System and technology for continuous film production of beet sugar

A technology of beet sugar and continuous membrane, which is applied in the direction of sugar leaching from beet, sucrose production, sugar production, etc., can solve the problems of sugar juice degradation, low sugar production efficiency, and decline in sugar juice quality, and achieve the reduction of non-sugar production. Content of molecular substances, reduction of risk of degradation and darkening, effect of reducing color and turbidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

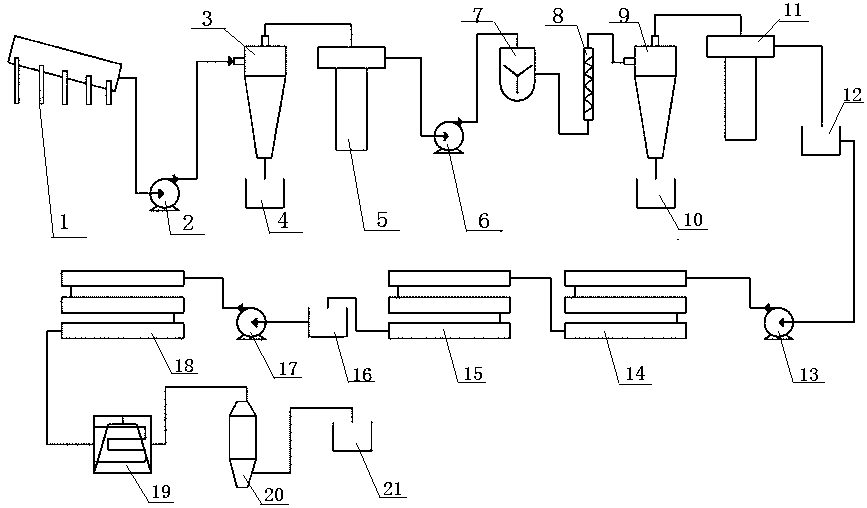

[0029] A continuous membrane production system for beet sugar, including juice permeator 1, pump I2, liquid cyclone I3, high-frequency vibrating screen I5, pump II6, mixer 7, static mixer 8, liquid cyclone II9, high-frequency vibration Sieve II 11, pump III 13, ultrafiltration membrane 14, nanofiltration membrane 15, pump IV 17, reverse osmosis membrane group 18, evaporator 19 and crystallizer 20;

[0030] The liquid outlet pipeline of the juice percolator 1 is connected to the liquid inlet of the liquid cyclone I3, and a pump I2 is arranged between the juice permeator 1 and the liquid cyclone I3, and the liquid outlet at the upper end of the liquid cyclone I3 passes through the pipeline and the liquid cyclone I3. The liquid inlet of the high-frequency vibrating screen I5 is connected, the liquid outlet of the high-frequency vibrating screen I5 is connected with the liquid inlet of the mixer 7 through a pipeline, and a pump II6 is arranged between the high-frequency vibrating s...

Embodiment 1

[0037] A method for producing beet sugar based on the continuous membrane of the above-mentioned system, comprising the following steps:

[0038] (1) Pretreatment: after the beet is washed and shredded, the sugar in the beet is extracted in the exudator 1 with water as a solvent to obtain beet juice;

[0039] (2) Impurity removal: use hydrocyclone I3 to remove large particles of impurities such as silt and vegetable dregs mixed in the beet juice, and then use high-frequency vibrating screen I5 to remove tiny particles of impurities in the beet juice. The operating temperature of the coupling of liquid vessel I3 and high frequency vibrating screen I5 is 60°C;

[0040] (3) Enzymolysis: the beet juice after impurity removal is mixed evenly with compound enzyme in mixer 7, and described compound enzyme is made up of pectinase and amylase, and the mass ratio of pectinase and amylase is 4:1, The amount of compound enzyme added is to add 10 mg of compound enzyme in every 1L of beet ...

Embodiment 2

[0048] A method for producing beet sugar based on the continuous membrane of the above-mentioned system, comprising the following steps:

[0049] (1) Pretreatment: after the beet is washed and shredded, the sugar in the beet is extracted in the exudator 1 with water as a solvent to obtain beet juice;

[0050] (2) Impurity removal: use hydrocyclone I3 to remove large particles of impurities such as silt and vegetable dregs mixed in the beet juice, and then use high-frequency vibrating screen I5 to remove tiny particles of impurities in the beet juice. The operating temperature of liquid vessel Ⅰ3 and high frequency vibrating screen Ⅰ5 are both 70°C;

[0051] (3) Enzymolysis: the beet juice after impurity removal is mixed evenly with compound enzyme in mixer 7, and described compound enzyme is made up of pectinase and amylase, and the mass ratio of pectinase and amylase is 4:1, The amount of compound enzyme added is to add 10 mg of compound enzyme in every 1L of beet juice, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com