Lithium ion battery

A lithium-ion battery, polymer technology, applied in battery electrodes, secondary batteries, non-aqueous electrolyte battery electrodes, etc., can solve the problem of battery short circuit, separator and pole piece dislocation, ceramic layer and pole piece cannot form adhesion And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Pole piece preparation:

[0034] Preparation of positive electrode sheet:

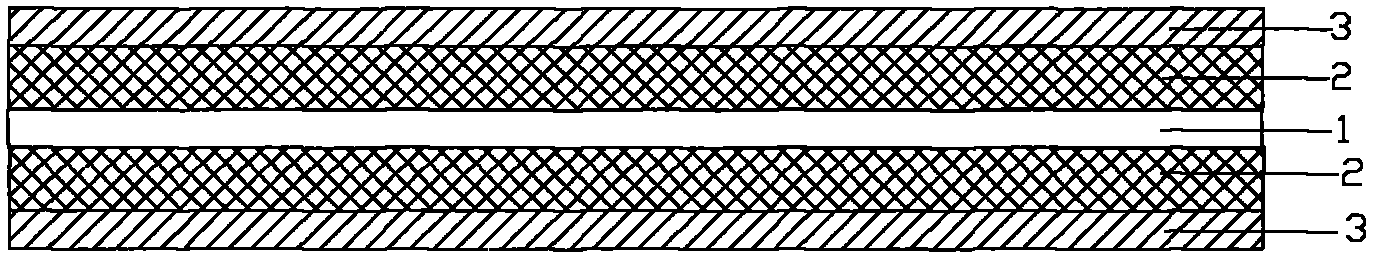

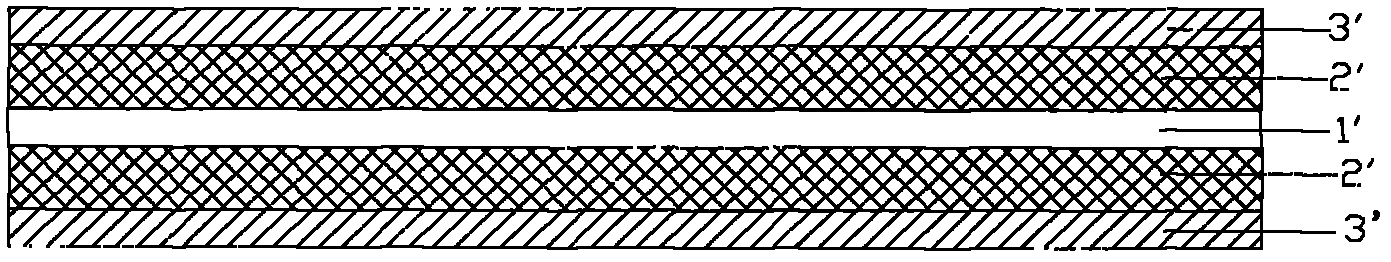

[0035] The positive electrode active material, the binder and the conductive material are mixed in the solvent according to the proportion, and after uniform stirring, the positive electrode slurry is obtained. Coating the positive electrode slurry on the positive electrode current collector 1, drying, and cold pressing to obtain the positive electrode active material layer 2, and then cutting into pieces and welding tabs to obtain the positive electrode sheet to be processed.

[0036] Polyacrylonitrile (PAN) is formulated into a solution, then coated on the surface of the positive electrode active material layer 2 by printing and coating, and dried to obtain a positive electrode polymer bonded with a thickness of 0.1 μm and a porosity of 30%. Layer 3.

[0037] Preparation of negative electrode sheet:

[0038]The negative electrode active material, the binder and the conductive material are m...

Embodiment 2

[0046] The difference with embodiment 1 is:

[0047] The positive polymer adhesive layer 3 is a polyoxyethylene (PEO) layer with a thickness of 0.5 μm and a porosity of 40%.

[0048] The negative electrode polymer bonding layer 3' is a polyacrylonitrile (PAN) layer with a thickness of 1 μm and a porosity of 40%.

[0049] Preparation of diaphragm:

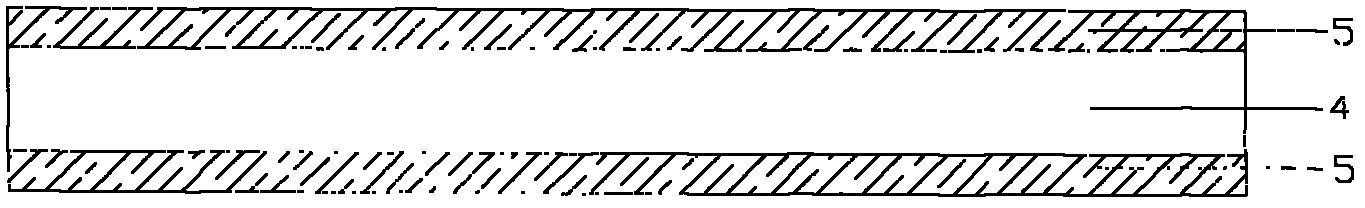

[0050] Using a polypropylene (PP) porous membrane as the porous membrane substrate 4, the surface of the porous membrane substrate 4 is firstly treated with a raising agent to increase its surface tension.

[0051] Silicon dioxide (SiO 2 ) ceramic particles are fully mixed with polyvinylidene fluoride (PVDF) solution to obtain a ceramic material. Then, the ceramic material is coated on both surfaces of the porous membrane substrate 4 by printing and coating, and dried to obtain a ceramic material layer 5 with a thickness of 1 μm.

[0052] The rest are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0054] The difference with embodiment 1 is:

[0055] The positive polymer adhesive layer 3 is a polyvinylidene fluoride (PEO) layer with a thickness of 2 μm and a porosity of 30%.

[0056] The negative electrode polymer bonding layer 3' is a polyacrylonitrile (PAN) layer with a thickness of 2 μm and a porosity of 50%.

[0057] Preparation of diaphragm:

[0058] Use polypropylene / polyethylene / polypropylene (PP / PE / PP) porous film as the porous film substrate 4, first adopt the pressure roller with uneven surface to press the porous film, and carry out surface treatment to the porous film substrate 4, to increase its surface tension.

[0059] Titanium dioxide (TiO 2 ) The ceramic particles are fully mixed with the styrene-butadiene rubber (SBR) solution to obtain a ceramic material. Then, the ceramic material was coated on both surfaces of the porous membrane substrate 4 by means of transfer coating, and dried to obtain a ceramic material layer 5 with a thickness of 3 μm.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com