Preparation method of halogen-free flame-retardant polypropylene foam material

A flame retardant polypropylene and foam material technology, applied in the field of polypropylene material preparation, can solve the problems affecting the mechanical properties of halogen-free flame retardant polypropylene foam materials, and achieve excellent flame retardant properties and mechanical properties, intact structure, foam The effect of uniform distribution of pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] According to the number of parts by mass, weigh 100 parts of polypropylene, 15 parts of ammonium polyphosphate, 5 parts of pentaerythritol, 1 part of talcum powder, and 1 part of antioxidant, stir and mix at high speed in a mixer, and extrude through twin-screw at 200 ° C. Wire drawing, pelletizing in cold water to obtain particles with a particle size of 0.8-1.2 mm and a length of 1.2-1.5 mm.

[0059] Put 5kg of blend particles, 20kg of water, 100g of nanoclay, and 50g of calcium stearate into the reaction kettle, add 550g of carbon dioxide, heat to 140°C, and maintain the pressure at 2.3MPa for 30 minutes. Unload to atmospheric pressure, dry, obtain 20 times expanded polypropylene beads, its density is 0.045g / cm 3 .

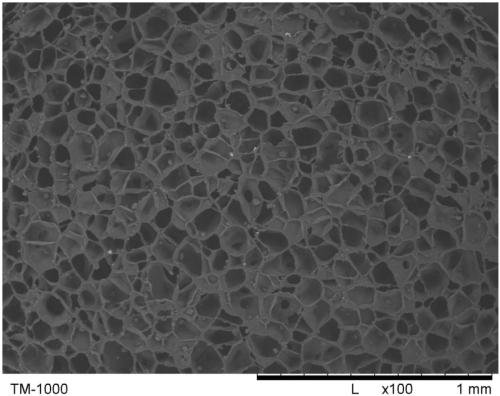

[0060] figure 1 The electron microscope picture of the cross-section of the expanded polypropylene beads prepared in this example shows that the internal cells are uniform.

[0061] The foamed polypropylene beads were loaded in a 0.6MPa pressure tank ...

Embodiment 2

[0063] In parts by mass, 100 parts of polypropylene, 2 parts of zinc borate, 1 part of antioxidant, 15 parts of tricresyl phosphate, 5 parts of pentaerythritol, and 5 parts of melamine are stirred and mixed at high speed in a mixer, and added to a twin-screw extruder , under the condition of 200 ℃, through twin-screw extrusion, drawing, pelletizing in cold water, and passing through a pelletizer to obtain particles with a diameter of 0.8-1.2mm and a length of 1.2-1.5mm.

[0064] Put 5kg of blend particles, 15kg of water, 80g of montmorillonite, 40g of calcium stearate, and 0.1kg of pentane into the reaction kettle, add 400g of carbon dioxide, heat to 137°C, maintain the pressure at 2.1MPa for 30 minutes, and quickly release the pressure Valve, within 30 seconds, the material in the kettle is discharged to atmospheric pressure, and dried to obtain 15 times expanded polypropylene beads with a density of 0.06g / cm 3 .

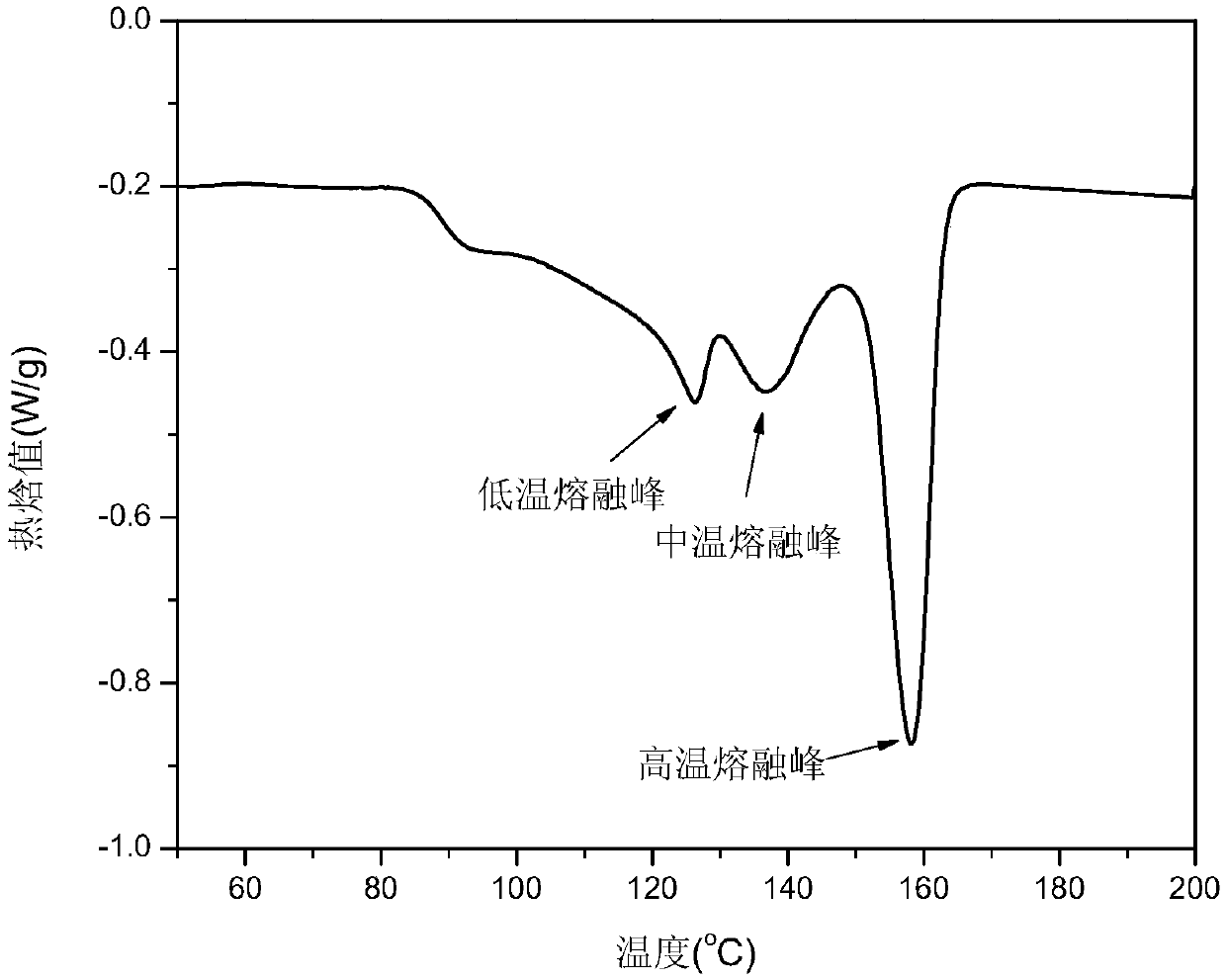

[0065] figure 2 DSC melting curve of expanded polypropylen...

Embodiment 3

[0068] In parts by mass, 100 parts of polypropylene, 1 part of talcum powder, 1 part of antioxidant, 20 parts of melamine phosphate, and 10 parts of pentaerythritol were stirred and mixed at high speed in a mixer, and then added to a twin-screw extruder. Under the condition of ℃, it is extruded by twin-screw, drawn, pelletized by cold water, and pelletized by a pelletizer to obtain particles with a diameter of 0.8-1.2mm and a length of 1.2-1.5mm.

[0069] Put 5kg of blend particles, 25kg of water, 160g of kaolin, and 80g of sodium benzenesulfonate into the reaction kettle, add 700g of carbon dioxide, raise the temperature to 139°C, maintain the pressure at 2.5MPa for 30 minutes, pass through the rapid pressure relief valve, and within 30 seconds, the kettle The inner material is unloaded to atmospheric pressure and dried to obtain 15 times expanded polypropylene beads with a density of 0.06g / cm 3 .

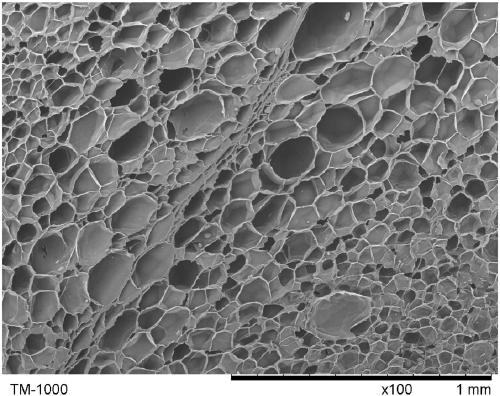

[0070] The foamed polypropylene beads were pressured in a 0.5MPa pressure ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com