Electric pipe wrench for threaded connection of reinforcing steel bar and connecting sleeve

A technology of steel connecting sleeve and threaded connection, applied in the direction of wrenches, wrenches, manufacturing tools, etc., can solve the problems of low work efficiency, leaking or inaccurate tightening torque, waste of time, etc. Adjustment and operation are safe and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

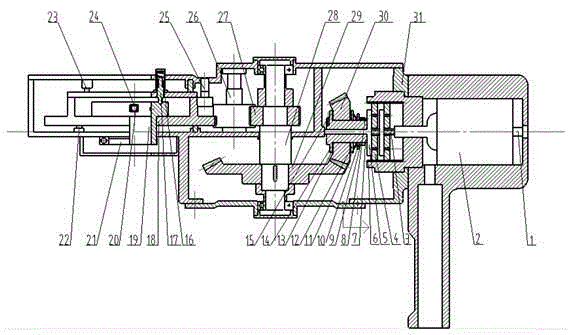

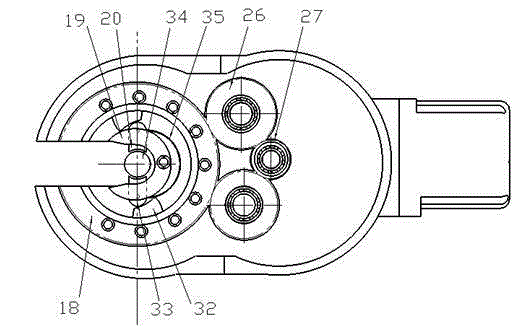

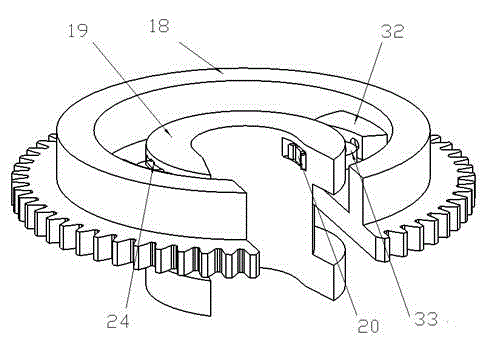

[0016] The present invention is made up of shell 31, power device, transmission device, torque device, return device, rotating connection device.

[0017] As shown in the figure, the lower part of the shell 31 is a handle, and the power device, the transmission device, the torque device, the return device and the rotating connection device are sequentially installed in the shell 31 along the length direction of the shell 31 .

[0018] The figure shows that the power device is composed of rotor 1, stator 2, etc., with a rated voltage of 220v, a power of 620w, and a speed of 20r / min under rated load. . The stator 2 is fixed at the rear end of the casing 31, the rotor 1 is embedded in the middle of the stator 2, and the rotating shaft of the rotor 1 is connected with the transmission device.

[0019] Show among the figure, transmission device is made up of reduction mechanism and small bevel gear 30, large bevel gear 29, large bevel gear shaft 28, axle gear 27. The rotating sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com