Foaming inhibitor and application thereof

A foaming inhibitor and reflux reaction technology, applied in the field of foaming inhibitors, can solve the problems of unstable product foaming ratio, affecting product quality stability, and non-fine product feel, so as to ensure the foaming inhibitory effect and ensure product quality. Stable quality and fine feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

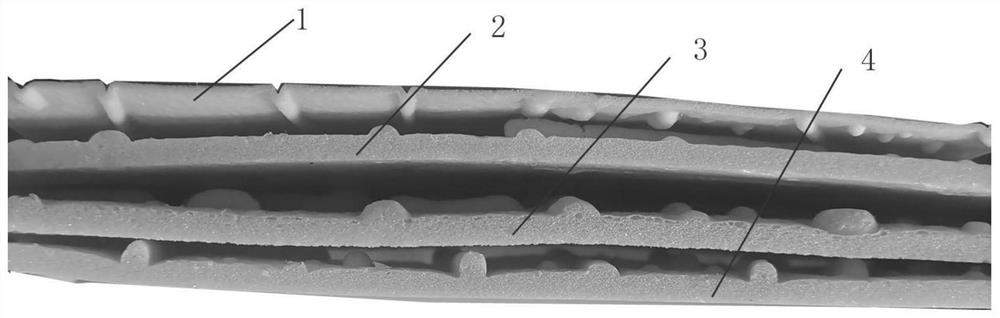

Image

Examples

Embodiment 1

[0025] Example 1: A foaming inhibitor prepared by the following steps: mixing acid anhydride and nonanol, and reflux reaction at a temperature of 180° C. for 2 hours; the mass ratio of the acid anhydride to nonanol is 1:1, so Described acid anhydride is phthalic anhydride and maleic anhydride, and the mass ratio of phthalic anhydride and maleic anhydride is 3:7.

Embodiment 2

[0026] Example 2: A foaming inhibitor prepared by the following steps: mixing acid anhydride and nonanol, and reflux reaction at a temperature of 190° C. for 1 h; the mass ratio of the acid anhydride to nonanol is 1:1, so Described acid anhydride is phthalic anhydride and maleic anhydride, and the mass ratio of phthalic anhydride and maleic anhydride is 3:7.

Embodiment 3

[0027] Example 3: A foaming inhibitor prepared by the following steps: mixing acid anhydride and nonanol, and reflux reaction at a temperature of 185° C. for 1.5 h; the mass ratio of the acid anhydride to nonanol is 1:1, The acid anhydride is phthalic anhydride and maleic anhydride, and the mass ratio of phthalic anhydride and maleic anhydride is 3:7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com