Composite carbon material and preparation method thereof, rubber composite material and tire

A composite carbon and rubber technology, which is applied in the field of composite materials, can solve the problems of reducing the low hysteresis performance of rubber, reducing rubber hysteresis performance, and difficulty in uniform dispersion, and achieves good low hysteresis, good dispersion performance, and a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

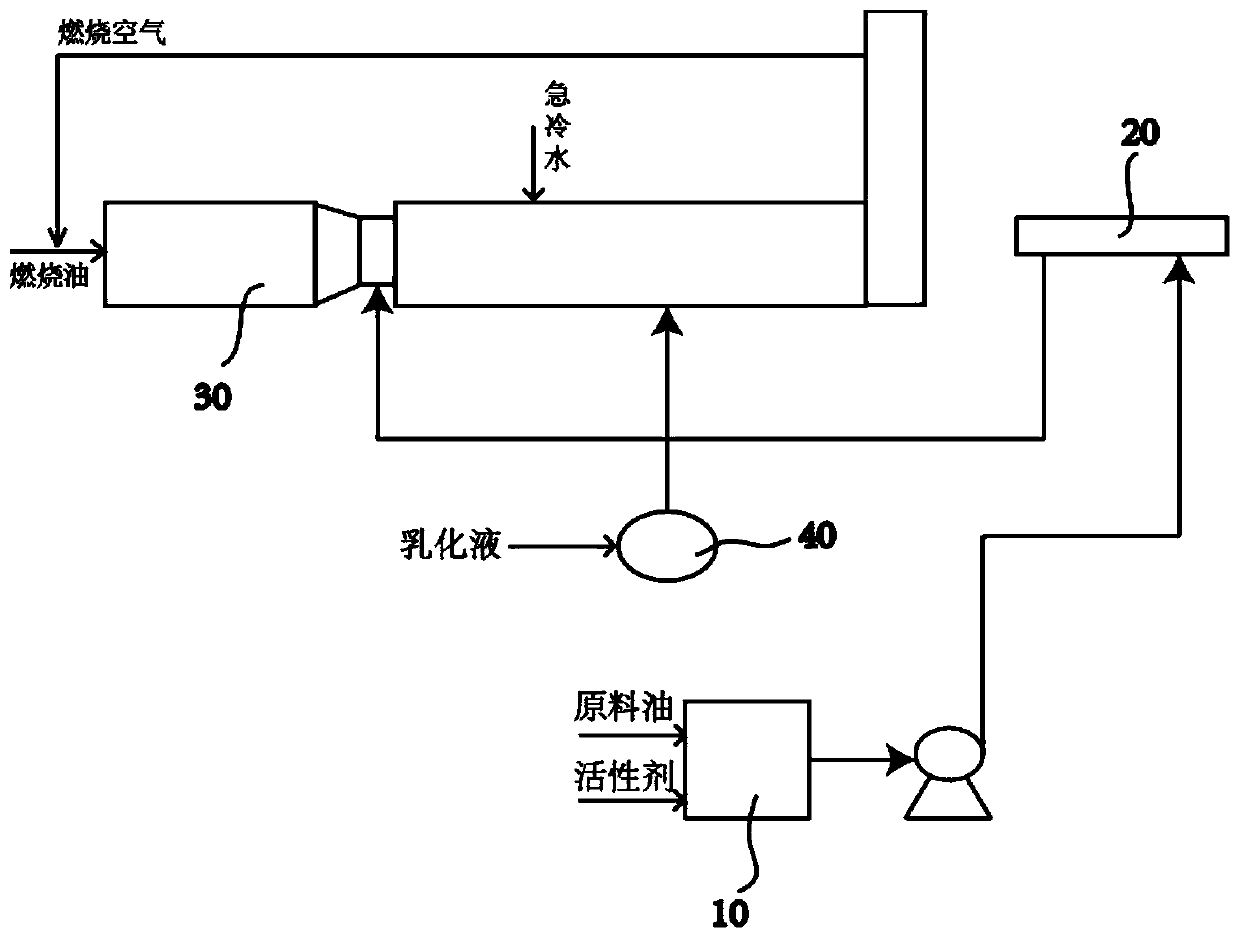

[0039] According to a first aspect of the present invention, a method for preparing a composite carbon material is provided, comprising the following steps:

[0040] (a) providing an emulsion formed by a reinforcing filler, a dispersant and water, the reinforcing filler comprising silica;

[0041] (b) mixing the raw material oil and the active agent, so that the obtained modified raw material oil is cracked, and the obtained cracked product is cooled to obtain the primary structure modified carbon black existing in the form of flue gas;

[0042] (c) Spraying the emulsion, and reacting the obtained emulsion in the form of atomized droplets with the primary structure-modified carbon black in the form of flue gas to obtain a composite carbon material.

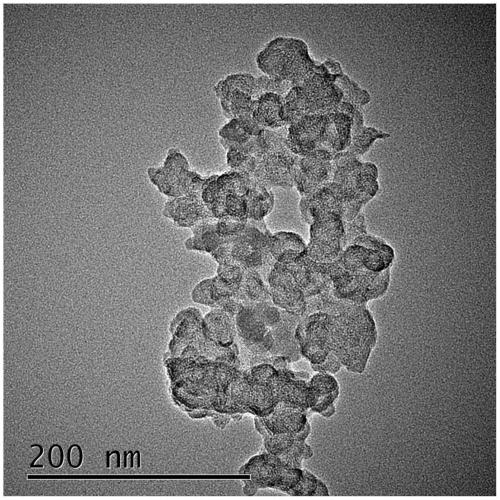

[0043] In the preparation method of the composite carbon material provided by the present invention, the atomized liquid droplets formed after spraying the emulsion of a specific composition react with the primary structure modifi...

Embodiment approach

[0061] As an optional embodiment of the present invention, in step (a), the preparation method of the emulsion comprises the following steps:

[0062] Mix and emulsify the reinforcing filler, dispersant and water to obtain an emulsion;

[0063] Preferably, the mixing temperature in the preparation method of the emulsion is 20-100°C; typical but non-limiting mixing temperatures are 20°C, 30°C, 40°C, 50°C, 60°C, 70°C, 80°C, 90°C °C or 100 °C.

[0064] More preferably, in step (a), the preparation method of emulsion comprises the following steps:

[0065] The reinforcing filler, dispersant and water are mixed in a mixer, and the temperature during mixing is controlled at 20-100°C. After mixing evenly, the mixed solution is placed in an emulsifier with shearing and grinding functions for emulsification to obtain emulsion.

[0066] Through the specific limitation of the preparation method of the emulsion, the reinforcing filler and water can be completely fused.

[0067] As an ...

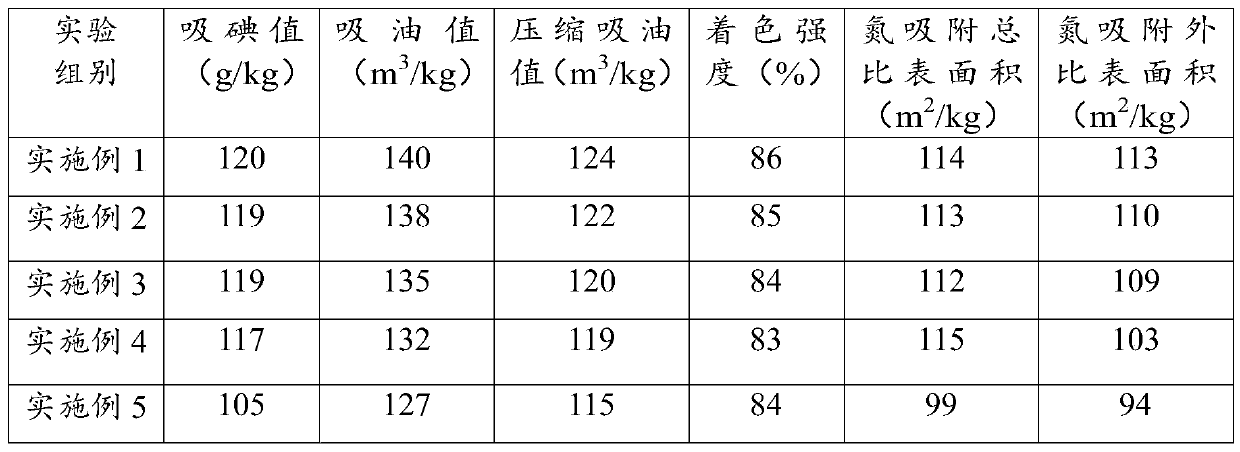

Embodiment 1

[0102] This embodiment provides a method for preparing a composite carbon material, comprising the following steps:

[0103] (a) providing an emulsion of reinforcing fillers, dispersants and water;

[0104] Mix the reinforcing filler, dispersant and water in a mixer. The mixer has stirring and heating functions. The temperature is controlled at 50°C. After mixing evenly, the mixed liquid enters an emulsifier with shearing and grinding functions for emulsification , to obtain an emulsion;

[0105] The reinforcing filler is white carbon black, and the mass fraction of the reinforcing filler in the emulsion is 5%; the dispersant is a silicon-boron coupling agent, purchased from Qingdao Siwei Chemical Co., Ltd., the brand is BF-1, and the dispersant is in the emulsion The mass fraction in is 0.5%;

[0106] (b) Feedstock oil and active agent are added in the storage tank according to the mass ratio of 100:2, and the obtained modified feedstock oil is transported to the crude oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com