Biological treatment method for sulfur-free sugarcane juice clarification

A technology for biological treatment and cane juice, which is applied in the direction of purification using physical methods, sucrose production, and sugar production. risk, reduction in processing difficulty, and the effect of reducing impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

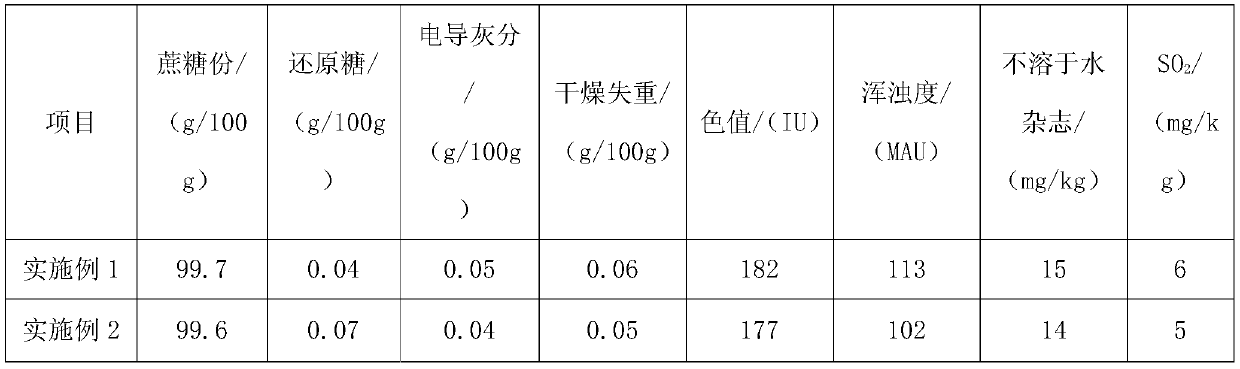

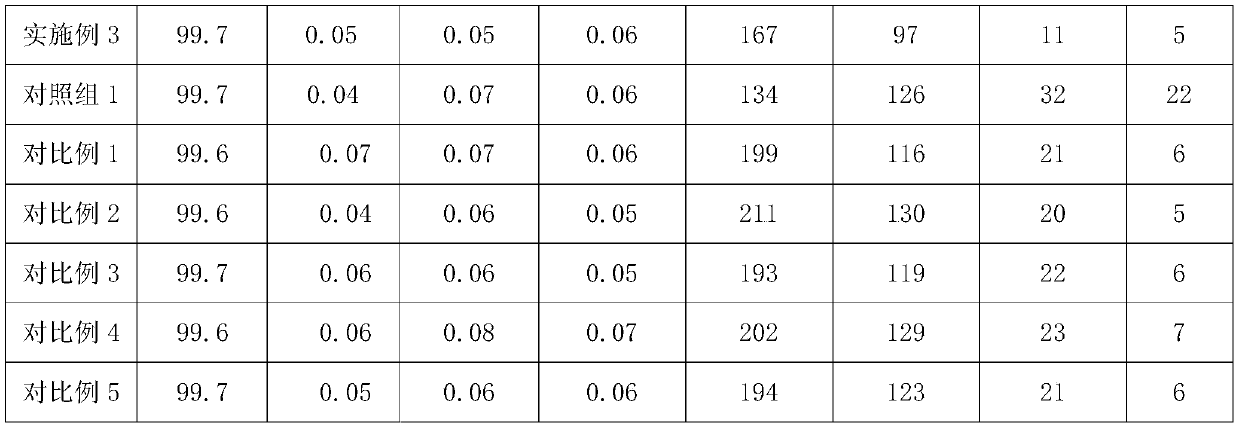

Examples

Embodiment 1

[0031] A biological treatment method for clarification of sulfur-free cane juice, specifically comprising the following steps:

[0032] (1) Sugarcane pressing: arrange the sugarcane for impurity removal, and obtain mixed juice after 3 times of pressing;

[0033] (2) Coarse filtration treatment: the mixed juice made in step (1) is filtered to remove bagasse to obtain sugarcane juice;

[0034] (3) adjustment: the cane juice made by step (2) is carried out inter-oxygen aeration in the aeration tank, and the reaction time is 20 minutes at 35° C., then adding phosphoric acid 35ppm and weight are 0.05% modified sugarcane juice The modified bentonite is used to absorb pigments and trap tiny colloidal impurities; the modified bentonite is prepared by the following method: pour the bentonite into water for sedimentation, for 3 consecutive times, each time take the upper suspension, and carry out the process at 1000 rpm Centrifuge, centrifuge for 20S, dry; add olive oil and vitamin C t...

Embodiment 2

[0040] A biological treatment method for clarification of sulfur-free cane juice, specifically comprising the following steps:

[0041] (1) Sugarcane pressing: arrange the sugarcane for impurity removal, and obtain mixed juice after 5 times of pressing;

[0042] (2) Coarse filtration treatment: the mixed juice made in step (1) is filtered to remove bagasse to obtain sugarcane juice;

[0043] (3) adjustment: the sugarcane juice made by step (2) is carried out inter-oxygen aeration in the aeration tank, and the reaction time is 30 minutes at 40°C, and then adding phosphoric acid 75ppm and weight is 0.08% modified sugarcane juice The modified bentonite is used to absorb pigments and trap tiny colloidal impurities; the modified bentonite is prepared by the following method: pour the bentonite into water for sedimentation, 5 times in a row, take the upper layer suspension each time, and carry out the process at 1500 rpm Centrifuge, centrifuge for 30S, dry; add olive oil and vitami...

Embodiment 3

[0049] A biological treatment method for clarification of sulfur-free cane juice, specifically comprising the following steps:

[0050] (1) Sugarcane pressing: arrange the sugarcane for impurity removal, and obtain mixed juice after 4 times of pressing;

[0051] (2) Coarse filtration treatment: the mixed juice made in step (1) is filtered to remove bagasse to obtain sugarcane juice;

[0052] (3) adjustment: the sugarcane juice made by step (2) is carried out inter-oxygen aeration in the aeration tank, and the reaction time is 25 minutes at 38° C., and then adding phosphoric acid 55 ppm and weight are modified sugarcane juice 0.06%. The modified bentonite can absorb pigments and collect tiny colloidal impurities; the modified bentonite is prepared by the following method: pour the bentonite into water for sedimentation, 4 times in a row, take the upper layer suspension each time, and carry out the process at 1200 rpm Centrifuge, centrifuge for 28S, dry; add olive oil and vitam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com