High-efficiency composite clarifying agent used for clarification and decolorization of sugar liquid

A compound clarifier and decolorization technology, applied in the production of sugar, purification of sugar juice, purification using adsorbents, etc., can solve the problems of strong technology, high cost, difficult to widely use, etc., to increase the specific surface area and improve the adsorption capacity. Ability, good decolorization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

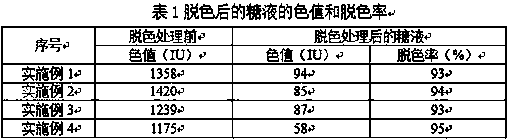

Examples

Embodiment 1

[0022] A high-efficiency composite clarifying agent for clarifying and decolorizing sugar liquid, which consists of the following components in parts by weight: 150 parts of modified calcium phosphate, 5 parts of polyphenol oxidase, and 5 parts of pectinase.

[0023] The preparation method of described modified calcium phosphate, comprises the following steps:

[0024] (1) Mix microcrystalline cellulose and deionized water in a weight ratio of 4:100 to obtain a suspension;

[0025] (2) Add calcium chloride to the suspension obtained in step (1), set the volume to make the calcium ion concentration in the suspension reach 0.6mol / L, and stir thoroughly for 75 minutes to obtain a mixed solution;

[0026] (3) Add dropwise an equal volume of potassium dihydrogen phosphate solution with a molar concentration of 0.5 mol / L to the mixed solution obtained in step (2), stir for 45 minutes after the addition is completed, then let stand for 2 hours, and then Dry at ℃ until it does not fl...

Embodiment 2

[0031] A high-efficiency composite clarifying agent for clarifying and decolorizing sugar liquid, which consists of the following components in parts by weight: 200 parts of modified calcium phosphate, 3 parts of polyphenol oxidase, and 4 parts of pectinase.

[0032] The preparation method of described modified calcium phosphate, comprises the following steps:

[0033] (1) Mix microcrystalline cellulose and deionized water in a weight ratio of 3:100 to obtain a suspension;

[0034] (2) Add calcium chloride to the suspension obtained in step (1), set the volume to make the calcium ion concentration in the suspension reach 0.4mol / L, and stir thoroughly for 65 minutes to obtain a mixed solution;

[0035] (3) Add dropwise an equal volume of potassium dihydrogen phosphate solution with a molar concentration of 0.8mol / L to the mixed solution obtained in step (2), stir for 50 minutes after the dropwise addition is completed, then let stand for 3 hours, and then Dry at ℃ until it doe...

Embodiment 3

[0040] A high-efficiency composite clarifying agent for clarifying and decolorizing sugar liquid, which consists of the following components in parts by weight: 100 parts of modified calcium phosphate, 2 parts of polyphenol oxidase, and 3 parts of pectinase.

[0041] The preparation method of described modified calcium phosphate, comprises the following steps:

[0042] (1) Mix microcrystalline cellulose and deionized water in a weight ratio of 1:100 to obtain a suspension;

[0043] (2) Add calcium chloride to the suspension obtained in step (1), set the volume to make the calcium ion concentration in the suspension reach 0.1mol / L, and stir thoroughly for 90 minutes to obtain a mixed solution;

[0044] (3) Add dropwise an equal volume of potassium dihydrogen phosphate solution with a molar concentration of 0.1 mol / L to the mixed solution obtained in step (2), stir for 30 minutes after the addition is completed, and then let stand for 1 hour, then set aside at 140 Dry at ℃ unti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com