FeGa magnetostriction alloy wire and preparation method thereof

A magnetostrictive and alloy wire technology, applied in the field of FeGa magnetostrictive alloy wire and its preparation, can solve the problem of low degree of grain alignment of FeGa magnetostrictive materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

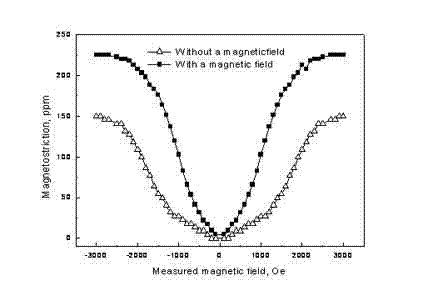

Image

Examples

Embodiment 1

[0026] (1) Using pure Fe with a purity of ≥99.9wt% and Ga with a purity of ≥99.9wt% as raw materials, the as-cast Fe-15%Ga (atomic fraction) was prepared by suction casting in a high-vacuum electric arc furnace under the protection of argon at 0.5 standard atmospheric pressure master alloy;

[0027] (2) Place the prepared as-cast FeGa master alloy in a 0.01T magnetic field, raise the temperature to 1550°C, and keep it for 2 hours, then make the cast FeGa master alloy under the conditions of a temperature gradient of 50°C / mm and a pulling rate of 0.5mm / s. Directional solidification of FeGa master alloy;

[0028] (3) Place the prepared FeGa alloy directionally solidified under a magnetic field in a 20T magnetic field, at a temperature of 1000°C, keep it warm for 12 hours, cool it to 750°C at a cooling rate of 5°C / min, keep it warm for 24 hours, and then Cool to room temperature with the furnace;

[0029] (4) Hot forging the FeGa alloy after magnetic field heat treatment at 700...

Embodiment 2

[0036] (1) Using pure Fe with a purity of ≥99.9wt% and Ga with a purity of ≥99.9wt% as raw materials, the as-cast Fe-27%Ga (atomic fraction) was prepared by suction casting in a high-vacuum electric arc furnace under the protection of argon at 0.75 standard atmospheric pressure master alloy;

[0037] (2) Place the prepared as-cast FeGa master alloy in a 10T magnetic field, raise the temperature to 1450°C, keep it for 1 hour, and make the as-cast Directional solidification of FeGa master alloy;

[0038] (3) Place the prepared FeGa alloy directionally solidified under a magnetic field in a 12T magnetic field, at a temperature of 1050°C, keep it warm for 0.5 hours, cool it to 850°C at a cooling rate of 0.5°C / min, hold it for 0.5 hours, and then Quenching;

[0039] (4) Hot forging the FeGa alloy after magnetic field heat treatment at 720°C with a total area reduction rate of 0.35;

[0040] (5) The hot-forged FeGa alloy is subjected to large plastic deformation at room temperatu...

Embodiment 3

[0046] (1) Using pure Fe with a purity of ≥99.9wt% and Ga with a purity of ≥99.9wt% as raw materials, the cast Fe-30%Ga (atom fraction) master alloy;

[0047] (2) Place the prepared as-cast FeGa master alloy in a 20T magnetic field, raise the temperature to 1400°C, hold it for 0.5 hours, and make the as-cast FeGa Directional solidification of master alloy;

[0048] (3) Place the prepared FeGa alloy directionally solidified under a magnetic field in a 0.01T magnetic field, at a temperature of 1100°C, keep it warm for 24 hours, then cool it to 800°C at a cooling rate of 2°C / min, and hold it for 10 hours. Then quench;

[0049] (4) Hot forging the FeGa alloy after magnetic field heat treatment at 800°C with a total area reduction rate of 0.5;

[0050] (5) The hot-forged FeGa alloy is subjected to large plastic deformation at room temperature with a total area reduction rate of 0.4;

[0051] (6) Place the FeGa material obtained after large plastic deformation in a magnetic fiel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com