Composition, process and kit for sugar processing

A composition, mixture technology, applied in the production of sugar, purification of juice, purification using microorganisms/enzymes, etc., can solve problems such as reduction or even elimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0106] Extraction of sugar juice:

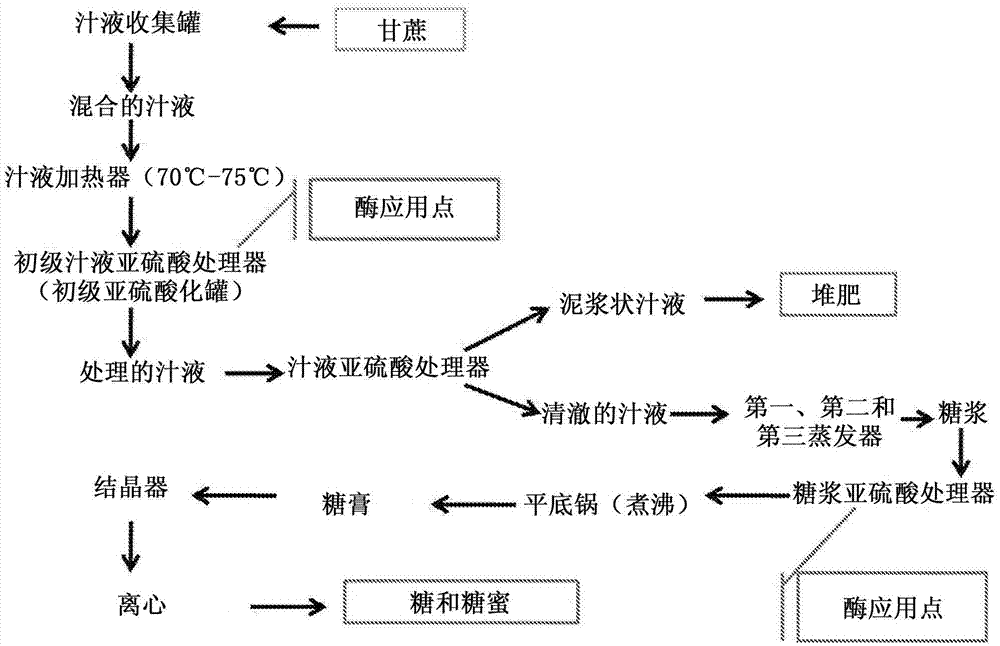

[0107] Sugarcane juice / sugar juice extraction is usually a continuous process, which involves three mills / crushers. The grinder can be a roller type or a mallet type. During crushing, the node of cane is destroyed and the stem is flattened to extract juice. The juice is collected from each grinder during the first crushing and is referred to as the primary juice. The poorer juices collected in the subsequent grinding are reprocessed and hot water is usually applied to the final grinder to maximize extraction. The mixed juice is the combination of the juice collected in the subsequent crushing together with the primary juice.

[0108] Sugarcane juice prepared by any other extraction method is suitable for and can be used in the present disclosure.

[0109] Preparation of enzyme blend:

[0110] The method of preparing an enzyme blend broadly includes the following steps:

[0111] 1. Analyze individual enzyme samples to confirm activity

[0112] 2. W...

Embodiment 2

[0126] Steps to obtain laboratory-scale sulfur-free sugar cane juice / sugar juice:

[0127] a) Use enzyme blend composition ‘A’:

[0128] Put 100ml of sugar cane juice / sugar juice in equal parts into two Erlenmeyer flasks. Record the pH of the initial juice. About 30ppm of enzyme blend'A' (which includes 50% w / w xylanase (exoxylanase or endoxylanase) and 50% w / w cellulase ( Exocellulase or cellobiohydrolase), optionally together with excipients) are added to a flask. Use the other flask as a control. The two flasks were placed in a water bath maintained at 70°C until the temperature of the juice reached about 70°C. Keep the flask at about 70°C for about 10 minutes. After about 10 minutes, the flask was cooled to about 28°C (ambient temperature) after which the test and control flasks (at pH 7) were neutralized with calcium oxide (lime). After that the flask was stoppered and allowed to stand at 100°C for 45-50 minutes. After that, the flask was cooled and the content in it ...

Embodiment 3

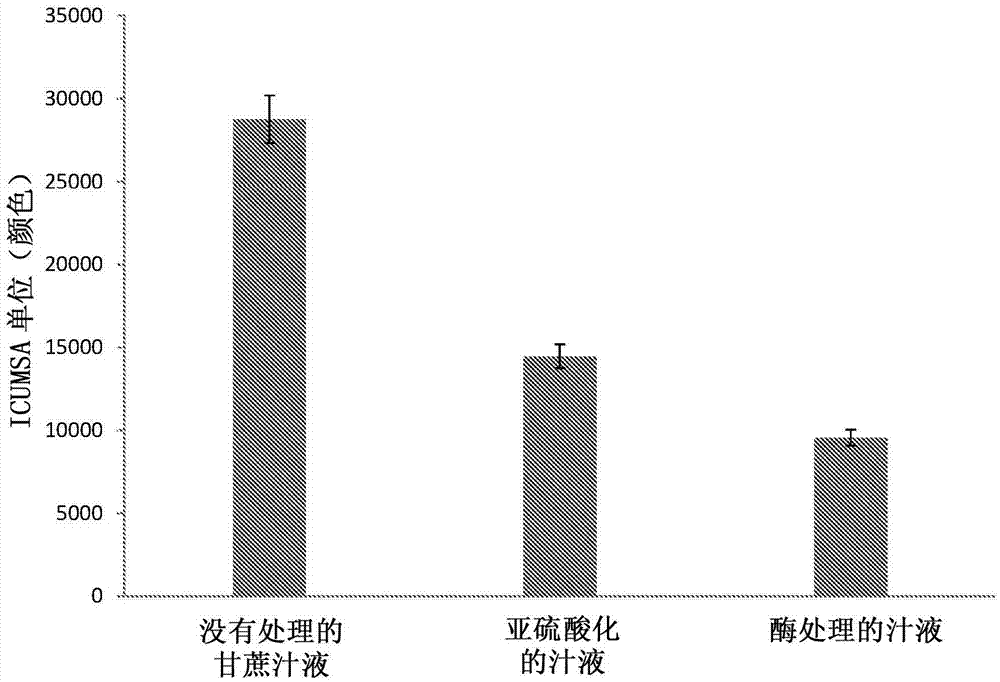

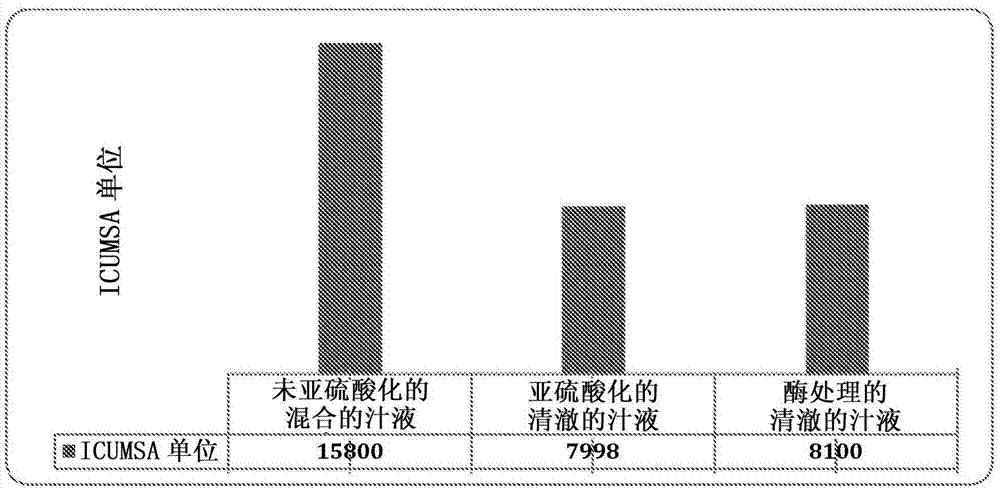

[0142] Steps to evaluate ICUMSA:

[0143] For color analysis, ICUMSA method GS1 / 3-7 is used. The sugarcane juice / sugar juice samples were diluted to obtain Brix of 5.0. Adjust the pH to 7.0 with diluted HCl / NaOH. The sample was filtered through a 0.45 μm membrane and the absorbance was measured at 420 nm for distilled water as a blank.

[0144] Then estimate the color according to the following formula:

[0145] ICUMSA color={absorption rate / (path length of cuvette x cane sugar juice / concentration of sugar juice)}x1000.

[0146] The color of sugar is an indication of the presence of impurities in the sugar. The higher the ICUMSA, the higher the impurities in the sugar and therefore the lower the quality. According to the Codex standard for sugar 212-1999, the limit of ICUMSA for planted or ground sugar is <150.

[0147] (In the laboratory-scale experiment described above, the net treatment with the enzyme blend ‘G’ The result of ICUMSA:

[0148] The preliminary results of this d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com