MEMS device, preparation method and electronic apparatus

A technology of electronic devices and devices, which is applied in the field of MEMS devices and their preparation, can solve problems such as device preparation difficulties, and achieve the effect of strong implementability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

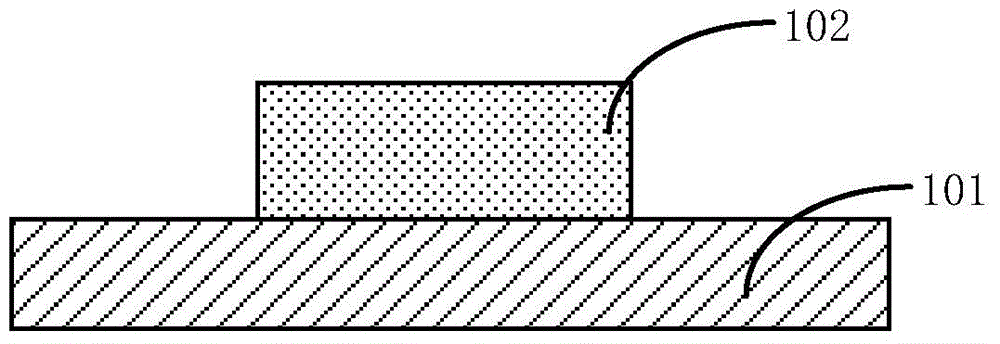

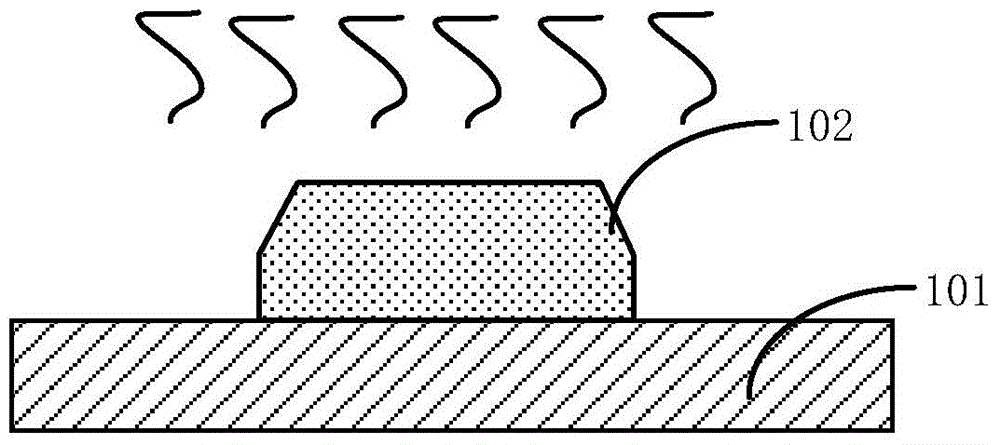

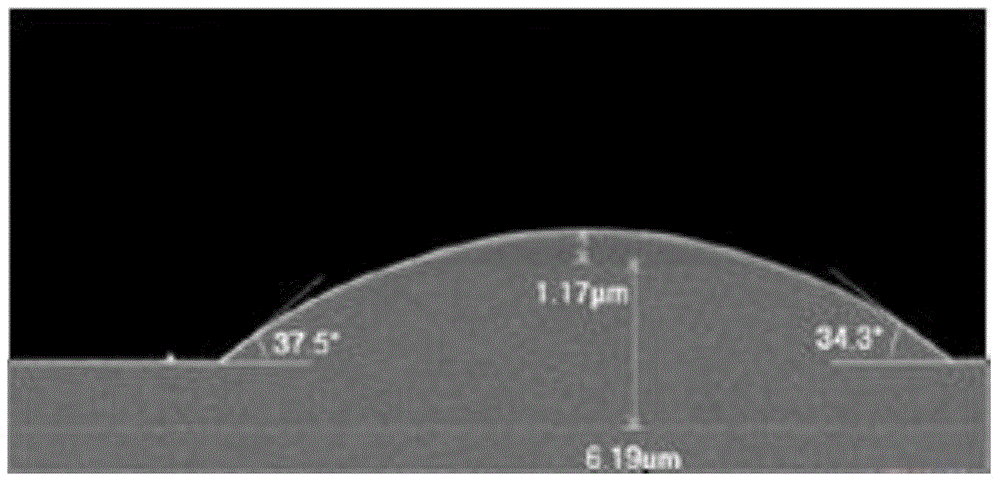

[0039] Arc-shaped steps are often used in the preparation process of MEMS devices, such as Figure 1c shown. Usually, the following two methods are used to change the pattern morphology after photolithography:

[0040] The first method is photoresist reflow: the commonly used arc-shaped step forming method is to provide a MEMS wafer 101, form a photoresist 102 on the MEMS wafer 101, and form a square or trapezoid on the photoresist graphics, such as Figure 1a As shown, the thermoplastic heating of the photoresist is then used to reflow the photoresist to form a circular arc shape, as shown in Figure 1bshown. Finally, through an etching process, the photoresist pattern is transferred to other materials. This method utilizes the thermoplasticity of the photoresist to heat the photoresist to the melting temperature, so that the photoresist naturally shrinks to form an arc-shaped shape. The disadvantage of this method is that the process of forming an arc-shaped shape is unco...

Embodiment 1

[0044] In order to solve the problems existing in the prior art, the present invention provides a kind of preparation method of MEMS device, below in conjunction with attached Figure 2a-2f The method is described further.

[0045] First, step 201 is performed to provide a MEMS wafer 201 on which a first photoresist layer 202 is formed.

[0046] Specifically, such as Figure 2a As shown, the MEMS wafer 201 can be made of semiconductor materials such as silicon, polysilicon or SiGe, and is not limited to a certain one.

[0047] The MEMS device formed in the present invention may be a sensor, such as a pressure sensor, an acceleration sensor, etc., or a MEMS microphone, or other types of MEMS devices, and is not limited to a certain one.

[0048] Wherein, the first photoresist layer 202 is a photoresist sensitive to a specific wavelength, for example, the first photoresist layer 202 is sensitive to a light source with a first wavelength.

[0049] Further, the wavelength of th...

Embodiment 2

[0086] The present invention also provides a MEMS device, the MEMS device is prepared by the method described in Example 1, the shape of the arc-shaped step in the MEMS device is more controllable, and more in line with the requirements of the design pattern The method solves the problem of uncontrollable arc-shaped steps in the prior art, and further improves the performance and yield of MEMS devices.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com