Method for preparing high-specific surface area porous carbon material based on oil tea seed husk and application thereof

A technology of high specific surface area and porous carbon materials, which is applied in the preparation of biomass carbon materials and the field of preparation of biomass porous carbon materials, can solve the problems of waste of resources, environment and pollution, and achieve simple production process, wide sources and good dispersion sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

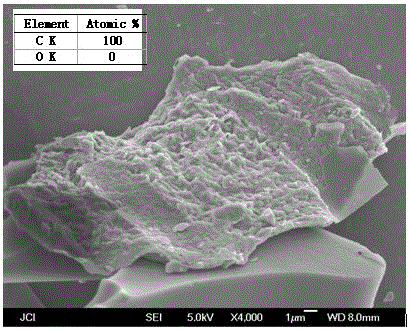

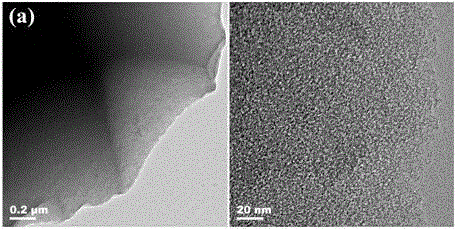

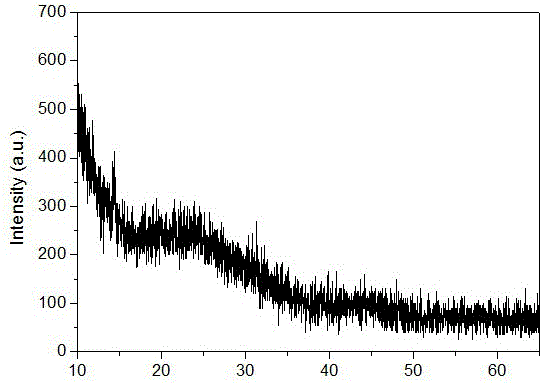

[0022] Example 1: Preparation of High Specific Surface Area Porous Carbon Material

[0023] Add 2.0g of Camellia oleifera seed shell powder (through a 74μm sieve) into 60ml of deionized water, stir and swell on a magnetic stirrer for 6h, then transfer to a 100ml polytetrafluoroethylene-lined reactor, pass through nitrogen to remove oxygen The reaction kettle was placed in a blast drying oven at 230°C for constant temperature reaction for 12 hours. The reactor was naturally cooled to room temperature, the upper liquid was poured out, and the solid was taken out. Sequentially ultrasonically cleaned with deionized water and absolute ethanol until the washing liquid was colorless, the mixture was vacuum filtered, and the obtained solid was dried in a drying oven at 60°C to obtain a black powder substance. Take 0.5g of the above powder and place it in a mortar, add 2g KOH for thorough grinding, then place the mixed sample in a porcelain boat, heat and activate it in a tube furnace...

Embodiment 2

[0024] Example 2: Static adsorption experiment of heavy metal Cr6+ by porous carbon material with high specific surface area

[0025] Accurately pipette 40ml of solutions with initial concentrations of 10mg / L, 30mg / L, 50mg / L, 70mg / L, 90mg / L, 110mg / L, 130mg / L, and 150mg / LCr6+ into eight 100ml Erlenmeyer flasks with stoppers , use 0.1mol / LH2SO4 and 0.1mol / LNaOH to adjust the pH value of the solution to 2, then weigh 10mg of the carbon material powder prepared by the present invention and add them to the conical flask, after mixing, let the conical flask be placed in a constant temperature oscillator at 150r Equilibrate under the condition of 24h / min, take 5mL sample mixture after shaking, centrifuge at 8500r / min for 2min, take an appropriate amount of supernatant and use diphenylcarbazide spectrophotometry to develop color, and then measure the solution at 540nm The absorbance was calculated by drawing a standard curve to calculate the concentration of Cr6+ in the solution. The...

Embodiment 3

[0026] Example 3: Static adsorption experiment of methylene blue by porous carbon material with high specific surface area

[0027] Accurately pipette 20ml of the initial concentrations of 50mg / L, 100mg / L, 150mg / L, 180mg / L, 200mg / L, 220mg / L, 250mg / L, 300mg / LMB solutions into eight 50ml stoppered Erlenmeyer flasks , use 0.1mol / LHCl and 0.1mol / LNaOH to adjust the pH value of the solution to 8, then weigh 10mg of the carbon material powder prepared by the present invention and add them to the conical flask, and after mixing, let the conical flask be placed in a constant temperature shaker at 150r Equilibrate under the condition of 12h / min, take 5mL of sample mixture after shaking, centrifuge at 8500r / min for 2min, take 1mL of supernatant, measure the absorbance of the solution at 665nm by spectrophotometry, and calculate the concentration in the solution by drawing a standard curve MB concentration. The equilibrium adsorption amount qe was plotted against the equilibrium concent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com