Method and device for refining sugar

A sugarcane juice and container technology, applied in the field of sugar making method and its device, can solve the problems of direct consumption, hard and astringent taste, hard taste, etc., and achieve the effect of increased hydrophilicity of crystals, low degree of adhesion, and soft taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to provide an effective implementation solution, the present invention provides the following embodiments, which will be described below in conjunction with the accompanying drawings.

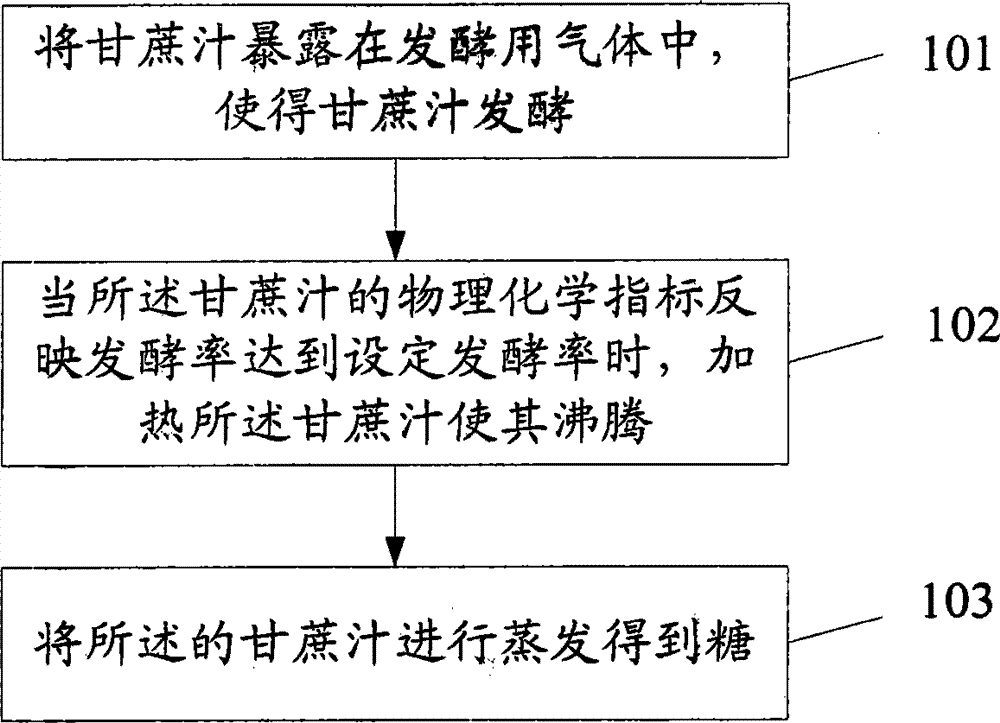

[0036] The present invention firstly provides a sugar making method, comprising such as figure 1 Steps shown:

[0037] Step 101: exposing the sugarcane juice to fermentation gas to ferment the sugarcane juice;

[0038] Step 102: When the physical and chemical indicators of the sugarcane juice reflect that the fermentation rate reaches the set fermentation rate, heating the sugarcane juice to make it boil;

[0039] Step 103: Evaporating the sugarcane juice to obtain sugar;

[0040] The set fermentation rate is greater than 0.

[0041] Different from the method of directly evaporating sugarcane juice to produce sugar in the traditional process, the method of sugar production provided by the present invention firstly ferments the sugarcane juice, and then evaporates the sugarcan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com