Rubber composition

A technology of rubber composition and compound, which is applied in transportation and packaging, rolling resistance optimization, special tires, etc., can solve problems such as mechanical strength, wear resistance physical properties may not be sufficient, rubber performance changes, filler dispersion is insufficient, etc. Excellent wear resistance, improved rolling resistance, and various performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

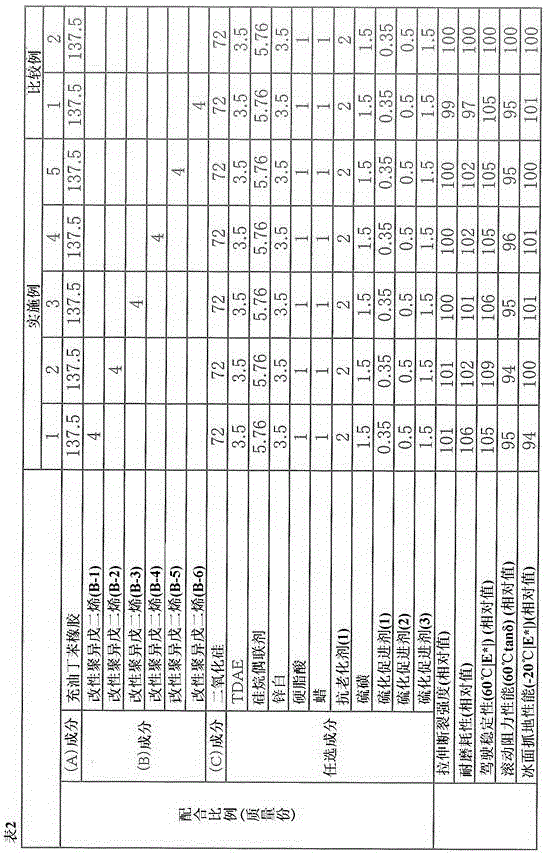

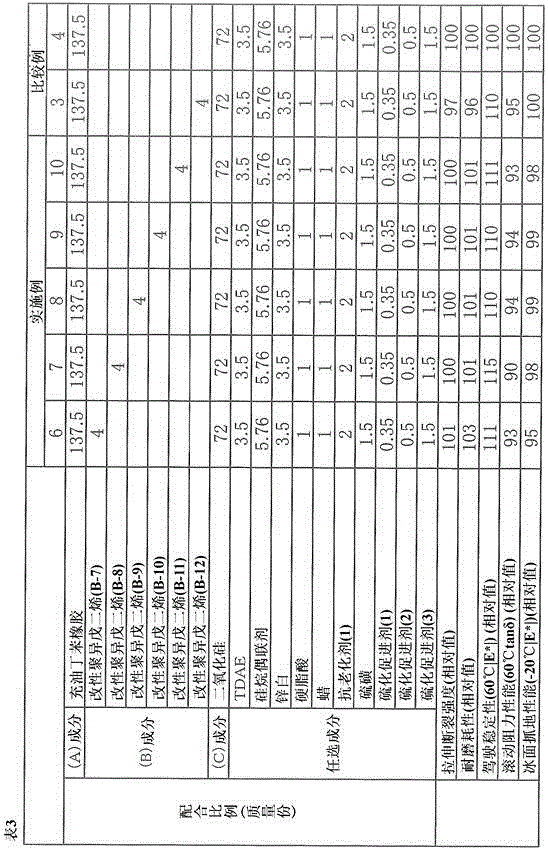

[0160] Hereinafter, although an Example demonstrates this invention in more detail, this invention is not limited to these Examples.

[0161] Each component used in this Example and a comparative example is as follows.

[0162]

[0163] Oil-extended styrene-butadiene rubber: JSR1723 (manufactured by JSR Corporation)

[0164] (rubber component: 100 parts by mass, oil component: 37.5 parts by mass)

[0165] Styrene-butadiene rubber: JSR1500 (manufactured by JSR Corporation).

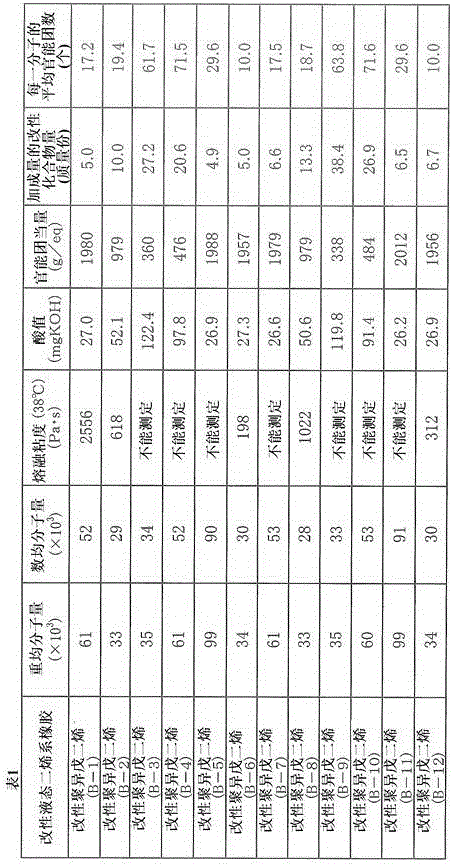

[0166]

[0167] Modified liquid polyisoprene obtained in Production Examples 1 to 12 described later.

[0168]

[0169] Silica: ULTRASIL7000GR (manufactured by Ebonick Degusa Japan).

[0170]

[0171] Sulfur (micronized sulfur 200 mesh, manufactured by Tsurumi Chemical Industry Co., Ltd.).

[0172]

[0173] Vulcanization accelerator (1): ノクセラー CZ-G (manufactured by Ouchi Shinko Chemical Industry Co., Ltd.)

[0174] Vulcanization accelerator (2): ノクセラー D (manufactured by Ouchi Shinko Chemical...

manufacture example 1

[0184] Production Example 1: Production of Modified Liquid Polyisoprene (B-1)

[0185] The fully dried 5L autoclave was replaced with nitrogen, 1200g of hexane and 12.6g of n-butyllithium (17% by mass hexane solution) were added, the temperature was raised to 50°C, and the polymerization temperature was controlled to reach 50°C under stirring. Simultaneously, 1200 g of isoprene was gradually added and polymerized for 1 hour. Methanol was then added to terminate the polymerization reaction to obtain a polymer solution. Water was added to the obtained polymer solution and stirred, and the polymer solution was washed with water. After the stirring was completed and the separation of the polymer solution phase and the water phase was confirmed, water was separated. The polymer solution after washing was vacuum-dried at 70° C. for 24 hours to obtain unmodified liquid polyisoprene (B′-1).

[0186] Next, 300 g of the obtained unmodified liquid polyisoprene (B'-1) was charged into ...

manufacture example 2

[0187] Production Example 2: Production of Modified Liquid Polyisoprene (B-2)

[0188] The fully dried 5L autoclave was replaced with nitrogen, 1200g of hexane and 26.2g of n-butyllithium (17% by mass hexane solution) were added, the temperature was raised to 50°C, and the polymerization temperature was controlled to reach 50°C under stirring. Simultaneously, 1200 g of isoprene was gradually added and polymerized for 1 hour. Methanol was then added to terminate the polymerization reaction to obtain a polymer solution. Water was added to the obtained polymer solution and stirred, and the polymer solution was washed with water. After the stirring was completed and the separation of the polymer solution phase and the water phase was confirmed, water was separated. The polymer solution after washing was vacuum-dried at 70° C. for 24 hours to obtain unmodified liquid polyisoprene (B′-2).

[0189] Next, 300 g of the obtained unmodified liquid polyisoprene (B'-2) was charged into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com