Gypsum product drainage defrosting agent and preparation method thereof

A defrosting agent and product technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of not fundamentally solving the problem of frosting, the effect is not obvious, etc., to reduce the drying time, Good drainage and defrosting effect, obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

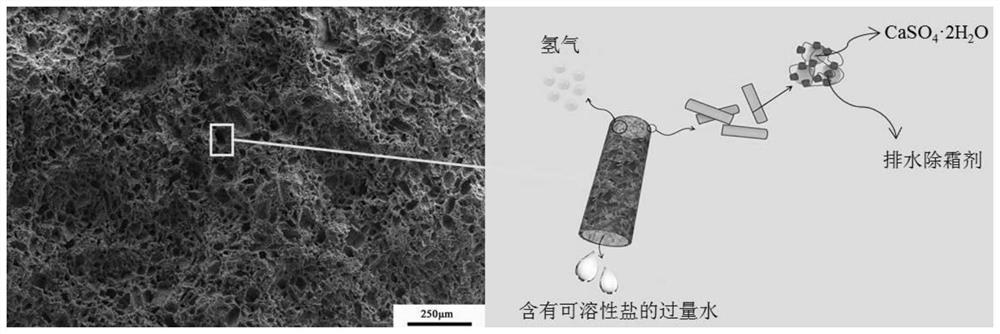

Method used

Image

Examples

Embodiment 1

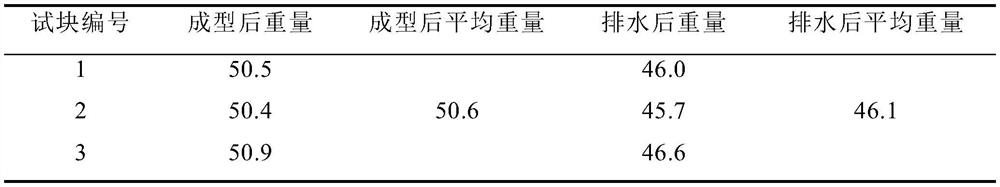

[0033] Parts by weight are 10,000 parts of building gypsum powder, 10,000 parts of water, 3 parts of hydrogen-containing silicone oil, 6 parts of dimethyl silicone oil, 6 parts of 1,1,3,3-tetramethyldisiloxane, 1,1,5, 30 parts of 5-tetramethyl-3,3-diphenyltrisiloxane, 18 parts of dimethyl hydroxy silicone oil, 12 parts of hydrogen-terminated phenyl silicone oil, 18 parts of hydrogen-terminated polydimethylsiloxane, Molded in the factory mold, formed into 666mm × 500mm × 120mm test block, formed 18 pieces, randomly selected 3 pieces and weighed each piece to calculate the average weight, and weighed after draining. The specific data is shown in Table 1.

[0034] Table 1 Mass of the sample before and after drainage

[0035]

[0036] From the data in Table 1, it can be seen that about 8.89% of water can be discharged.

Embodiment 2

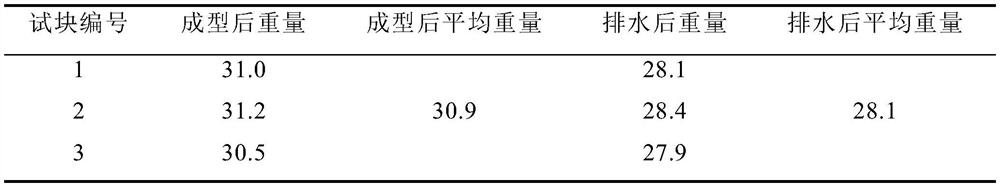

[0038] Parts by weight are 10,000 parts of building gypsum powder, 10,000 parts of water, 3 parts of hydrogen-containing silicone oil, 6 parts of dimethyl silicone oil, 6 parts of 1,1,3,3-tetramethyldisiloxane, 1,1,5, 30 parts of 5-tetramethyl-3,3-diphenyltrisiloxane, 18 parts of dimethyl hydroxy silicone oil, 12 parts of hydrogen-terminated phenyl silicone oil, 18 parts of hydrogen-terminated polydimethylsiloxane, Molded in the factory mold, formed into 500mm × 247mm × 200mm test block, formed 24 pieces, randomly selected 3 pieces and weighed each piece to calculate the average weight, and weighed after draining. The specific data is shown in Table 2.

[0039] Table 2 Mass of the sample before and after drainage

[0040]

[0041] It can be seen from the data in Table 2 that about 9.06% of water can be discharged.

Embodiment 3

[0043] Parts by weight are 10,000 parts of building gypsum powder, 10,000 parts of water, 3 parts of hydrogen-containing silicone oil, 6 parts of dimethyl silicone oil, 6 parts of 1,1,3,3-tetramethyldisiloxane, 1,1,5, 30 parts of 5-tetramethyl-3,3-diphenyltrisiloxane, 18 parts of dimethyl hydroxy silicone oil, 12 parts of hydrogen-terminated phenyl silicone oil, 18 parts of hydrogen-terminated polydimethylsiloxane, Molded in the factory mold, formed into 666mm × 500mm × 120mm test block, formed 18 pieces, collected the discharged water, and recorded it as sample A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com