Pipe wrench

A pipe wrench and movable clamp technology, applied in the direction of wrenches, wrenches, screwdrivers, etc., can solve the problems of reducing the friction force of the bite point, affecting the effect of the pipe wrench on the clamped object, and slipping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

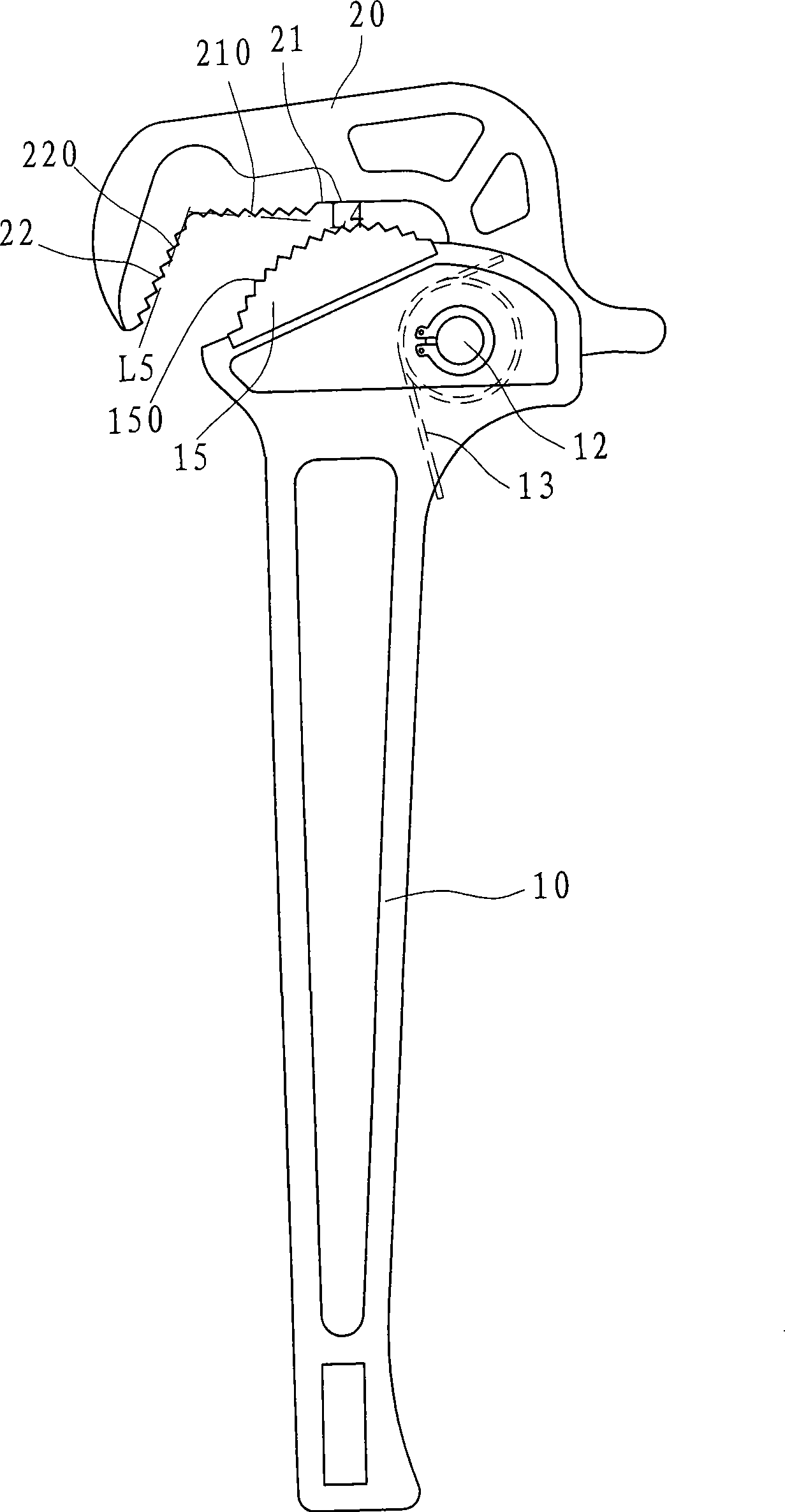

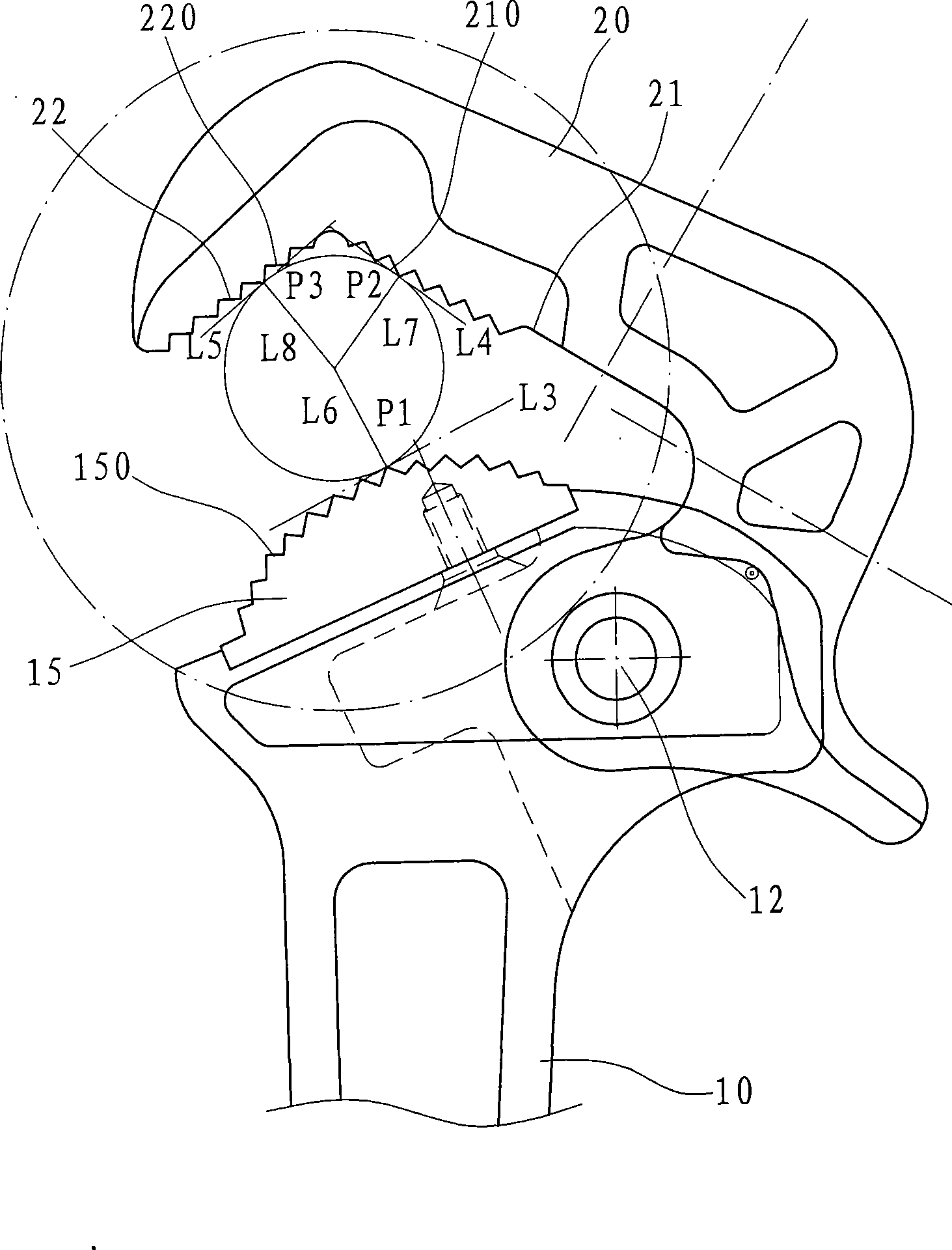

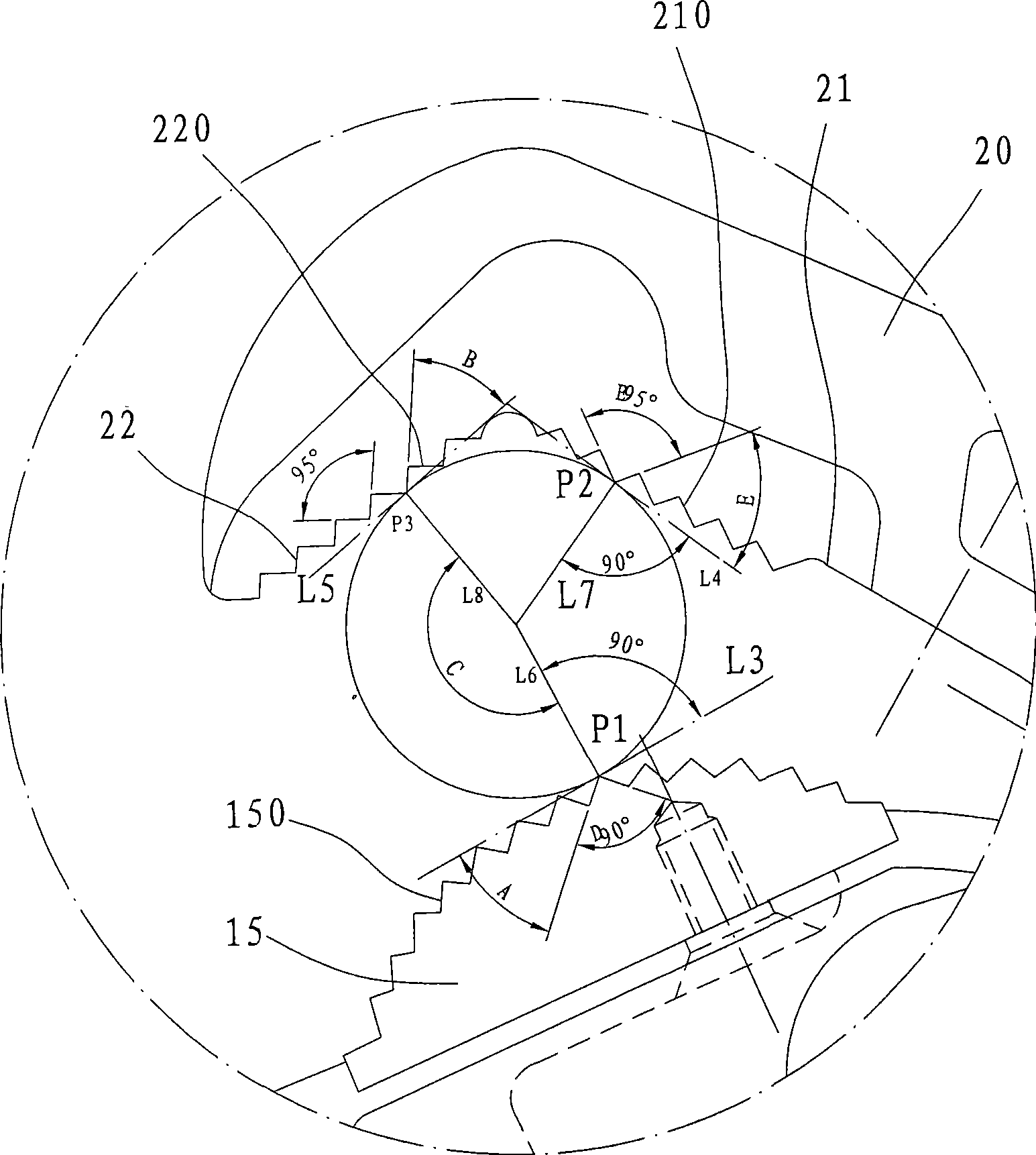

[0024] The invention relates to a pipe wrench for clamping objects such as round pipes or rods, such as figure 1 As shown, the pipe wrench structure of the present invention has a long rod-shaped handle 10, at least one of the two ends of the handle 10 is pivoted with a movable jaw 20 by a pivot 12, and the handle 10 corresponds to the end lock of the opening of the movable jaw 20. An arc-shaped jaw block 15 is provided;

[0025] And about the detailed description of the characteristic step of the present invention, then please refer to simultaneously figure 1 , figure 2 , image 3 As shown, the structure of the pipe wrench is provided with a torsion spring 13 on the pivot 12 between the movable jaw 20 and the handle 10, and the protruding feet at both ends of the torsion spring 13 are supported on the opposite inner surfaces of the handle 10 and the movable jaw 20 respectively. , so that the movable jaw 20 can be automatically occluded relative to the arc-shaped jaw block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com