Four-season all-steel ice and snow tire tread rubber composition

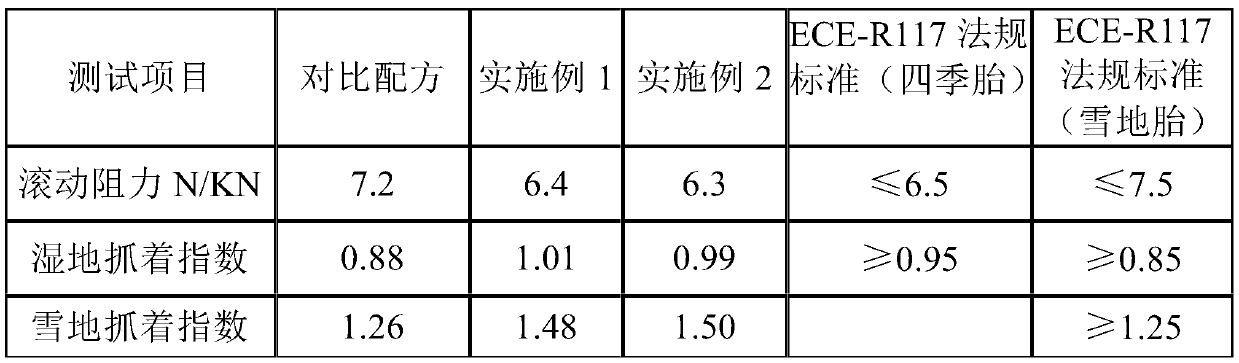

A technology of rubber composition and tire tread, which is applied in the field of tire rubber, can solve the problem of heavy load of all-steel tires, reduced tire wear resistance and rolling resistance performance, and no report on snow tread wear resistance and rolling resistance Performance and other issues, to achieve the effect of excellent rolling resistance performance, excellent low temperature resistance, excellent cold resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

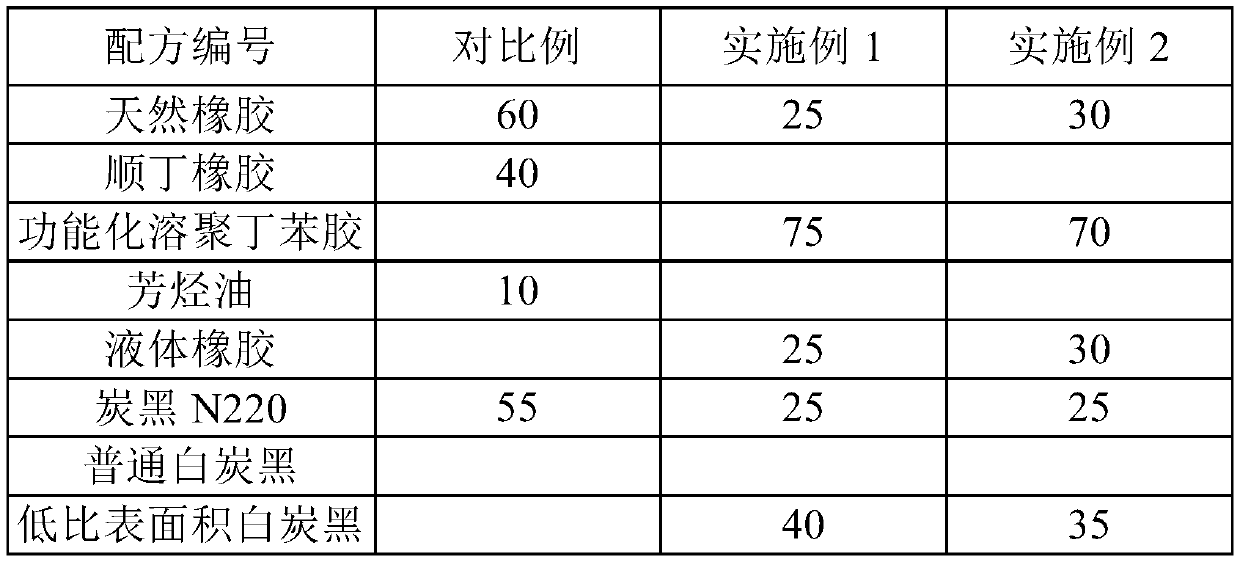

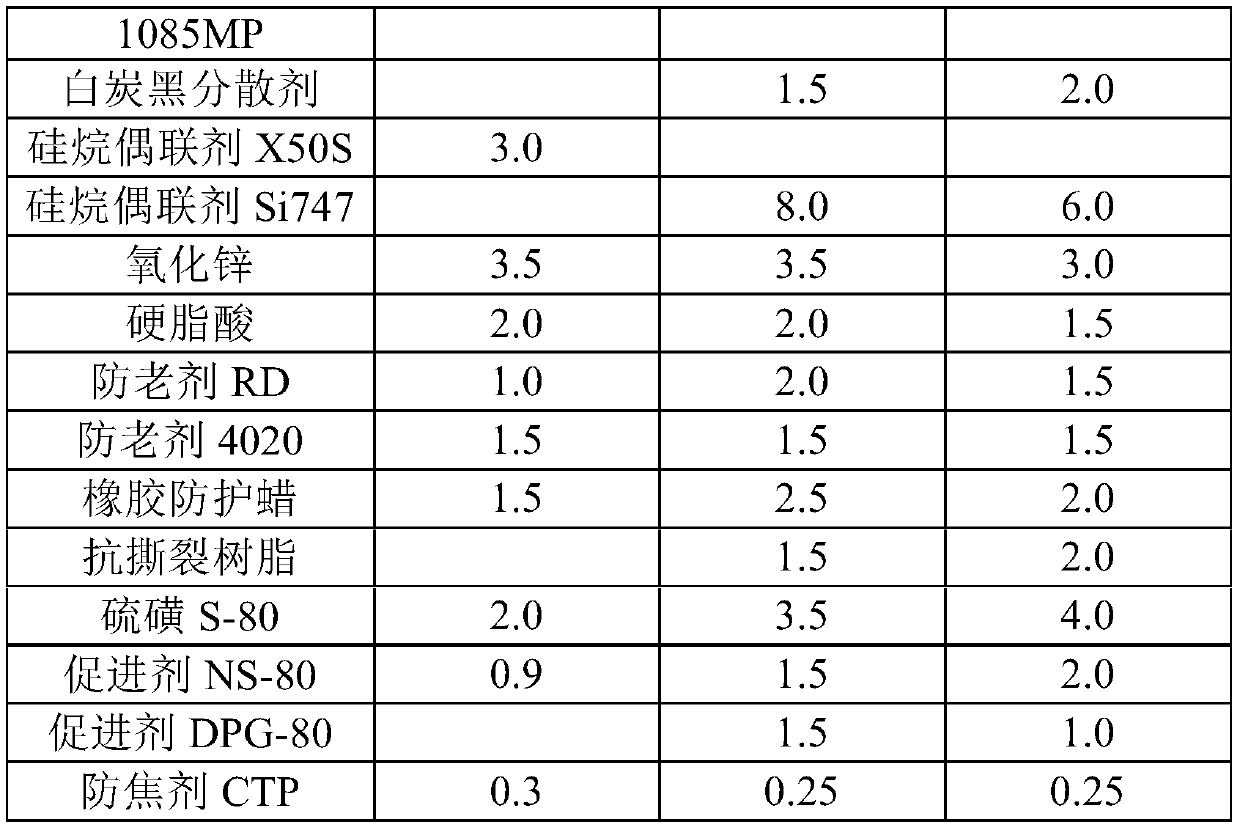

[0016] The present invention will be further described below in conjunction with the embodiments. Apparently, the described embodiments are only some embodiments of the present invention, rather than all embodiments.

[0017] The functionalized solution-polymerized styrene-butadiene rubber is non-oil-extended end-modified solution-polymerized styrene-butadiene rubber with a glass transition temperature lower than -60°C, with a bound styrene content between 5-10%, 1,2- The vinyl content is 15-30%, and it is SL553R produced by JSR in Japan; the ratio of the number of solution-polymerized styrene-butadiene rubber to the number of natural rubber is greater than or equal to 2:1 and less than or equal to 3:1.

[0018] The liquid rubber is liquid butadiene rubber, liquid natural rubber or liquid isoprene rubber with a number average molecular weight of <3000g / mol, and the ratio of the liquid rubber parts to the natural rubber parts is greater than or equal to 1:1 Less than or equal t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com