self-fermenting syrup

A self-fermentation and syrup technology, which is applied in sugar products, sucrose production, sugar production, etc., can solve the problems of syrup waste, instability, complex syrup quality, etc., achieve simple process, reduce sugar production cost, and improve sugar production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Self-fermenting syrup, the syrup adopts sealed anaerobic fermentation technology to prepare syrup, and the syrup preparation steps are as follows:

[0019] (1) Squeeze the sugarcane juice and then filter and boil it to make syrup, the syrup has a Brix of 70°Bx;

[0020] (2) Wash the sugarcane, and then air-dry it for 48 hours to make it slightly smell of alcohol;

[0021] (3) Mix the air-dried sugarcane into the syrup. The mass ratio of sugarcane to syrup is 1:100. After mixing, put the syrup into a sealed tank for sealing and anaerobic fermentation. During the anaerobic fermentation, the temperature is controlled at 26°C, humidity controlled at 77%;

[0022] (4) After two months of sealing, open the sealed tank, take out the sugar cane mixed in the syrup, and obtain the syrup.

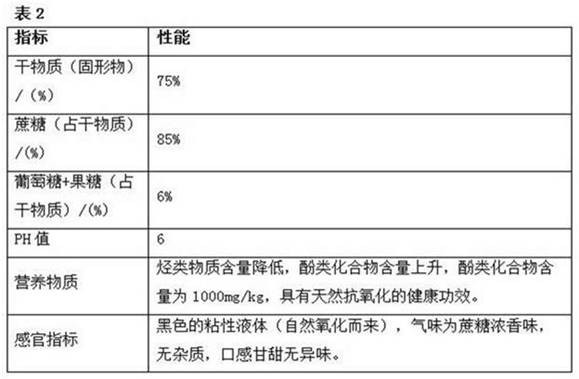

[0023] The properties of the syrup prepared in this embodiment are shown in Table 1 below.

[0024]

[0025] Gained syrup can be directly used as making sugar cubes, and the preparation s...

Embodiment 2

[0030] Self-fermenting syrup, the syrup adopts sealed anaerobic fermentation technology to prepare syrup, and the syrup preparation steps are as follows:

[0031] (1) Squeeze the sugarcane juice and then filter and boil it to make syrup, the syrup has a Brix of 75°Bx;

[0032] (2) Wash the sugarcane, and then air-dry it for 48 hours to make it slightly smell of alcohol;

[0033] (3) Mix the air-dried sugarcane into the syrup. The mass ratio of sugarcane to syrup is 1:100. After mixing, put the syrup into a sealed tank for sealing and anaerobic fermentation. During the anaerobic fermentation, the temperature is controlled at 35°C, humidity controlled at 82%;

[0034] (4) After sealing for 3 months, open the sealed tank and take out the sugar cane mixed in the syrup to obtain the syrup.

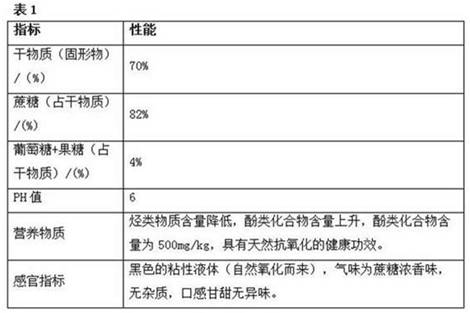

[0035] The properties of the syrup prepared in this embodiment are shown in Table 2 below.

[0036]

[0037] Gained syrup can be directly used as making sugar cubes, and the preparation s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com