Additive-free liquid brown sugar and preparation method thereof

A technology without additives and brown sugar, applied in the direction of using physical methods to purify, confectionery, sugar products, etc., can solve the problems of product quality and palatability, difficulty in controlling the preparation method, and low sugar content, so as to avoid product turbidity , stable properties, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

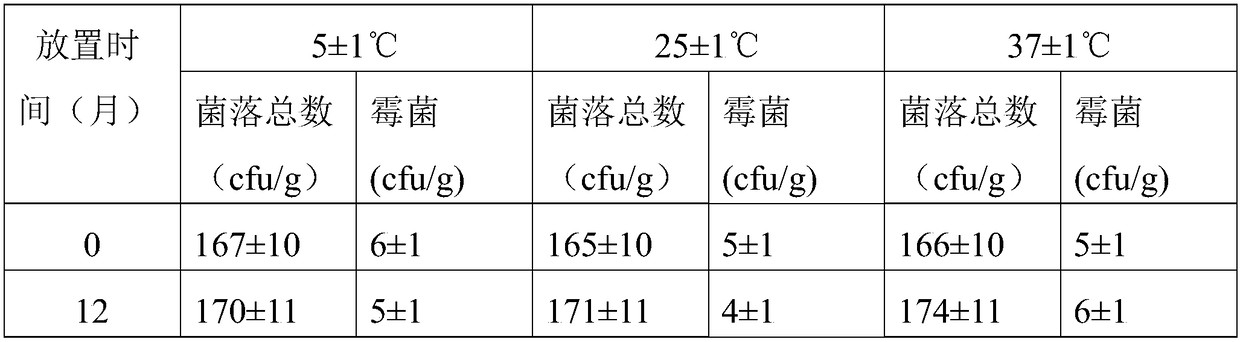

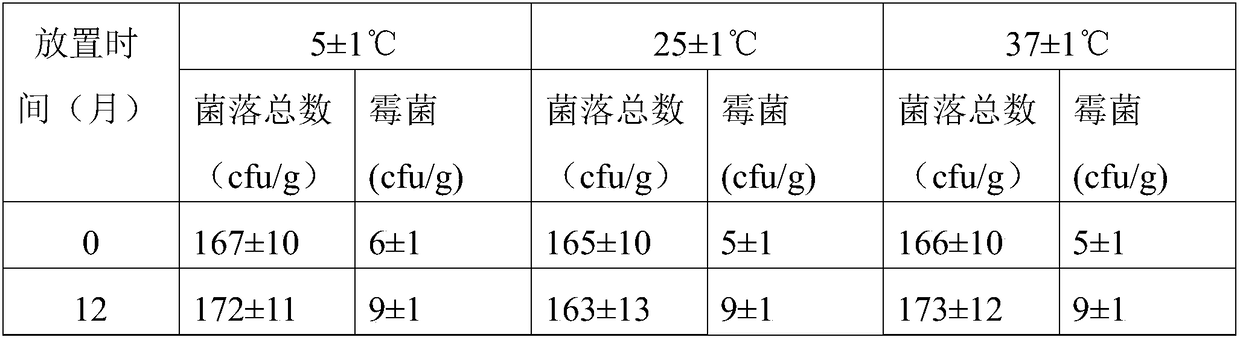

[0041] Select the total number of colonies and mold as microbial detection indicators, and carry out according to the relevant operations of "T / CNFIA 001-2017 General Guidelines for Food Shelf Life"

[0042] Set three temperatures at a relative humidity of 75%: 5°C, 25°C, and 37°C in three incubators, the sample at 5°C is used as a standard sample or control sample, the sample at 25°C is used as a sample on the simulated shelf, and the sample at 37°C The samples are regarded as environmentally destructive samples. Samples at 37°C were evaluated every 5 days, and compared with samples at 5°C. When the sample at 37°C has a large difference or an unacceptable difference from the sample at 5°C, the sample at 37°C should stop the experiment, then multiply the storage time of the sample at 37°C by 3 to get the time This is the approximate shelf life of the product. The samples under the condition of 25°C continue to be tested. When the samples under the condition of 25°C also have...

Embodiment 2

[0046] 1) Weigh 500 kilograms of sugarcane, clean the surface, press with a press to obtain 416 kilograms of sugarcane juice; carry out centrifugal filtration to the sugarcane juice, and obtain 397 kilograms of sugarcane juice for preliminary removal of impurities;

[0047] 2) Get the sugarcane juice centrifugally filtered in (1) to remove impurities by plate and frame filter press to obtain 378 kilograms of sugarcane juice that removes large particles of impurities;

[0048]3) take (2) the sugarcane juice after plate and frame press filtration and filter with 200nm ceramic membrane, obtain 346 kilograms of clarified sugarcane juice;

[0049] 4) Treat 50 kg of clarified sugarcane juice in (3) with immobilized invertase (20,000 U) to obtain an enzymatic hydrolyzate. The treatment conditions are as follows: the amount of immobilized invertase is 0.5%, the enzymolysis temperature is 50° C., the pH value is the natural pH of sugarcane juice, and the enzymolysis time is 300 minutes...

Embodiment 3

[0058] 1) Squeezing: cleaning the surface of sugarcane and pressing to obtain sugarcane juice;

[0059] 2) Filtration: filter the sugarcane juice obtained in step (1), first perform centrifugal filtration, the speed is 1000r / min, and initially remove impurities; The filter cloth has a pore size of 100 mesh to remove large particles of impurities; finally, filter with a 50nm ceramic membrane to obtain clarified sugarcane juice for later use;

[0060] 3) Enzymolysis: use immobilized invertase (20,000 U) to treat the clarified sugarcane juice obtained in step (2), the treatment conditions are: the amount of immobilized invertase is 0.3%, the enzymolysis temperature is 45°C, and the pH value is sugarcane juice Natural pH, the enzymolysis time is 300 minutes, after the enzymolysis is completed, the immobilized invertase is removed by centrifugal filtration, and the clarified enzymolysis solution is obtained;

[0061] 4) Concentration: Concentrate the above-mentioned enzymolysis so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Total number of colonies | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com