Rubber composition for tread and pneumatic tire

A rubber composition and tread technology, applied in special tires, tire parts, transportation and packaging, etc., can solve problems such as insufficient driving performance on dry roads, achieve excellent handling stability, excellent wet grip performance, and improve durability. abrasive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 5

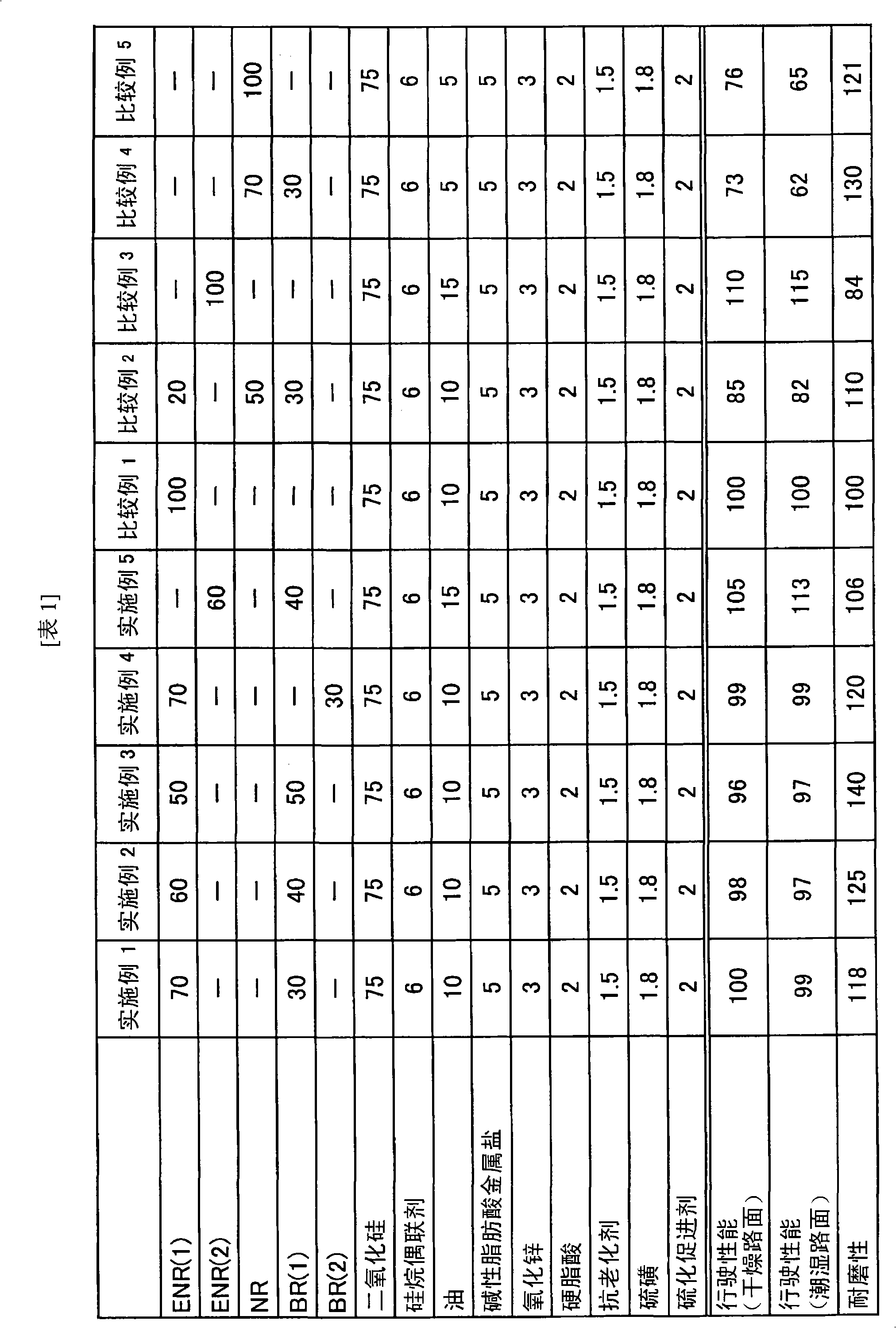

[0085] Examples 1 to 5, and Comparative Examples 1 to 5

[0086] According to each formulation shown in Table 1, components other than sulfur and a vulcanization accelerator were mixed and kneaded at a temperature of 130° C. for 5 minutes using a 1.7 L Banbury mixer to provide a kneaded mass. Sulfur and a vulcanization accelerator were added to the resulting kneaded mass, and they were kneaded by an open mill at a temperature of 60° C. for 3 minutes to produce an unvulcanized rubber composition. The resulting unvulcanized rubber composition was molded into a tread shape, assembled with other tire components, and then vulcanized at a temperature of 150°C for 30 minutes. As a result, test tires (tire size: 195 / 65R 15) were produced.

[0087] The obtained test tires were subjected to the following evaluations. The test results are shown in Table 1.

[0088] (braking test)

[0089] The obtained test tire was mounted on a domestic FR car of 2000 cc displacement. On a dry aspha...

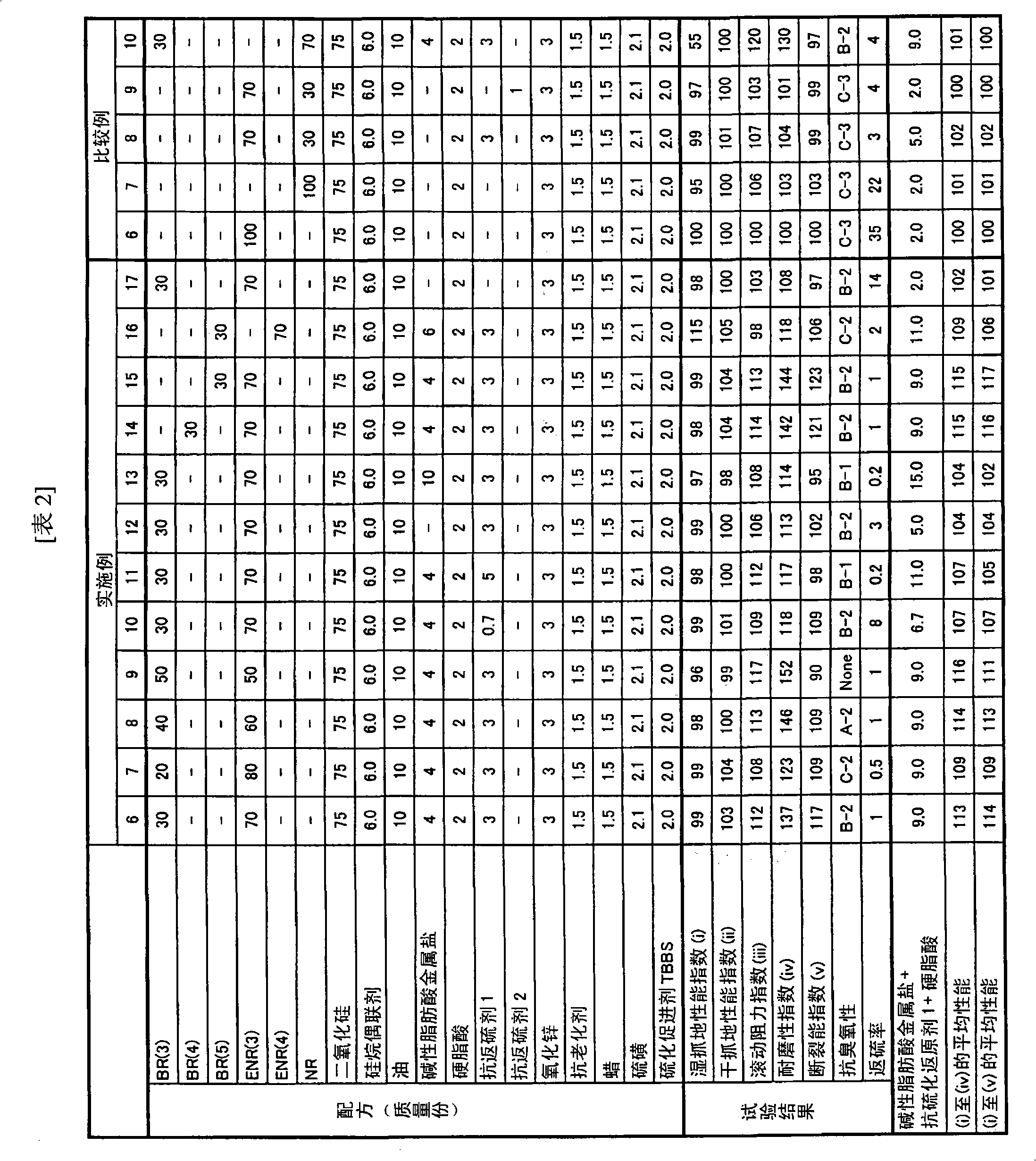

Embodiment 6 to 17 and comparative example 6 to 10

[0115] According to each formulation shown in Table 2, components other than sulfur and a vulcanization accelerator were mixed and kneaded for 5 minutes using a 1.7 L Banbury mixer to raise the outlet temperature to 150° C., thereby obtaining a kneaded mass. Sulfur and a vulcanization accelerator were added to the resulting kneaded mass, and then they were kneaded by an open two-roll mill at a temperature of 80° C. for 3 minutes to produce an unvulcanized rubber composition.

[0116] The resulting unvulcanized rubber composition was press vulcanized at 170° C. for 15 minutes to provide a vulcanized rubber composition.

[0117] The resulting unvulcanized rubber composition was molded into a tread shape, assembled with other tire components, and then vulcanized at a temperature of 170° C. for 15 minutes to produce a test tire.

[0118] The resulting unvulcanized rubber composition, vulcanized rubber sheet, and test tire were subjected to the following evaluations. The test resu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com