Multipurpose pawl pipe wrench

A technology of ratchet and pipe wrench, which is applied in the field of multi-purpose ratchet pipe wrench, which can solve the problems of anti-skid teeth losing the anti-skid function, material cost increase of ratchet wrench, hook-shaped wrench reset, and other problems, achieving reasonable structure and low weight. Lightweight, working fast and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

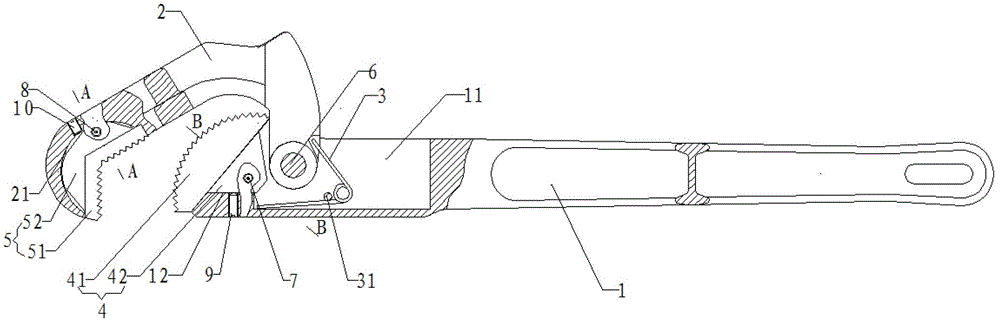

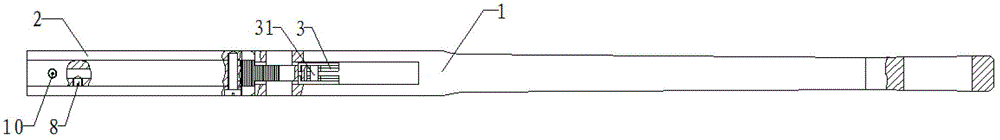

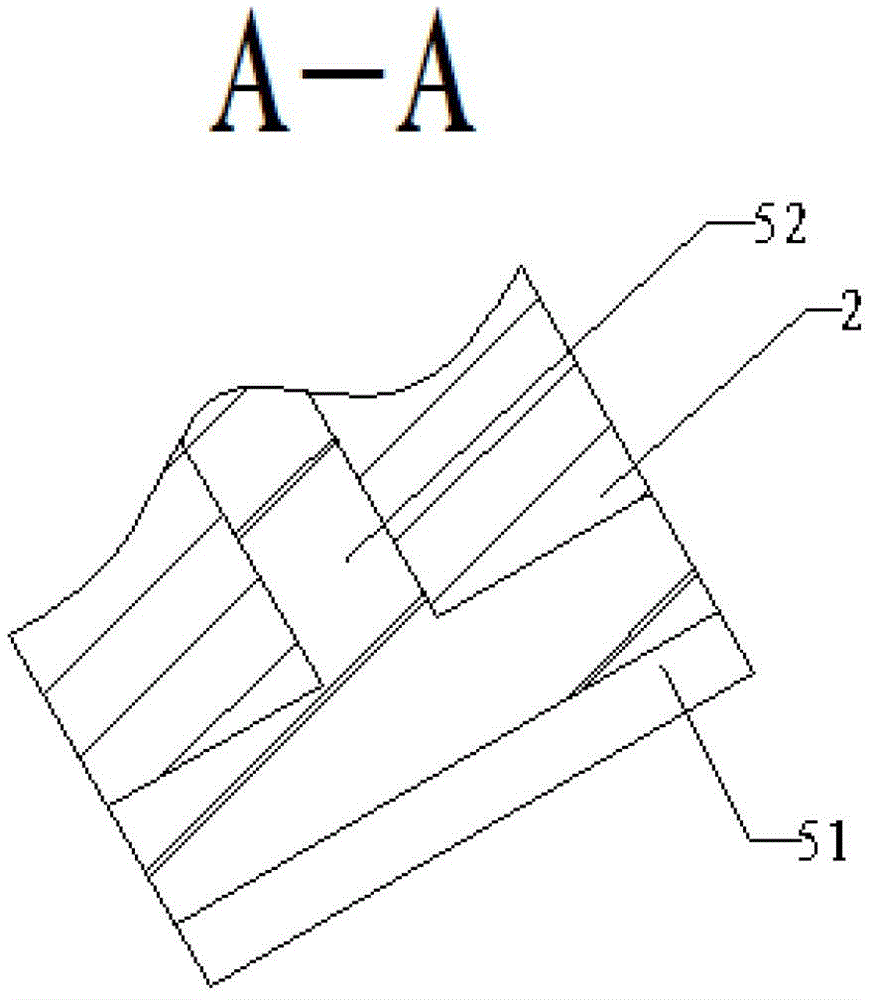

[0034] see figure 1 To attach Figure 4 , as shown in the accompanying drawings, a multi-purpose ratchet pipe wrench provided by the present invention includes a handle body 1, a pin shaft 6, an upper jaw clip 2 and a torsion spring 3, and the upper jaw clip 2 is hinged on the handle body 1 through a pin shaft 6, The handle body 1 is provided with an assembly groove 11, the torsion spring 3 is arranged in the assembly groove 11, a driving end of the torsion spring 3 is arranged on the upper jaw 2, and the other end of the torsion spring 3 is arranged on the assembly groove, The multi-purpose ratchet pipe wrench also includes an arc-shaped tooth surface insert 4 and an upper tooth surface insert 5. The arc-shaped tooth surface insert 4 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com