Low-temperature-resistant wet-skid-resistant tire tread and preparation method thereof

A tire tread and anti-wet skid technology, which is applied to special tires, tire parts, rolling resistance optimization, etc., can solve the problems of not being able to better improve wet skid resistance and low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

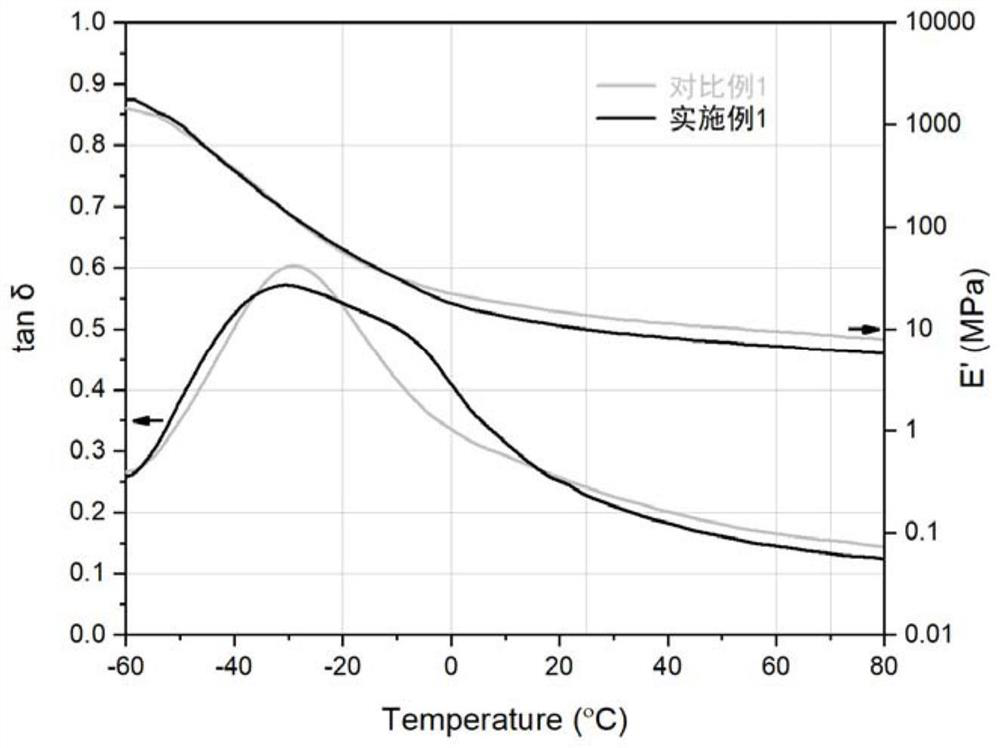

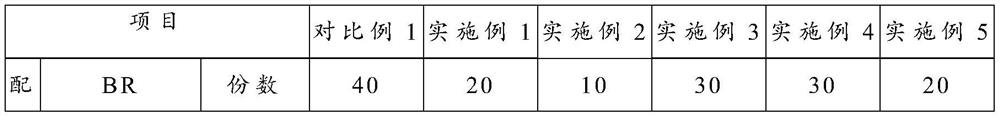

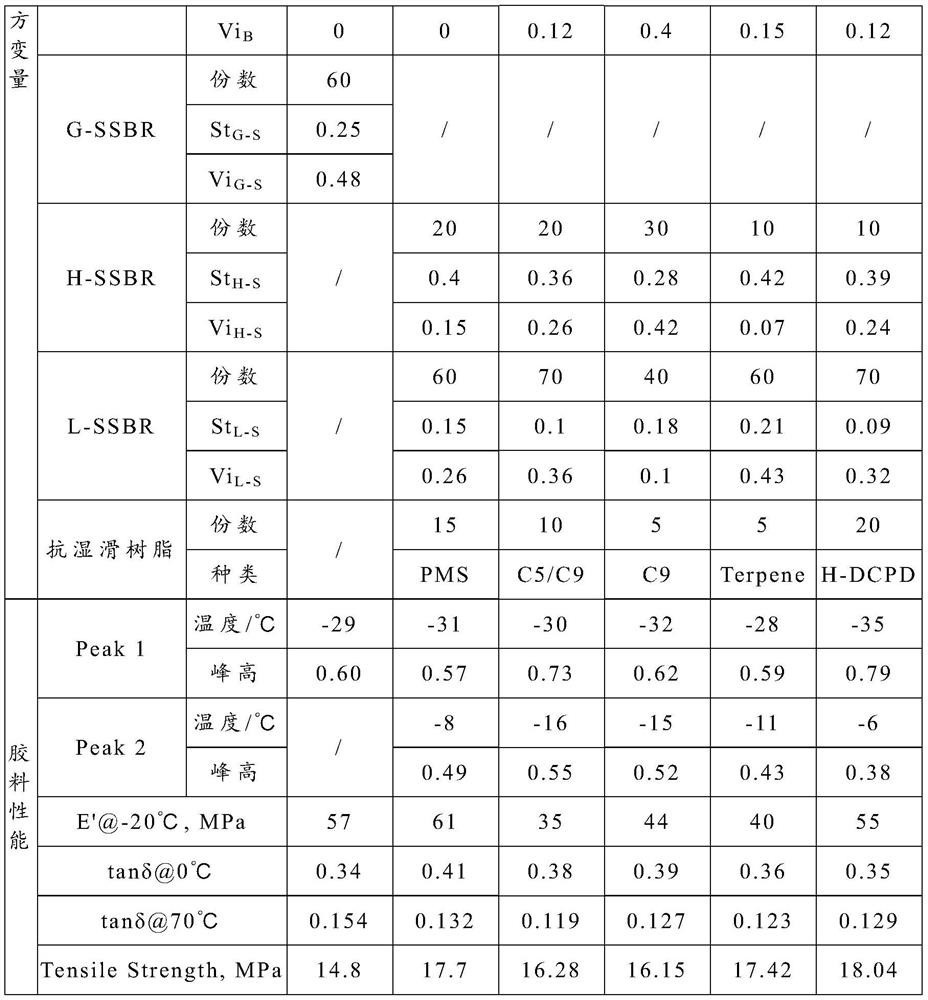

[0054] The composition of the tire tread rubber composition is shown in Table 1.

[0055] Table 1 Example 1 tire tread rubber composition formula

[0056] raw material Grade Example 1 BR CB24 20 copies L-SSBR SLR 3402 60 copies H-SSBR SLR 918S 25 copies Anti-slip resin CSR6009 15 copies Highly dispersed silica 1115MP 105 copies A silane coupling agent Si-75 6.3 parts carbon black N375 5 copies naphthenic oil N4700 28 copies Silica Dispersant CSP908 3 copies activator Precipitation Zinc Oxide 2 copies activator stearic acid 1 copy Antiaging agent 6PPD 2.5 servings Antiaging agent RD 1 copy Antiaging agent RW287 2 copies Accelerator CZ 1.6 servings Accelerator DPG 2 copies Vulcanizing agent S 1.25 servings

[0057] The above-mentioned tire tread rubber composition is mixed according to the following steps:

[0058...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com