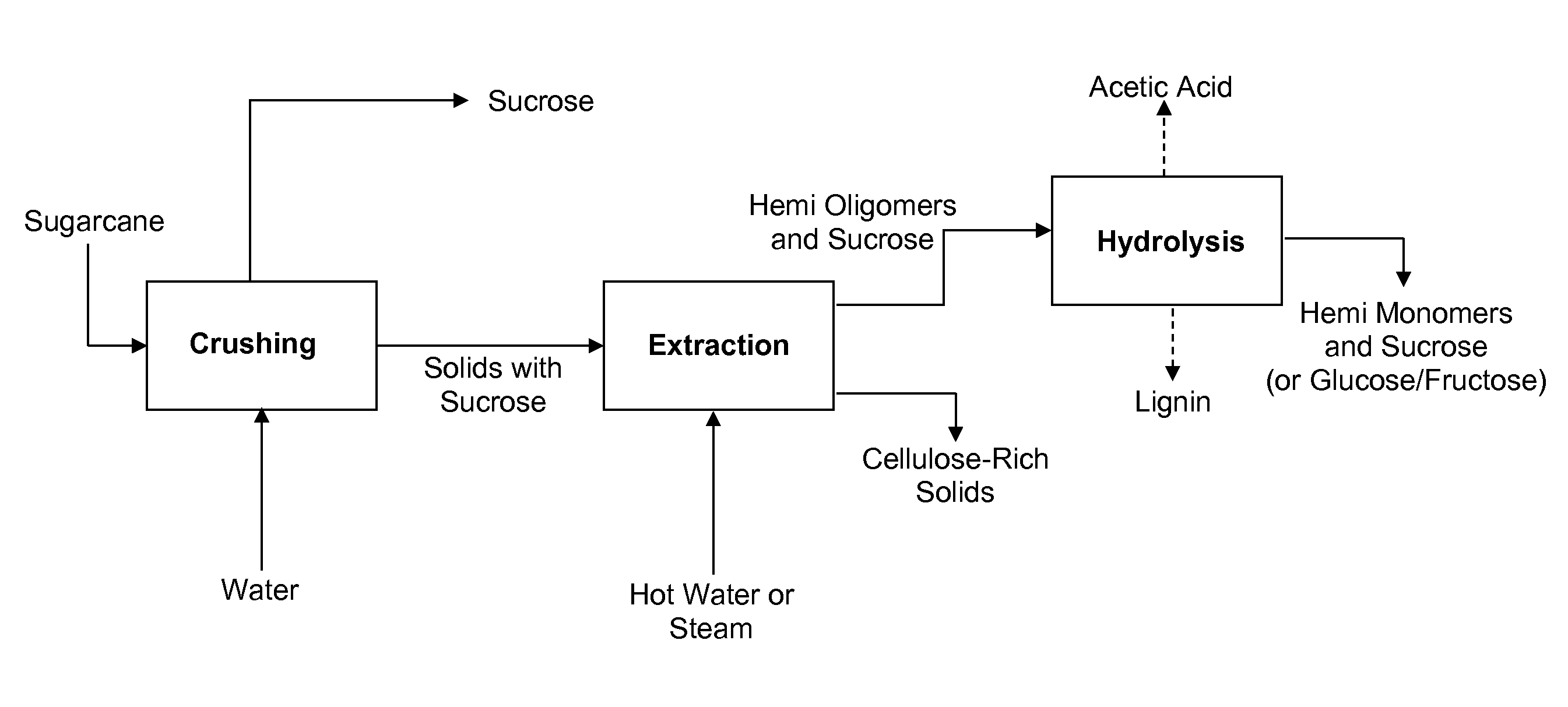

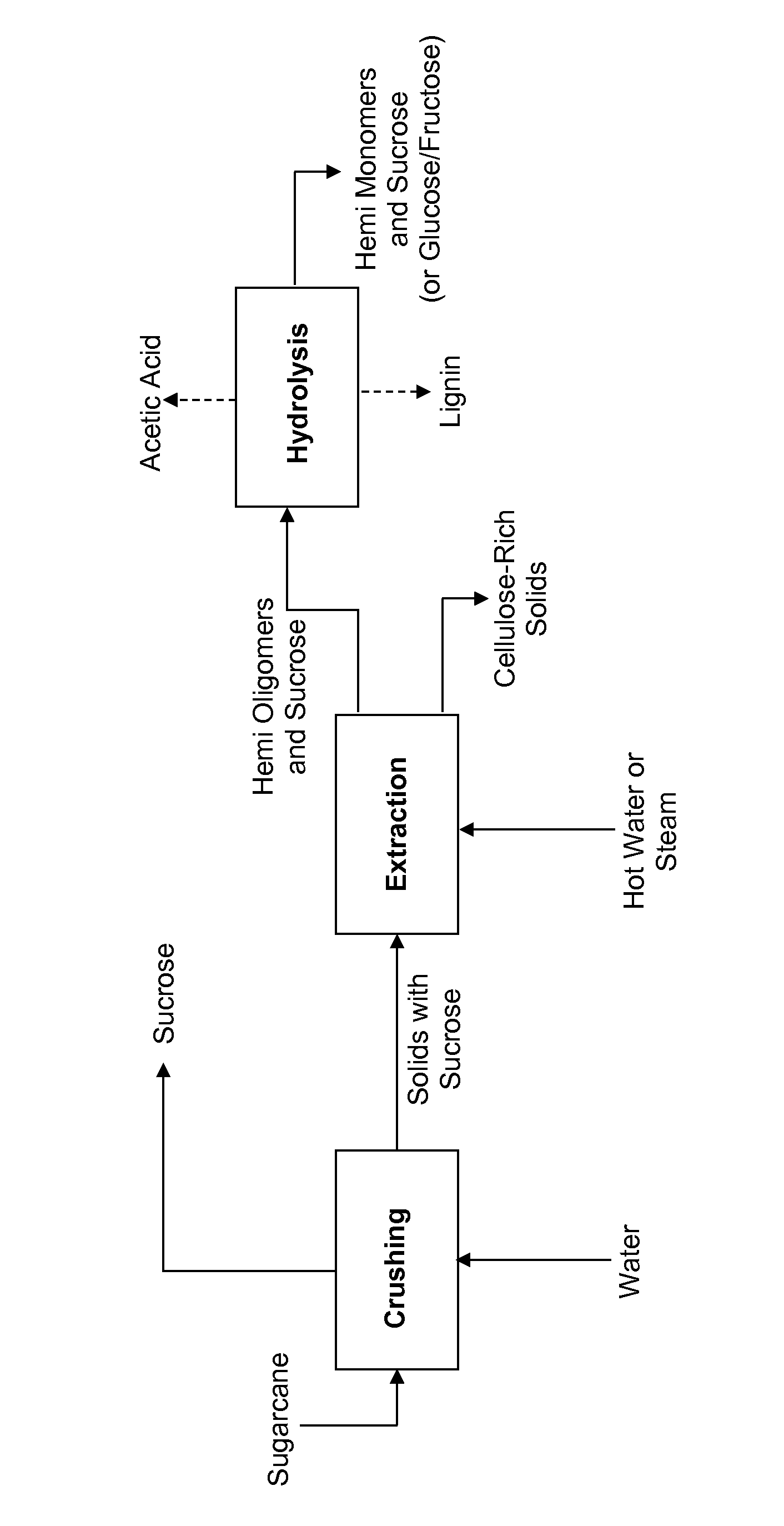

Conventionally, sugarcane processing avoids leaving residual sucrose in the bagasse, since the bagasse will be burned and the value of the sucrose would be lost. However, when coupled with a Green Power+® process to extract hemicelluloses, sucrose may also be extracted and recovered from the bagasse. In some variations, a process includes mechanically treating a feedstock to generate a sucrose-rich stream and lignocellulosic material that intentionally retains a significant amount of the initial sucrose in the feedstock; extracting the lignocellulosic material with steam and / or hot water to produce cellulose-rich solids and an extract liquor containing hemicellulosic oligomers and sucrose; and then hydrolyzing the hemicellulosic oligomers into a hemicellulose sugar stream. Each of the sucrose-rich stream and the hemicellulose sugar stream (containing the starting residual sucrose) may be recovered or further processed (e.g., fermented to ethanol). Similar processes are possible with energy cane, sugar beets, and energy beets.

Owner:GRANBIO INTELLECTUAL PROPERTY HOLDINGS LLC

Complex enzyme detergent for high-temperature-resisting cane sugar manufacturing industry as well as preparation and application thereof

InactiveCN109321553AAchieve the effect of removing impurities and clarifyingImprove qualityPurification by oxidation/reductionPurification using chemicalsPectinaseFiltration

The invention discloses a complex enzyme detergent for a high-temperature-resisting cane sugar manufacturing industry as well as preparation and application thereof and belongs to the technical fieldof clarifying technologies of the sugar manufacturing industry. The complex enzyme detergent is prepared from the following components in percentage by weight: 20 to 50 percent of heat-resisting dextranase, 5 to 35 percent of high-temperature-resisting alpha-amylase, 5 to 25 percent of heat-resisting pectinase, 4 to 20 percent of high-temperature-resisting laccase, 3 to 20 percent of heat-resisting horseradish peroxidase, 3 to 20 percent of high-temperature-resisting cellulase and 0 to 10 percent of water. After raw material enzymes are mixed according to a ratio, a mixture is subjected to membrane filtration and is quantitatively filled to obtain a product. In a process from primary heating to secondary heating, the complex enzyme detergent is added into crude sugar juice to carry out clarification treatment. A complex enzyme preparation formed by a proper ratio prevents a condition that only one enzyme usually cannot reach a predicated impurity removal and clarification effect; a buffering stage does not need to be set, adding sites are wide and the limitation caused by temperature is relatively small.

Owner:广西糖业集团金光制糖有限公司

Concentrated sugarcane juice powder and method for preparing the same using the convection current freeze drying apparatus

ActiveUS10676797B1Increase chanceUniform qualitySugar productsSugar juice conservationFreeze-dryingProcess engineering

A concentrated sugarcane juice powder obtained by a convection current vacuum freeze drying process that includes: selecting and preparing sugarcane stalks by a predetermined quality guideline; extracting sugarcane juice by inserting the sugarcane stalks into a sugarcane juice extracting apparatus having a mesh pattern of micro ridges configured to achieve a maximum extraction efficiency; adding probiotics into the extracted sugarcane juice; freezing the sugarcane juice mixed with the probiotics in molds using an individual quick freezer (IQF) to obtain frozen sugarcane juice blocks; and vacuum freezing said frozen sugarcane juice blocks using a convection current vacuum freeze drying apparatus.

Owner:VINAMIT JSC

Selenium-rich brown sugar preparation method

ActiveCN109136412AFully polysaccharifiedPromote absorptionPurification using microorganisms/enzymesJuice extraction from sugarcaneSugarExcretion

The invention discloses a selenium-rich brown sugar preparation method, and belongs to the field of food processing. The selenium-rich brown sugar preparation method includes the steps: saccharifyingsugarcane squeezing liquid by plant selenium; decocting the saccharified sugarcane squeezing liquid to prepare brown sugar. The selenium-rich brown sugar preparation method ha s the advantages that advantages of ancient brown sugar preparation method are retained, selenium elements in sugarcane can be sufficiently saccharified, so that the selenium elements are easily absorbed, and residual deposition in a body caused by incomplete excretion is avoided.

Owner:海南古遵科技有限公司

Method of making a flavoured sweetener and uses thereof

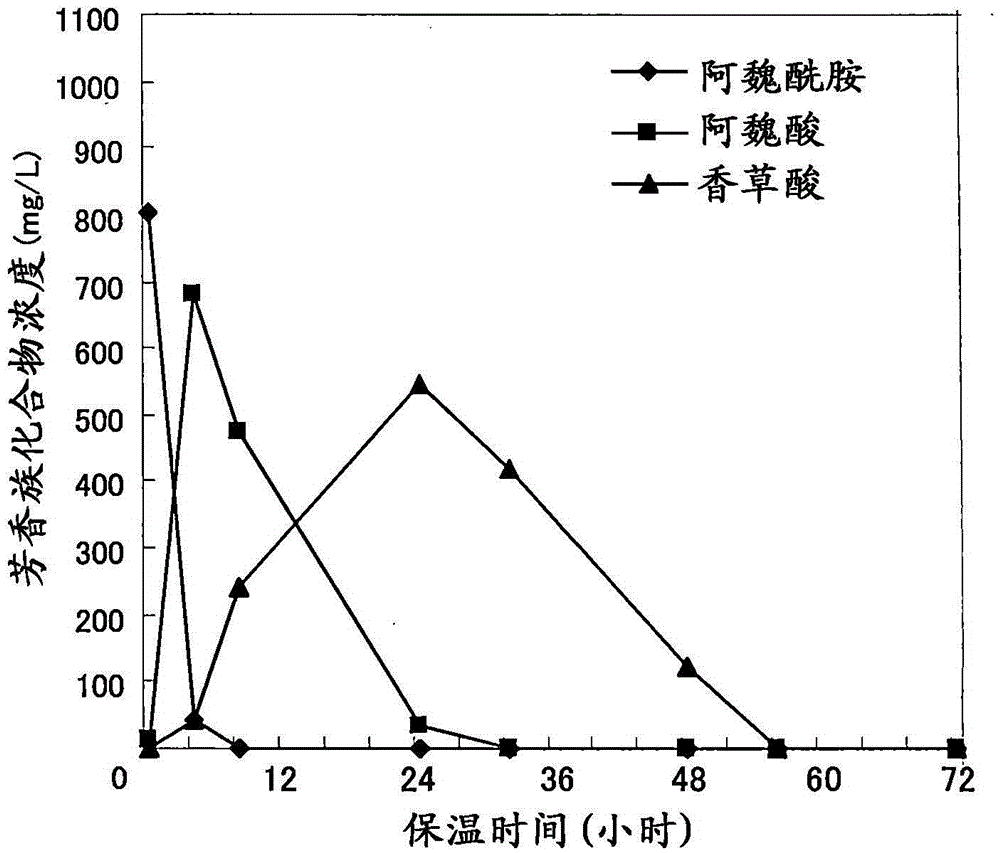

A method of making a flavoured sweetener or food product by incubating an unrefined plant extract containing sucrose as the main solute with a microorganism or microorganisms to form a modified unrefined plant extract; evaporating water from the modified sucrose-based plant extract to form a concentrate; and cooking the concentrate to develop colour and flavour to produce the flavoured sweetener is disclosed. The flavoured sweetener can serve as a coconut sugar substitute. In a preferred embodiment the unrefined plant extract comprises sugarcane juice or sugar beet juice, and the microorganisms may be selected from Stenotrophomonas maltophilia, Bacillus subtilis, Bacillus flexus, or a Klyveromyces species. The flavoured sweetener can be used to make a range of food and beverage ingredientsand also food products including sauces, natural flavour extracts and flavour molecules, chocolate, health foods and convenience forms of the various forms of flavoured sweeteners.

Owner:COCONUTZ PTE LTD

Additive-free liquid brown sugar and preparation method thereof

InactiveCN109295262AEasy to recycleImprove stabilitySugar productsConfectioneryFood additiveMicroorganism

The invention discloses an additive-free liquid brown sugar and a preparation method thereof. The additive-free liquid brown sugar is obtained by squeezing, filtering, immobilized sucrase enzymatic hydrolysis, concentrating and thermal reaction of sugarcane used as a raw material. No food additives or chemical reagents are added in the production process of the additive-free liquid brown sugar, and the additive-free green food is produced by using a biological enzyme and physical processing processes. The additive-free liquid brown sugar is in a liquid state at normal temperature, has stable properties, does not crystallize, can keep a very high osmotic pressure to make microorganisms not grow, and can be preserved for a long term without adding a preservative, and the shelf life is 36 months or above. The additive-free liquid brown sugar has the advantages of good mouthfeel, richness in nutrition, reservation of all nutritional components in a sugarcane juice, and high nutritional values.

Owner:YUNNAN RUOGAN BIOTECH CO LTD

Method for sulfur-free clarification of clear juice

InactiveCN107267672APromote hydrolysis reactionFacilitate segmental softeningPurification using chemicalsPurification by physical meansHydrolysateUltrafiltration

The invention discloses a method for sulfur-free clarification of clear juice. The method comprises the following steps: step 1, subjecting sugarcane to squeezing and filtering so as to obtain bagasse and sugarcane juice, continuously adding phosphoric acid into the sugarcane juice under stirring, adding lime milk at the same time, carrying out heating to a boiling state and then carrying out settlement and separation so as to obtain clarified juice; step 2, carrying out steam explosion on the bagasse and collecting bagasse having undergone steam explosion; step 3, sprinkling a compound enzyme solution onto the surface of the bagasse having undergone steam explosion so as to obtain enzymatic hydrolysate; step 4, heating the enzymatic hydrolysate to 65 DEG D, providing a first clear juice container and carrying out settlement and separation so as to obtain first clear liquid; step 5, heating the first clear liquid to 95 DEG C, providing a second clear juice container and carrying out settlement and separation so as to obtain second clear liquid; and step 6, heating the second clear liquid to a boiling state, removing impurities through filtering, carrying out cooling to room temperature and then successively carrying out ultrafiltration, evaporative concentration, crystallization and purging. Sugar prepared in the invention does not contain SO2, so the chromatic value and turbidity value of the prepared sugar are effectively reduced, and the purity and concentration of the prepared sugar are improved.

Owner:陆丽英

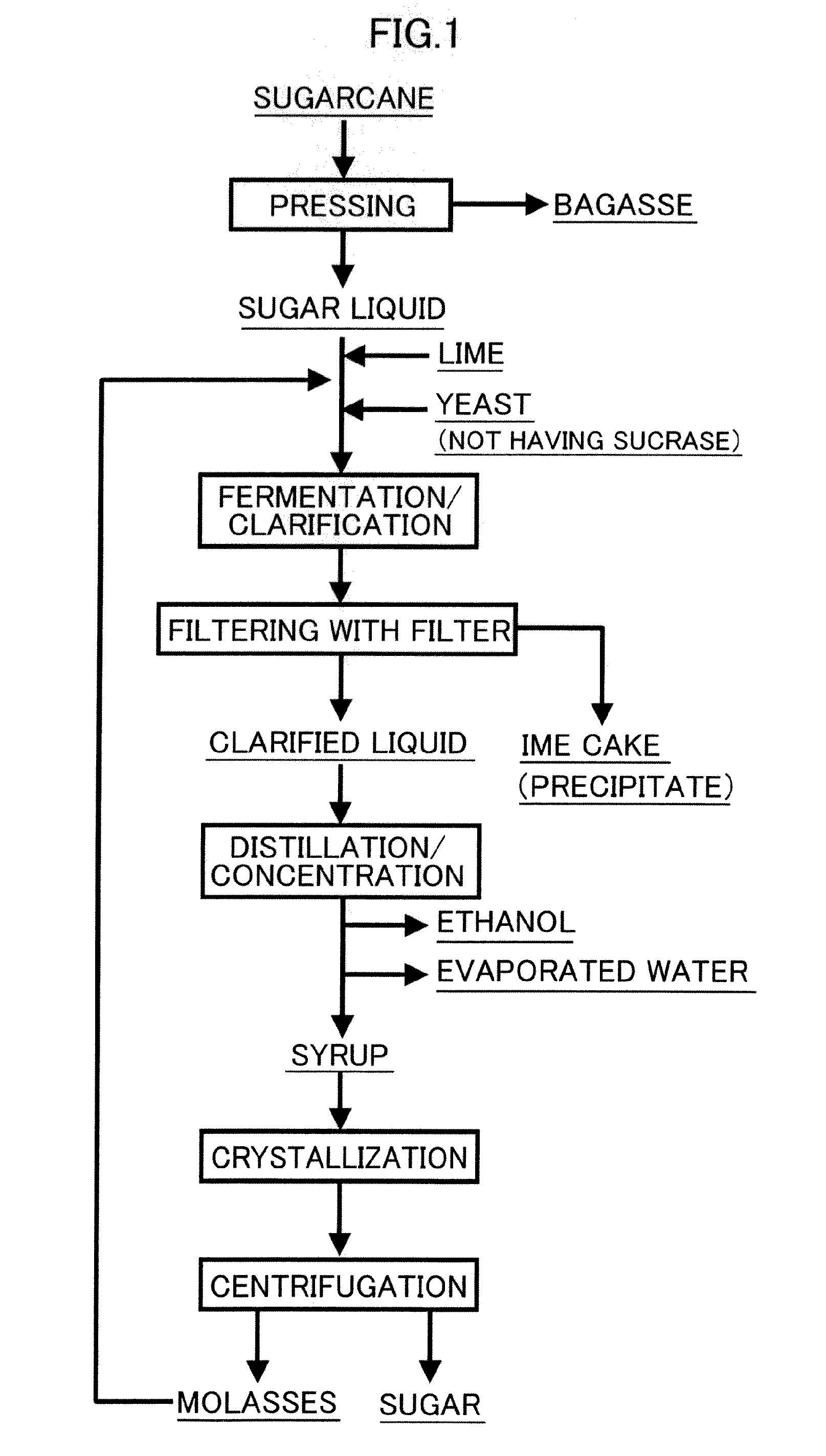

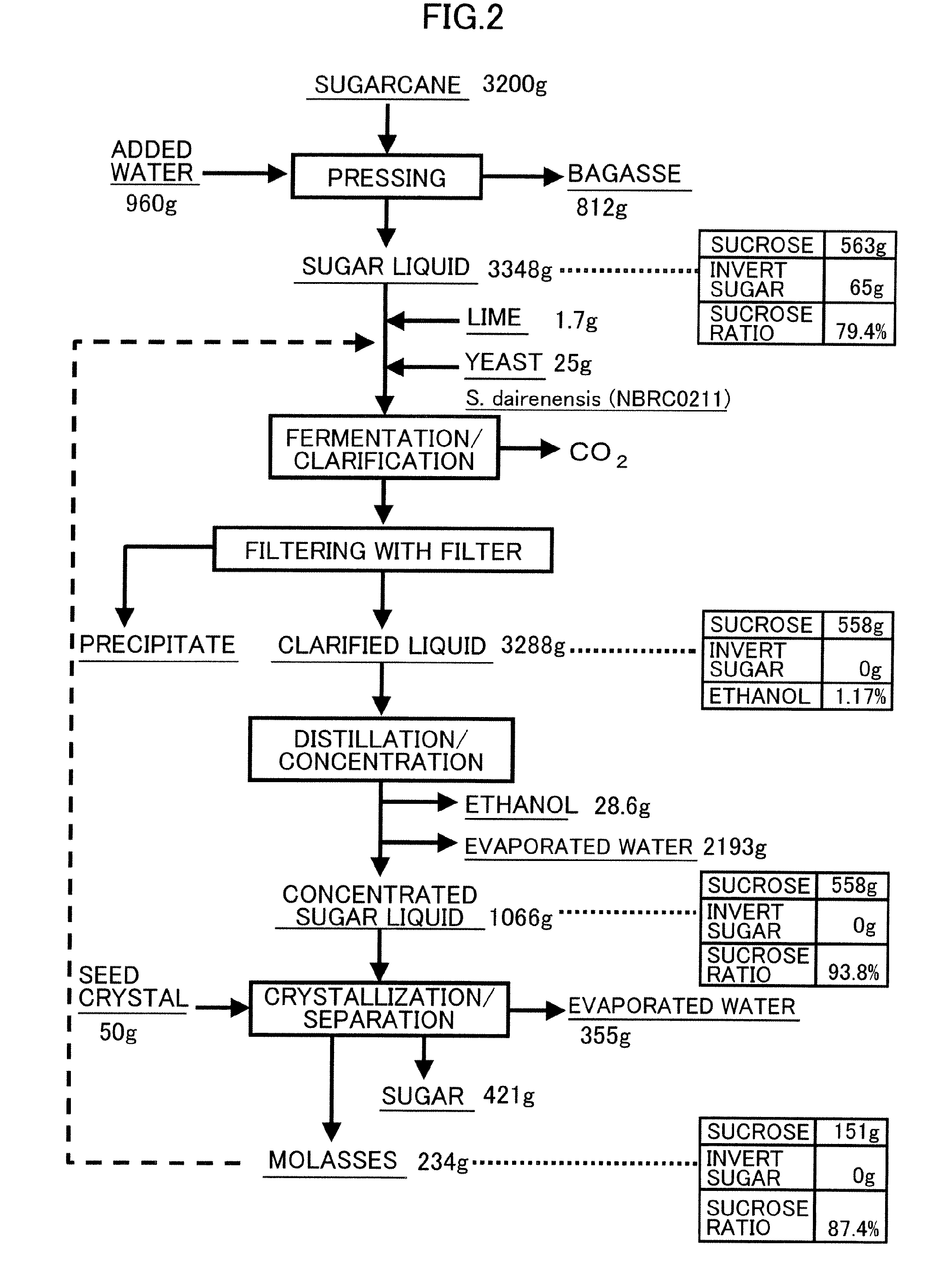

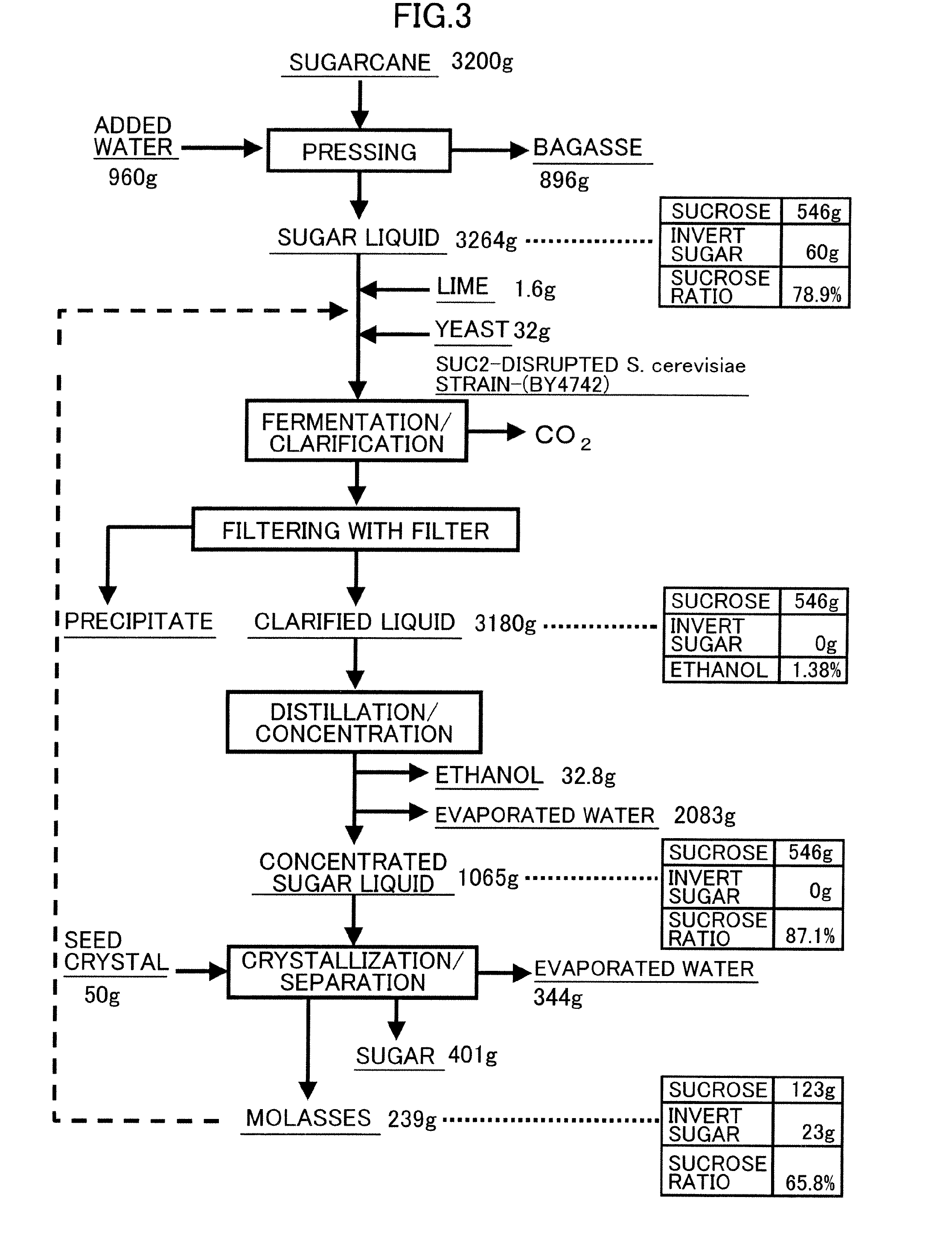

Method for Producing Sugar

InactiveUS20130183724A1Reduce salinityLow in sugar concentrationSugar productsBiofuelsSucroseSaccharophagus degradans

Provided is a method for efficiently producing sugar and simultaneously efficiently producing ethanol. A method for producing sugar characterized by comprising a pretreatment step in which a plant-origin sugar solution is fermented by a microorganism having no sucrose-degrading enzyme and a step for producing sugar from the fermented sugar solution. A method for producing sugar characterized by comprising a pretreatment step in which a plant-origin sugar solution is fermented by a microorganism in the presence of a sucrose-degrading enzyme inhibitor and a step for producing sugar from the fermented sugar solution.

Owner:NAT AGRI & FOOD RES ORG

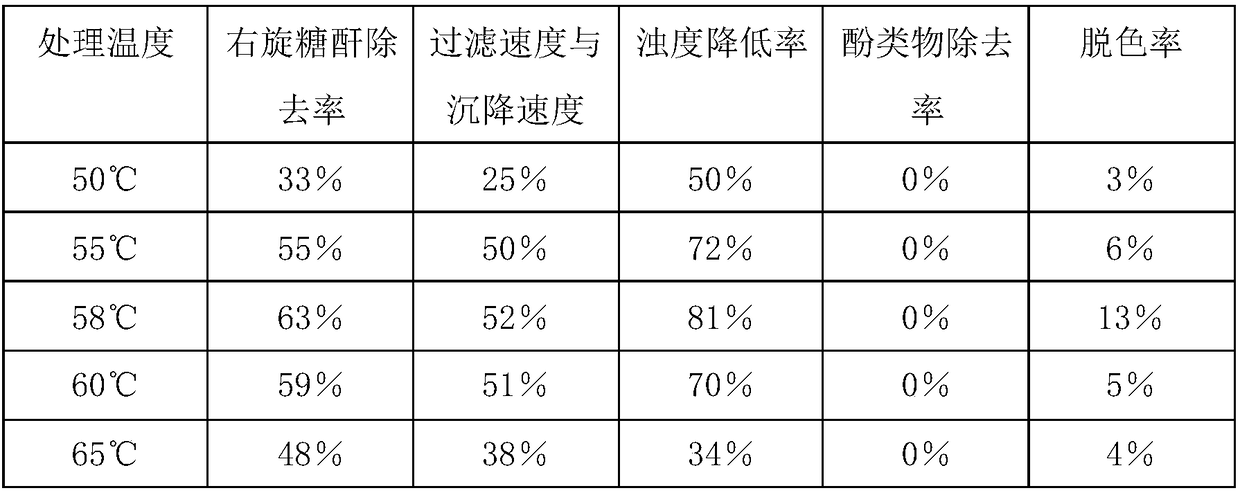

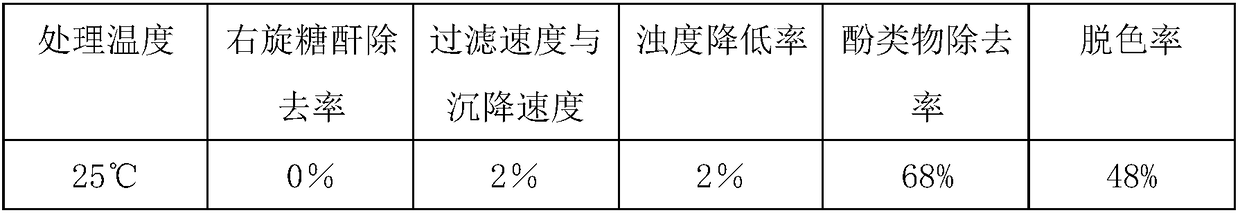

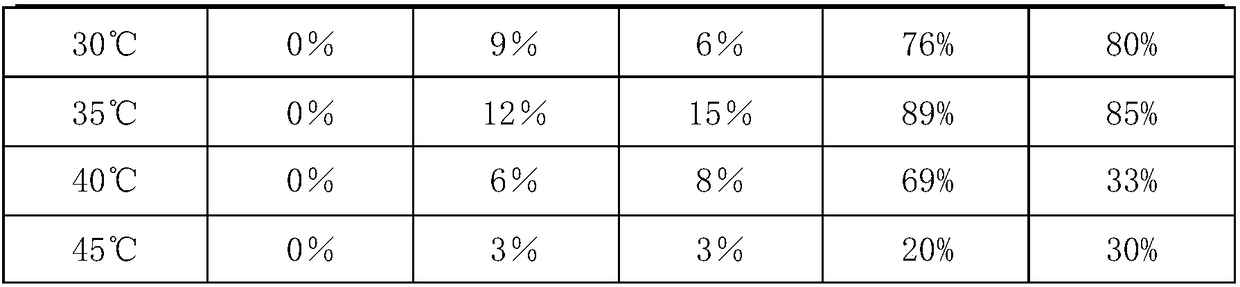

Double-enzyme cleaning process of cane sugar juice

InactiveCN109321684AAvoid the disadvantages of not being highly targeted and having strict requirements on system temperatureReduce contentPurification by physical meansPurification using microorganisms/enzymesCatechol oxidaseTurbidity

The invention discloses a double-enzyme cleaning process of cane sugar juice, belonging to the technical field of a clarification process of the sugar industry. According to the process, enzymes are added in a cane sugar manufacturing sulfite process for hydrolyzing dextranum in the sugar juice, removing phenol and decoloring; the used enzymes are dextranase and catechol oxidase; the process comprises two stages including the hydrolyzing dextranum as well as removing phenol and decoloring. By means of segmented addition use of the two enzymes, the disadvantages of more varieties of the complexenzymes, less target component pertinence and strict requirements on system temperature are avoided; phenol removal and decoloration are realized while the content of the dextranum is reduced; when the dextranase is added for treating the sugar juice, the dextranum removal rate reaches up to 67%, both of the filtering rate and sedimentation rate are increased by about 56%, the turbidity is reduced to 83%, the phenolic removal rate is as high as 92%, and the decoloration rate reaches up to 87%.

Owner:广西糖业集团金光制糖有限公司

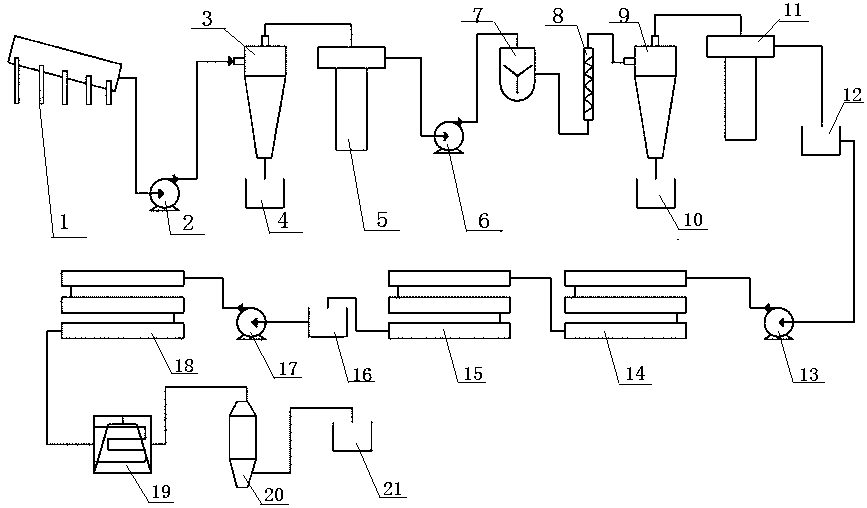

System and technology for continuous film production of beet sugar

ActiveCN109355440AImprove concentration efficiencyReduce chromaSugar crystallisationPurification by physical meansUltrafiltrationReverse osmosis

The invention relates to a system and technology for continuous film production of beet sugar and belongs to the field of sugar making. The system comprises a juice penetration device (1), a liquid rotation device I (3), a high-frequency vibration sieve I (5), a mixer (7), a static mixer (8), a liquid rotation device II (9), a high-frequency vibration sieve II (11), an ultrafiltration membrane (14), a nanofiltration membrane (15), a reverse osmosis membrane unit (18), an evaporator (19) and a crystallizer (20). According to the system for continuous film production of the beet sugar, intelligent continuous operation is achieved, the step of cleaning lime is omitted, and environmental pollution is not caused. Compared with clear juice in the prior art, the sugar degree of the obtained pre-concentrated juice is increased by 10-16 wt%, and the evaporation load can be lowered by 60-70% through increase of the sugar degree; the efficiency is improved, and the cost is lowered.

Owner:四川绿沃创新环保工程有限公司

Method for reducing color value of white granulated sugar by using anthocyanase

InactiveCN109234466AReduce color valueEnsure safetyPurification using microorganisms/enzymesChemistrySugar production

The invention provides a method for reducing a color value of white granulated sugar by using anthocyanase and relates to the technical field of sugar production. The method comprises the following specific steps: adding the anthocyanase into mixed juice or syrup for enzymolysis, wherein the addition amount of the anthocyanase is 0.1 to 0.5U / ml; then adjusting the temperature to 10 to 70 DEG C, keeping at constant temperature for 5 to 60 minutes, and carrying out enzymolysis to realize the effect of reducing the color value. According to the method for reducing the color value of the white granulated sugar by using the anthocyanase, the anthocyanase is used for catalyzing anthocyanin in the mixed juice or the syrup and further the anthocyanin is hydrolyzed into free anthocyanidin and sugar; the anthocyanidin is unstable and is further transformed into a colorless compound, so that the color value of the white granulated sugar is reduced due to fading of the anthocyanin.

Owner:GUANGXI UNIV

Biological treatment method for sulfur-free sugarcane juice clarification

PendingCN110241267ALow impurity contentPromote safe productionPurification by oxidation/reductionPurification using adsorption agentsFlocculationSucrose

The invention belongs to the technical field of cane sugar processing and in particular relates to a biological treatment method for sulfur-free sugarcane juice clarification. The biological treatment method specifically comprises the following operation steps: (1) squeezing sugarcane; (2) carrying out rough filtration treatment; (3) carrying out adjustment; (4) carrying out immobilized enzyme treatment; (5) carrying out flocculation bacterium treatment; (6) carrying out flocculation settling; and (7) carrying out separation, namely outputting upper clear juice obtained in the step (6), carrying out filter press separation on settled muddy juice at a lower layer, and combining the settled muddy juice with the upper clear juice, so as to obtain clear juice. The biological treatment method has the advantages that a high-quality sugar product can be produced, and the food security risk can be reduced. In the process, the amount of lime and phosphoric acid only accounts for 20% or less of that of a common sulfur-free sugar making process, a small amount of filter mud is produced, and the production process is environment-friendly and safe.

Owner:广西浦北县湘桂糖业有限责任公司

Low-carbon and environmental-protection sugaring method based on cane sugar alcohol co-production

The invention provides a cane sugar alcohol co-production low-carbon and environmental-protection sugaring method based on a solid fermentation technique. The method comprises a low-energy-consumption high-quality cane sugar production procedure and a procedure of fermenting and transforming sugar solid, which is residual in molasses and bagasse, into alcohol. By-products can be utilized by the following steps: carbon dioxide generated in the solid fermentation procedure is taken as a clarifying agent applied to cane juice purification; fermentation dregs generated in a solid distillation procedure can be applied to power generation in a bagasse power plant or fodder; waste steam from the bagasse power plant is applied to alcohol separation and / or cane juice in the solid distillation procedure. According to the low-carbon and environmental-protection sugaring method, cane sugar in sugarcane can be utilized to the maximum extent, the production costs of the cane sugar and the energy consumption are reduced, sugar is produced, and alcohol fuel is also produced; due to a solid fermentation technique, the quantity of organic sewage generated in the production procedure is reduced; the by-products, such as the carbon dioxide, the fermentation dregs and the waste steam, can be comprehensively utilized.

Owner:TSINGHUA UNIV

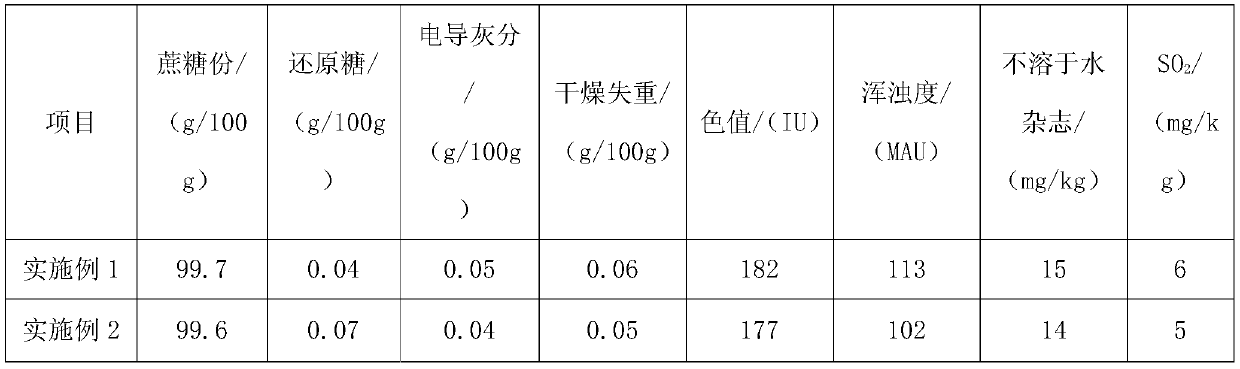

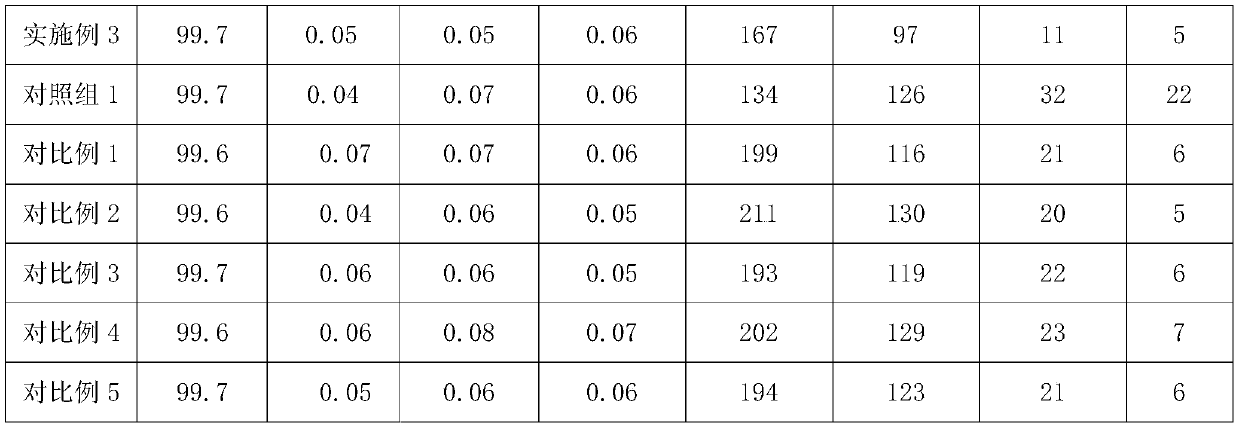

Special compound enzyme preparation for sugar production and preparation method and application of special compound enzyme preparation

ActiveCN112048496ALow viscosityAids in absorbencyOxidoreductasesGlycosylasesPectinaseOxidative enzyme

The invention relates to the technical field of cane sugar making clarification, and particularly discloses a special compound enzyme preparation for sugar production. The special compound enzyme preparation comprises the following components in percentage by weight: 40-48% of dextranase, 18-25% of pectinase, 8-12% of cellulase, 4-6% of polyphenol oxidase, 4-6% of papain, 8-12% of magnesium chloride and 3-6% of poly dimethyl diallyl ammonium chloride. The invention also provides a preparation method of the special compound enzyme preparation for sugar production. A complex enzyme preparation is added to sugarcane squeezed juice for clarification treatment, the viscosity of sugar juice is obviously reduced, a certain viscosity reducing effect is achieved in the sugar boiling process, absorption and crystallization of sucrose molecules are facilitated, the color value of a finished product is reduced by 20-30%, the turbidity is reduced by 30% or above, water-insoluble impurities are reduced by 20-30%, the simple purity is improved, the sucrose recovery rate is increased, and waste molasses yield can be reduced.

Owner:南宁雄晋生物科技有限公司

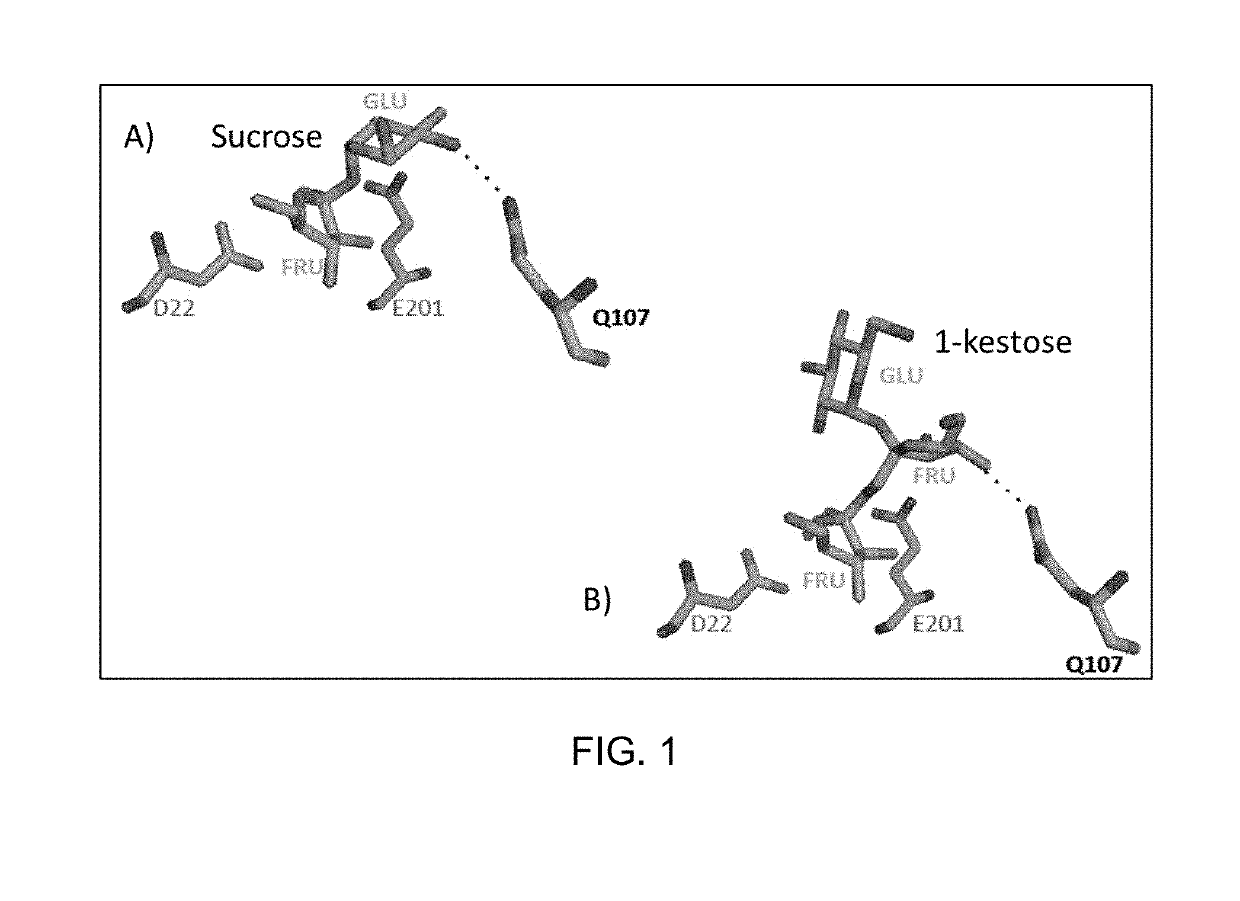

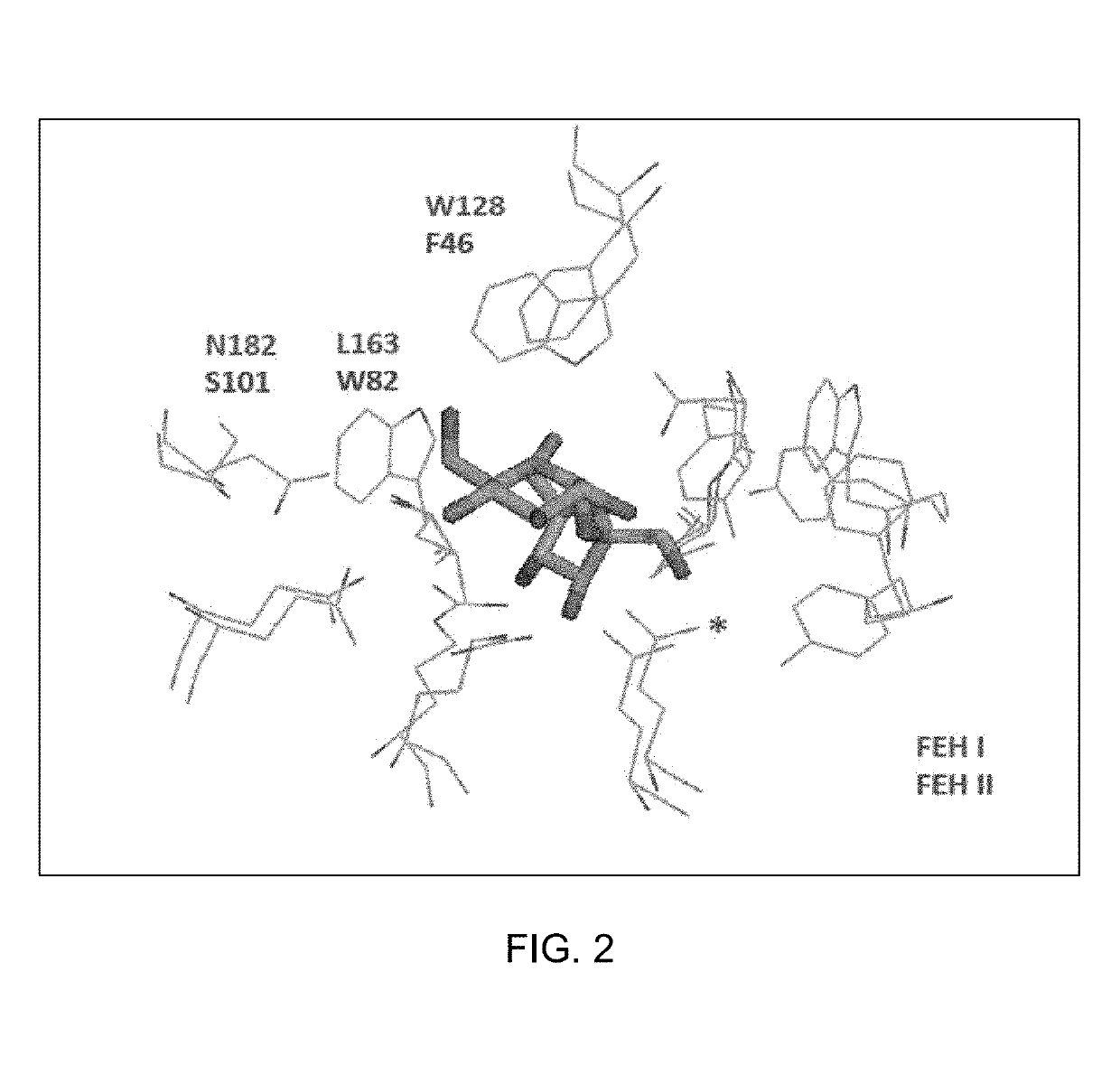

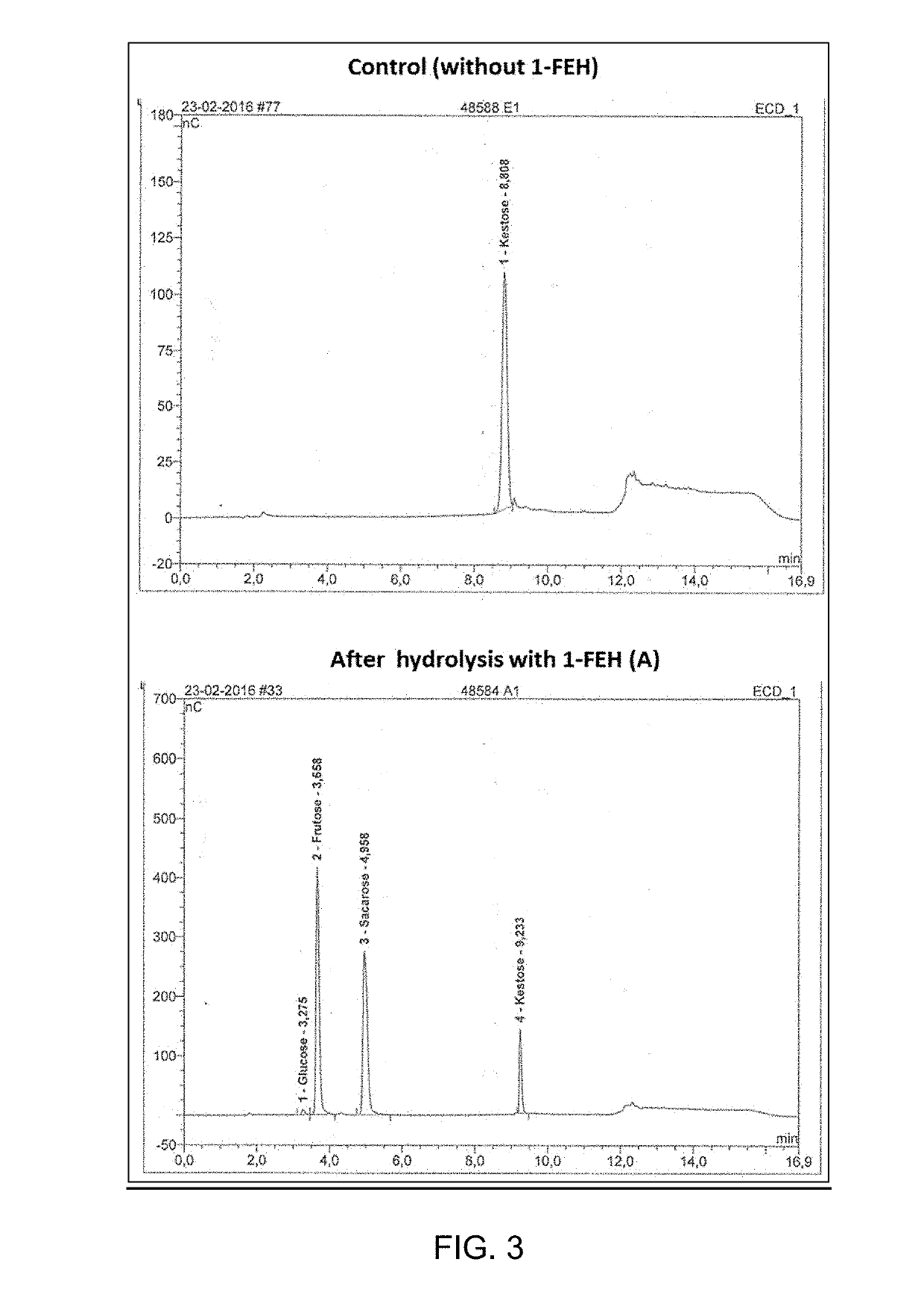

Polypeptides having hydrolytic activity on 1-kestose in the presence of sucrose but lacking sucrase (invertase) activity, polynucleotides encoding same and methods of producting and using same in industrial sucrose production from 1-kestose

ActiveUS20190276864A1Efficient and advantageous and economically viableHydrolasesFermentationFructoseEnzymatic hydrolysis

An industrial process using kestose hydrolases to enable the use of sugar mixtures containing 1-kestose in the industrial production of sucrose (as crystallized sugar) by providing a method for the conversion of 1-kestose into sucrose and fructose in a sugar solution, containing kestose and more than 10 mM sucrose (3 g / L), and comprising the enzymatic hydrolysis (preferably using 1-FEH enzymes—EC 3.2.1.153) of 1-kestose. The process further provides a method of producing a polypeptide having 1-kestose hydrolase activity and a composition comprising the polypeptide.

Owner:CTC CENT DE TECHA CANAVIEIRA

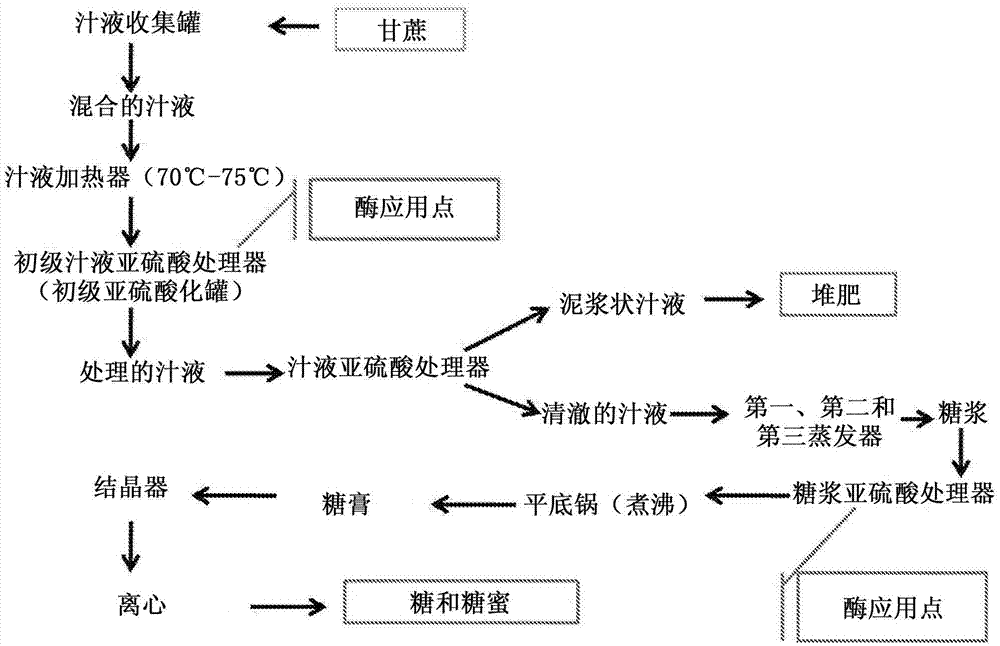

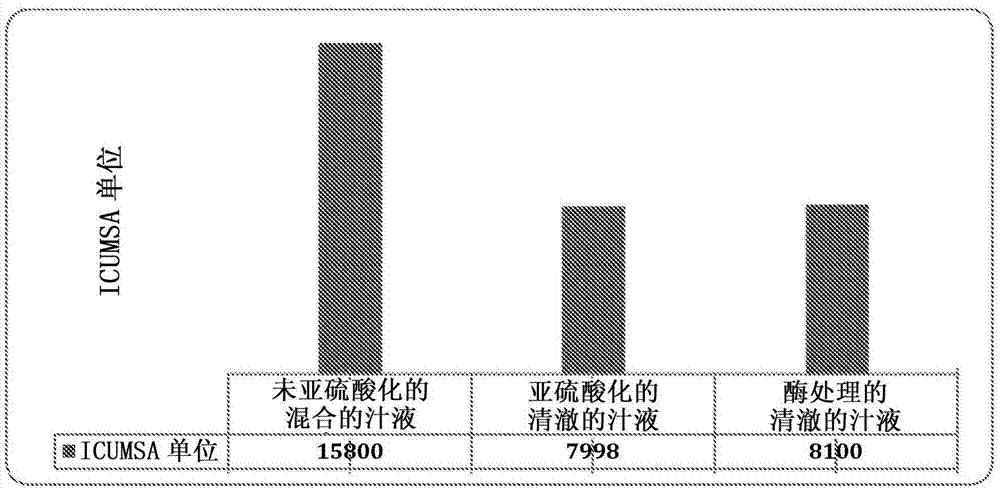

Composition, process and kit for sugar processing

The present disclosure relates to an enzyme based sulphur replacement product, an enzyme based sulphur replacement process and a kit applicable in sugar processing. The present disclosure also relates to a composition comprising an enzyme blend employed in the process for obtaining a sulphur replacement product; and a final product obtained after the sugar processing.

Owner:RICHCORE LIFESCI PVT

A low-carbon, environmentally friendly sugar production method based on co-production of sugar cane sugar alcohol

The invention provides a cane sugar alcohol co-production low-carbon and environmental-protection sugaring method based on a solid fermentation technique. The method comprises a low-energy-consumption high-quality cane sugar production procedure and a procedure of fermenting and transforming sugar solid, which is residual in molasses and bagasse, into alcohol. By-products can be utilized by the following steps: carbon dioxide generated in the solid fermentation procedure is taken as a clarifying agent applied to cane juice purification; fermentation dregs generated in a solid distillation procedure can be applied to power generation in a bagasse power plant or fodder; waste steam from the bagasse power plant is applied to alcohol separation and / or cane juice in the solid distillation procedure. According to the low-carbon and environmental-protection sugaring method, cane sugar in sugarcane can be utilized to the maximum extent, the production costs of the cane sugar and the energy consumption are reduced, sugar is produced, and alcohol fuel is also produced; due to a solid fermentation technique, the quantity of organic sewage generated in the production procedure is reduced; the by-products, such as the carbon dioxide, the fermentation dregs and the waste steam, can be comprehensively utilized.

Owner:TSINGHUA UNIV

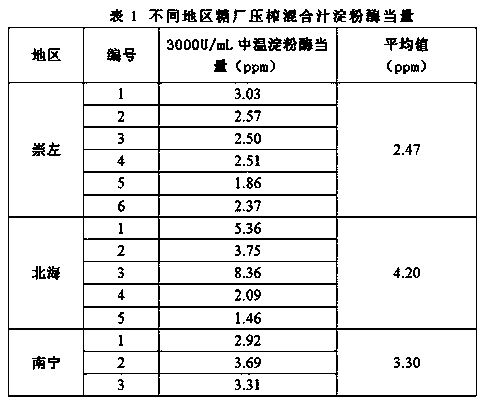

Clarifying method for removing starch in sugar making process

PendingCN110343787AAvoid foulingImprove filtering effectPurification using alkaline earth metal compoundsPurification using microorganisms/enzymesAmylaseStarch gelatinization

The invention relates to the technical field of sugarcane sugar making, and relates to a clarifying method for removing starch in a sugar making process. The method comprises the following steps: step1, carrying out preliming; step 2, carrying out primary heating; step 3, carrying out main liming; step 4, degrading starch by amylase; and step 5, carrying out secondary heating. Compared with the prior art, the method has the advantages that starch in primary sugarcane juice is skillfully gelatinized by primary heating, and then activity of the amylase is fully exerted by prolonging the retention time of tertiary sugarcane juice, so that adverse effects of starch on the sugar making process are removed; then natural amylase is inactivated by secondary heating, so that residual natural amylase in the final product is avoided; and in addition, a reaction of phosphoric acid and lime milk is enhanced by prolonging the retention time of the squeezed mixed juice, so that the effect of clarification process and filtering performance of mud juice are improved, and meanwhile, scaling in an evaporation tank and a sugar boiling tank caused by lag of an acid-base reaction is avoided.

Owner:中粮崇左糖业有限公司 +2

Sugar solution production method

Although various fermentation inhibitors are contained in the aqueous sugar solution obtained from biomass, they can be removed easily and at low cost by treating the aqueous sugar solution with microorganisms that do not have the ability to assimilate glucose and xylose or crude enzymes derived from the microorganisms. Fermentation inhibitory substances derived from biomass.

Owner:TORAY IND INC

High-efficiency composite clarifying agent used for clarification and decolorization of sugar liquid

ActiveCN110387441ALarge specific surface areaImprove adsorption capacityPurification using adsorption agentsOther chemical processesCalcium biphosphatePectinase

The invention discloses a high-efficiency composite clarifying agent used for clarification and decolorization of a sugar liquid. The high-efficiency composite clarifying agent is composed of the following components in parts by weight: 100 to 200 parts of modified calcium phosphate, 2 to 5 parts of polyphenol oxidase and 2 to 5 parts of pectinase. The preparation method for the composite clarifying agent comprises the following steps: weighing the polyphenol oxidase and the pectinase according to the amounts described in the formula, dissolving the weighed polyphenol oxidase and pectinase into a phosphate buffer solution so as to obtain an enzyme mixed solution, then weighing the modified calcium phosphate according to the amount described in the formula, adding the modified calcium phosphate into the enzyme mixed solution under the condition of stirring, carrying out oscillating adsorption at 10 to 20 DEG C for 2 to 6 hours, and carrying out drying under a vacuum condition so as to obtain the high-efficiency composite clarifying agent used for clarification and decolorization of the sugar liquid. The high-efficiency composite clarifying agent provided by the invention is used forclarification and decolorization of the sugar liquid, can improve the efficiency of a decolorization procedure in sugar preparation, and reduces the production cost of sugar preparation.

Owner:NANNING XIAYANG CHEM TECH CO LTD

A kind of preparation method of selenium-enriched brown sugar

ActiveCN109136412BFully polysaccharifiedPromote absorptionPurification using microorganisms/enzymesJuice extraction from sugarcaneBiotechnologyChaptalization

The invention discloses a preparation method of selenium-enriched brown sugar, which belongs to the field of food processing. A method for preparing selenium-enriched brown sugar of the present invention comprises the step of boiling sugarcane squeezed liquid into brown sugar after undergoing plant selenium polysaccharification. The method for preparing selenium-enriched brown sugar of the present invention has the advantages of retaining the advantages of the brown sugar produced by the ancient method, and can fully polysaccharify the selenium element in sugarcane, which is easy to be absorbed by the human body, and will not cause incomplete excretion and residual accumulation in the body .

Owner:海南古遵科技有限公司

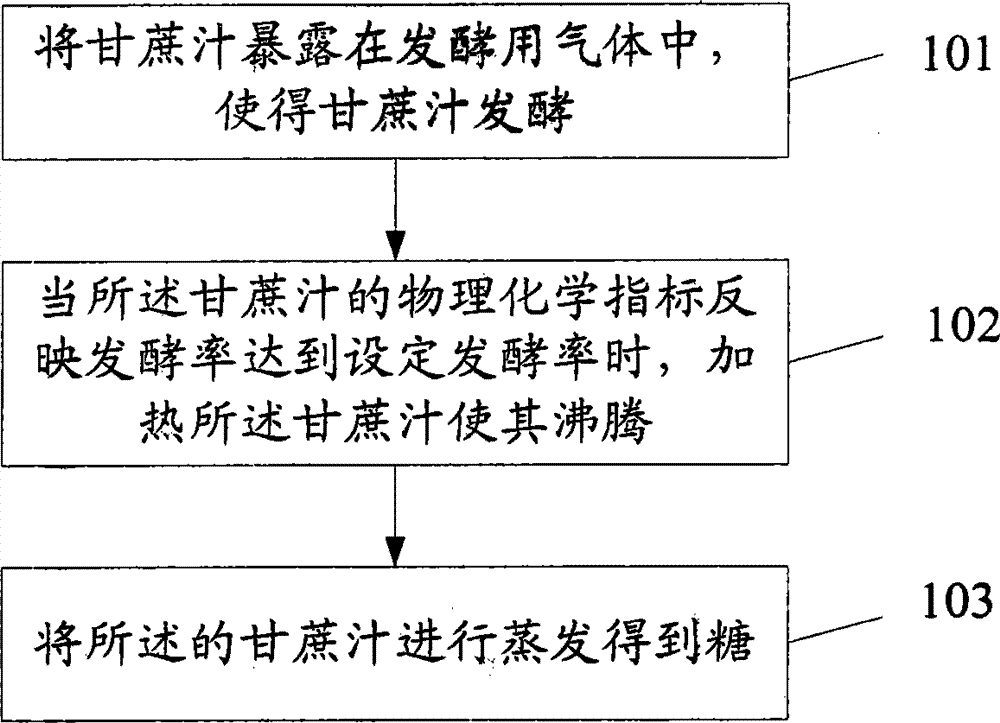

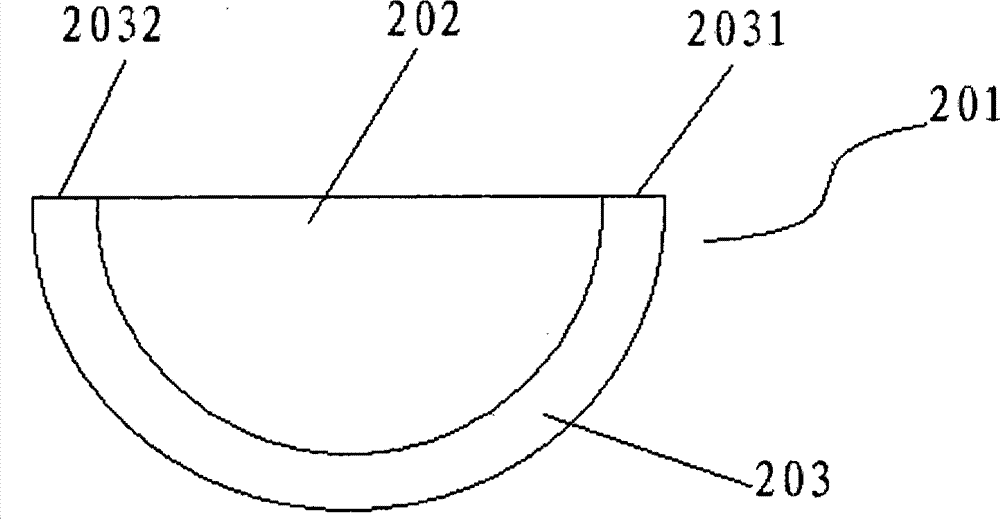

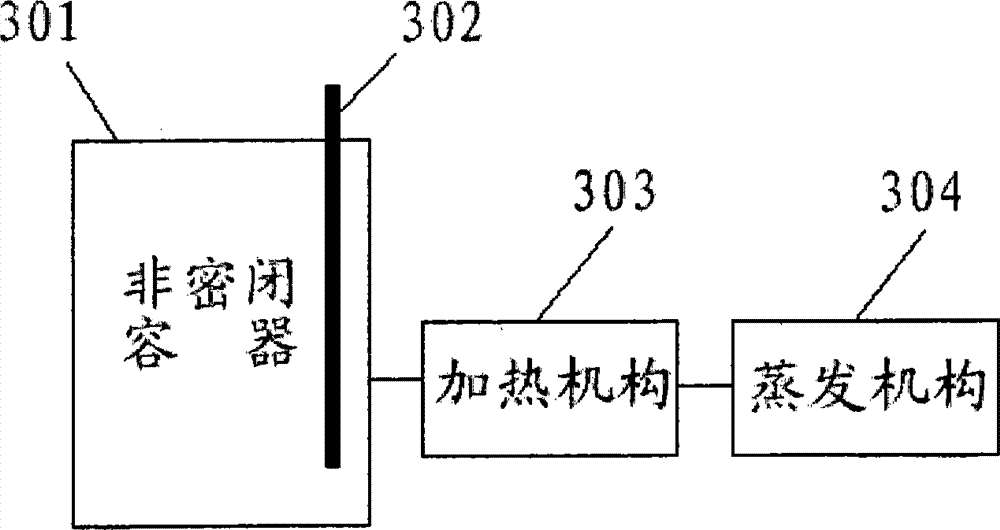

Method and device for refining sugar

ActiveCN104726619AChange physical propertiesSmall physical propertiesSugar productsSugar juice boiling/evaporationChemical indexSugar

The invention discloses a method and a device for refining sugar. The method comprises the following steps: exposing sugarcane juice in gas for fermentation so as to ferment the sugarcane juice; heating the sugarcane juice so as to boil the sugarcane juice when the fermentation rate reaches a preset fermentation rate according to the physical and chemical indexes of the sugarcane juice; and evaporating the sugarcane juice to obtain the sugar, wherein the preset fermentation rate is greater than 0. The device comprises a non-closed container, a fermentation rate detection mechanism, a heating mechanism and an evaporating mechanism. By adopting the method and the device which are provided by the invention, the sugar which is more soft and smooth is prepared, and the mouthfeel of the sugar product is improved.

Owner:王连升

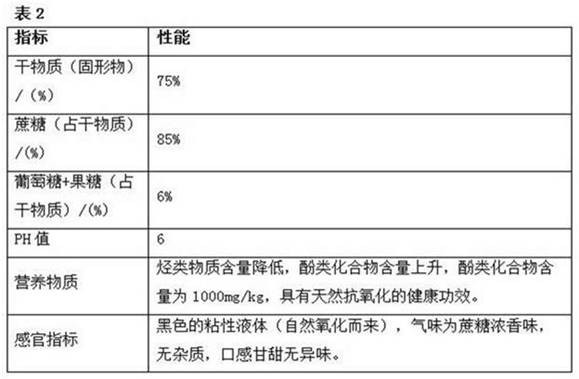

self-fermenting syrup

ActiveCN107385118BHigh nutritional valueReduce pollutionSugar productsPurification by physical meansBiotechnologyNutritive values

The invention discloses a self-fermentation syrup, relates to the field of sugar production, and especially relates to a self-fermentation syrup having a good quality and directly used for producing sugar. The syrup is produced through adopting a sealed anaerobic fermentation technology. The syrup is produced through the following concrete steps: juicing sugarcane, filtering and boiling the obtained juice to produce maltose, mixing the maltose with air-dried sugarcane, filling a sealed tank with the mixture, sealing the tank, and carrying out sealed anaerobic fermentation for 2-3 months to produce the syrup. The shelf life of the syrup reaches 2 years, the sugar production time is effectively prolonged, a producer can momentarily produce the sugar from the syrup as needed, and the syrup is produced by adopting the anaerobic fermentation technology, so the process is simple, the reduction of the sugar production cost is facilitated, the sugar production efficiency is improved, and the economic benefit of enterprises is increased. The syrup has high nutritional values, has natural anti-oxidation healthy effects, can be directly processed to make the sugar, can effectively reduce the safety problem of foods, is beneficial to the health of bodies, and has a high market promotion value.

Owner:云南宽谷糖业有限公司

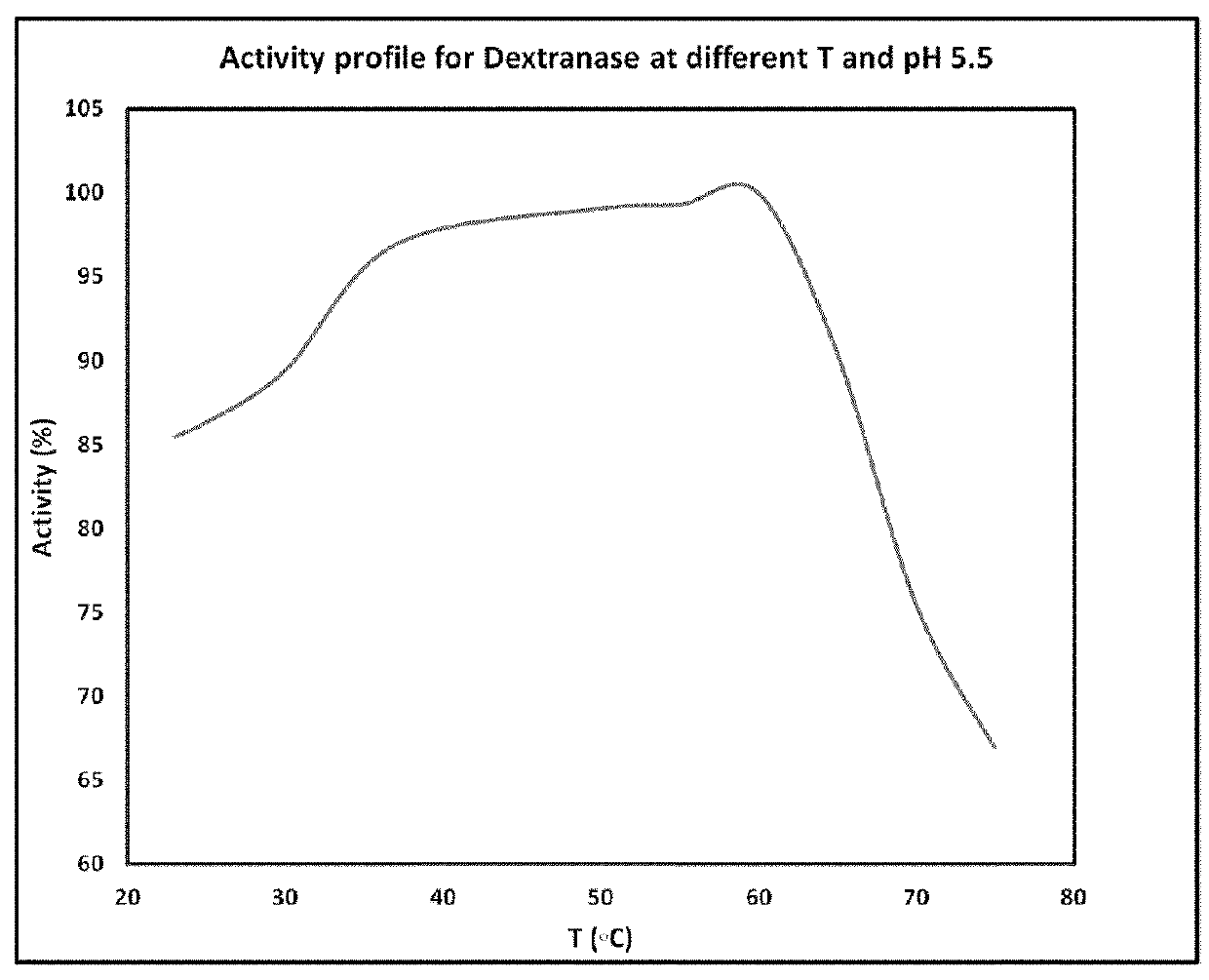

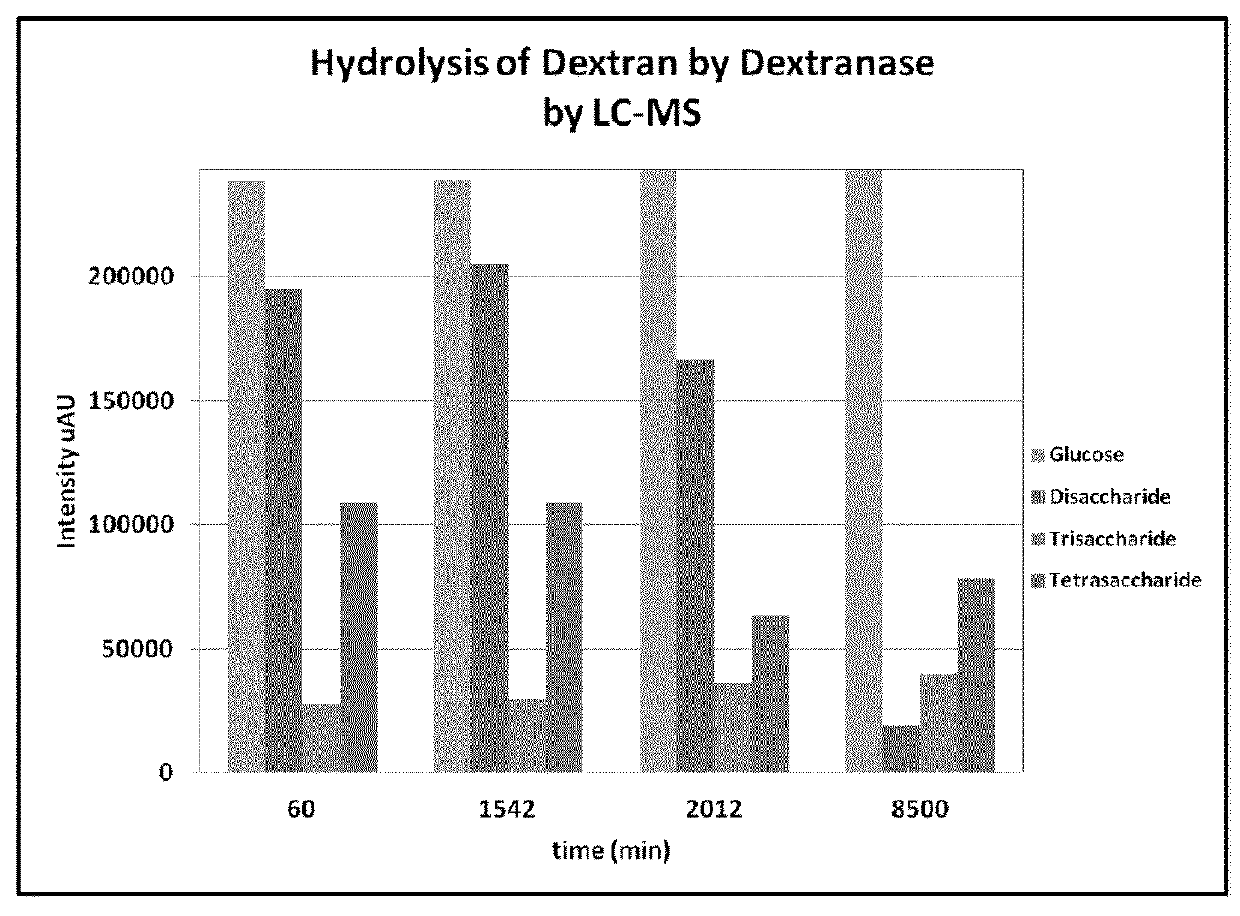

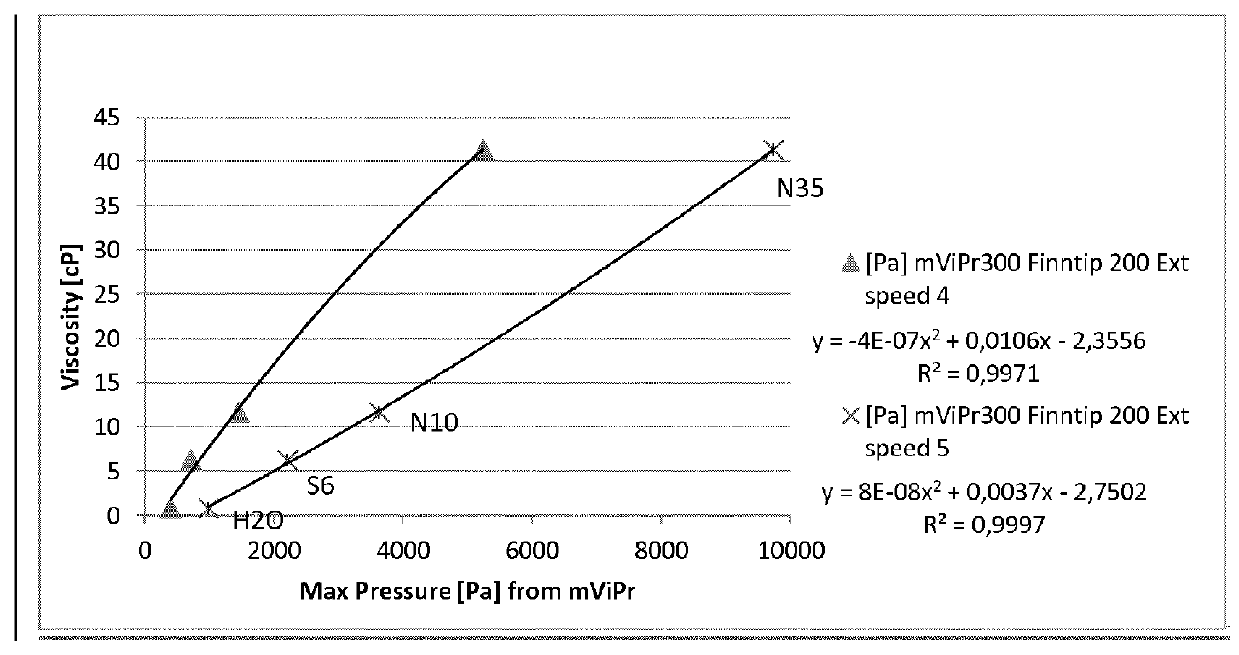

Polypeptides having dextranase activity and polynucleotides encoding same

The present invention relates to isolated polypeptides having dextranaseactivity, and polynucleotides encoding the polypeptides. The invention also relates to nucleic acid constructs, vectors, and host cells comprising the polynucleotides as well as methods of producing and using the polypeptides.

Owner:NOVOZYMES AS

Processes and apparatus for refining sugarcane to produce sugars, biofuels, and/or biochemicals

Owner:GRANBIO INTELLECTUAL PROPERTY HOLDINGS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com