Rubber composition for tire tread, and pneumatic tire

A rubber composition, tire tread technology, applied in special tires, tire parts, transportation and packaging, etc., can solve the problems of reduced rolling resistance, low affinity, insufficient and other problems, achieve excellent processability, wet road Excellent performance and low rolling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0266] Hereinafter, although an Example demonstrates this invention in detail, this invention is not limited to these Examples.

[0267]

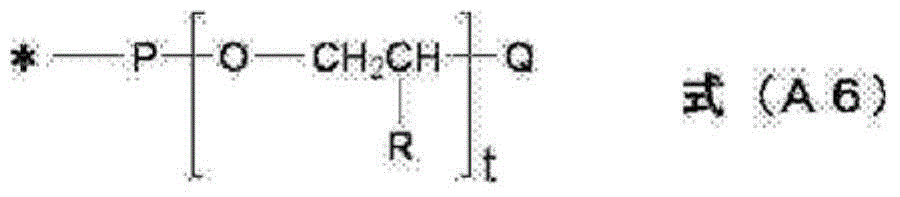

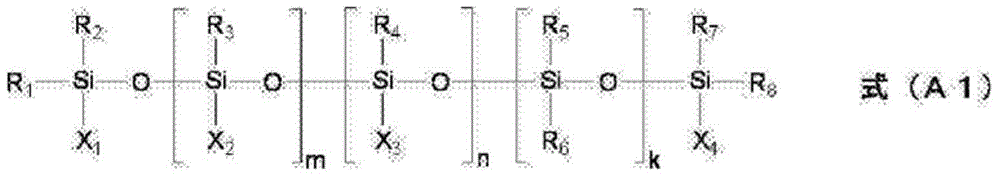

[0268] Add cyclohexane 4533g, styrene 338.9g (3.254mol), butadiene 468.0g (8.652mol), isoprene 20.0g (0.294mol) and N,N,N',N'-tetramethylethylenediamine 0.189mL (1.271mmol), start stirring. After bringing the temperature of the contents in the reaction vessel to 50° C., 5.061 mL (7.945 mmol) of n-butyl lithium was added. After the polymerization conversion rate reached approximately 100%, 12.0 g of isoprene was further added and allowed to react for 5 minutes, and then 0.281 g (0.318 mmol), let it react for 30 minutes. Furthermore, 18.3 g (0.318 mmol) of the 40 mass % xylene solution (the same follows.) of polyorganosiloxane A represented by following formula (9) was added, and it was made to react for 30 minutes. Methanol 0.5 mL was added and stirred for 30 minutes. A small amount of anti-aging agent (Irganox 1520, manufactured by BA...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption specific surface area | aaaaa | aaaaa |

| Adsorption specific surface area | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com