Method for preparing graphene through electrochemical cathodic disbonding graphene sheets by taking DTAB as electrolyte

A cathodic stripping and electrochemical technology, applied in the field of graphene, can solve problems such as multiple preparation procedures, many influencing factors, and complicated preparation process, and achieve important scientific value, wide application prospects, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

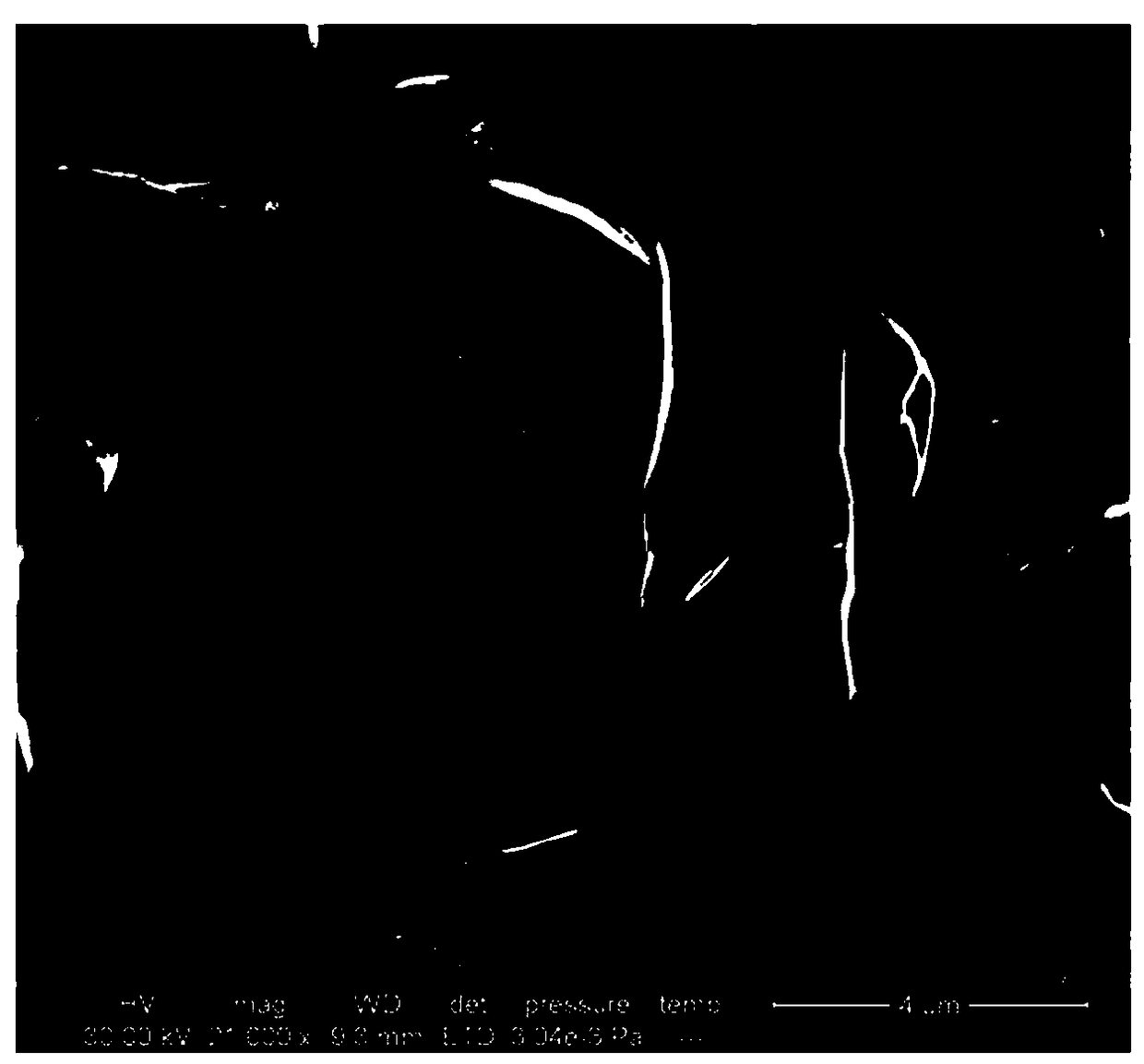

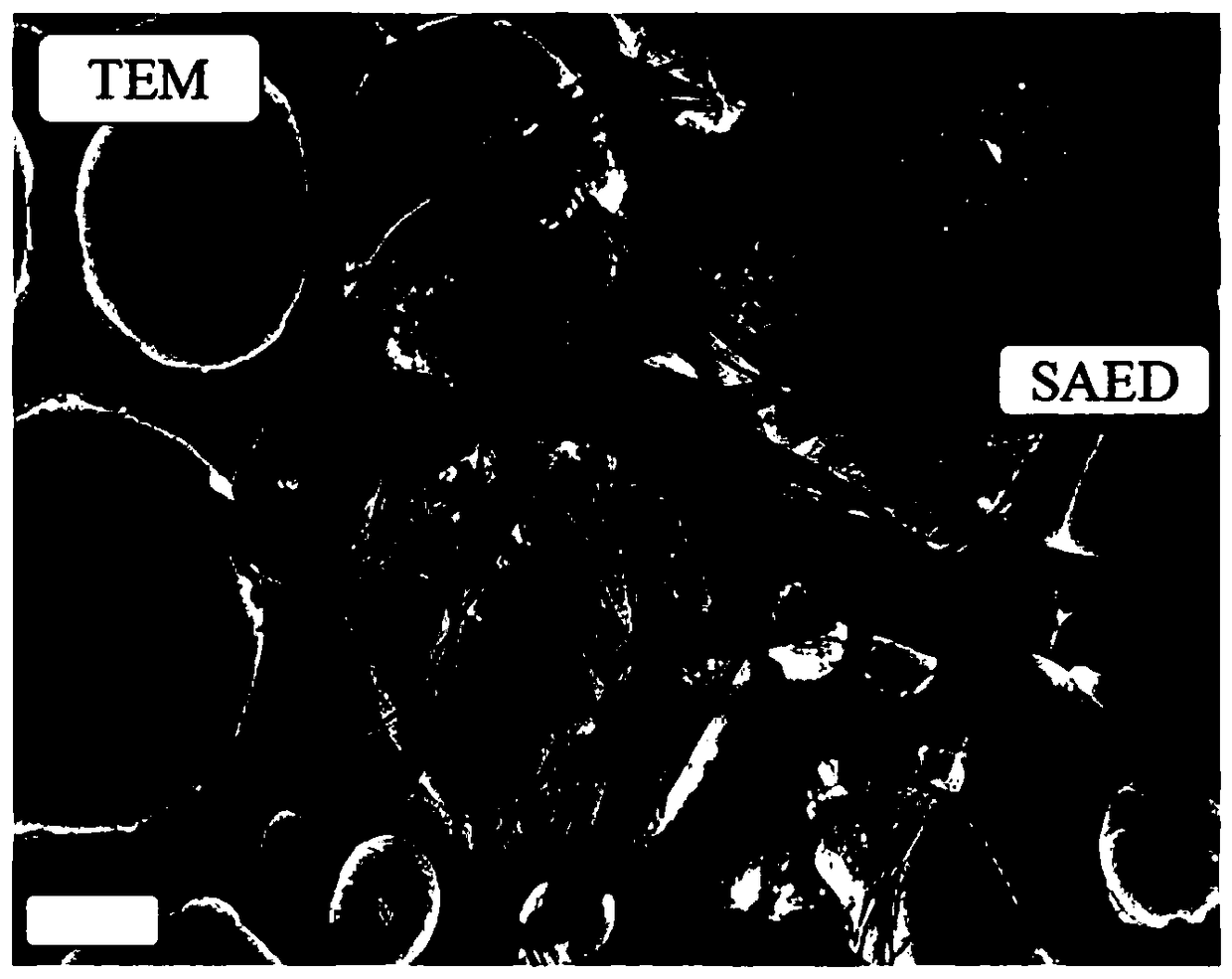

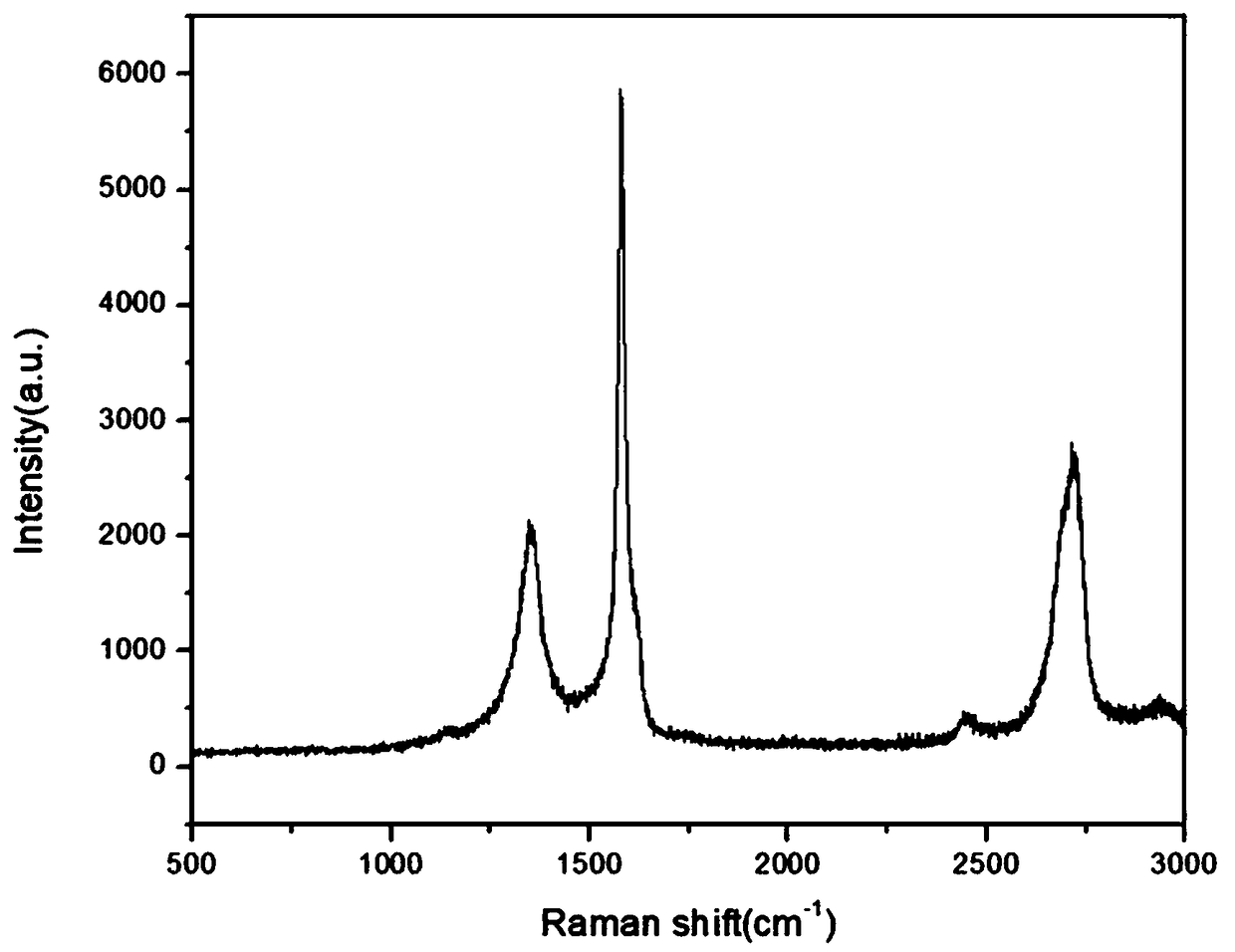

[0037] A kind of method using DTAB as electrolytic cathode stripping graphite foil to prepare graphene comprises the steps:

[0038] 1) Preparation of materials: Prepare graphite electrodes, absolute ethanol, DTAB, DC power supply, iron stand and conductive clips for backup;

[0039] 2) Preparation of electro-stripping solution: Weigh the dehydrated alcohol prepared in step 1), DTAB, and prepare 0.1mol / L DTAB electrochemical stripping graphene electro-stripping solution;

[0040] 3) Assembling the electrostripping device: the graphite electrodes are respectively used as the cathode and the anode, and the two electrodes are vertically and parallelly immersed in the electrostripping liquid, there is a distance between the two electrodes, and the two electrodes are connected to a DC stabilized voltage supply;

[0041] 4) Electrostripping: switch on the power supply voltage and set it to 15V for electrochemical stripping for 120 minutes;

[0042] 5) Filtration and washing: the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com