Coating emulsion and preparation method thereof

An emulsion and coating technology, applied in the coating and other directions, can solve the problem of insufficient water resistance, and achieve the effects of good washing resistance, good water resistance, and good calcium ion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

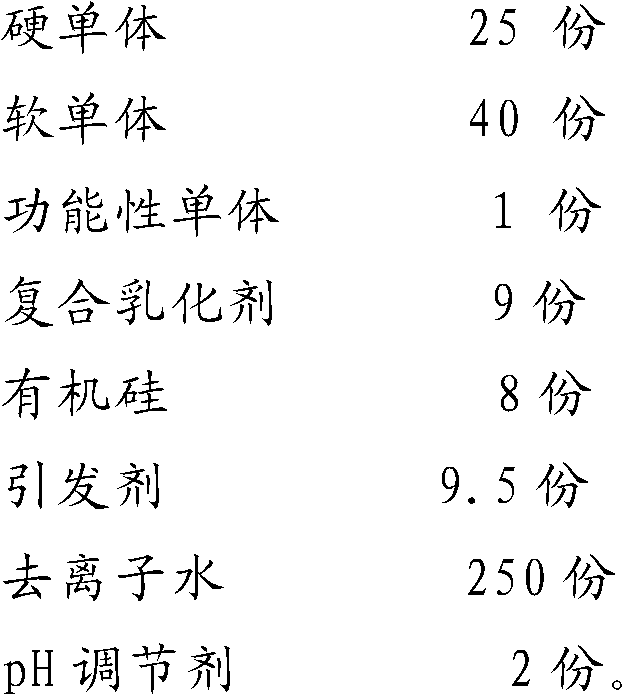

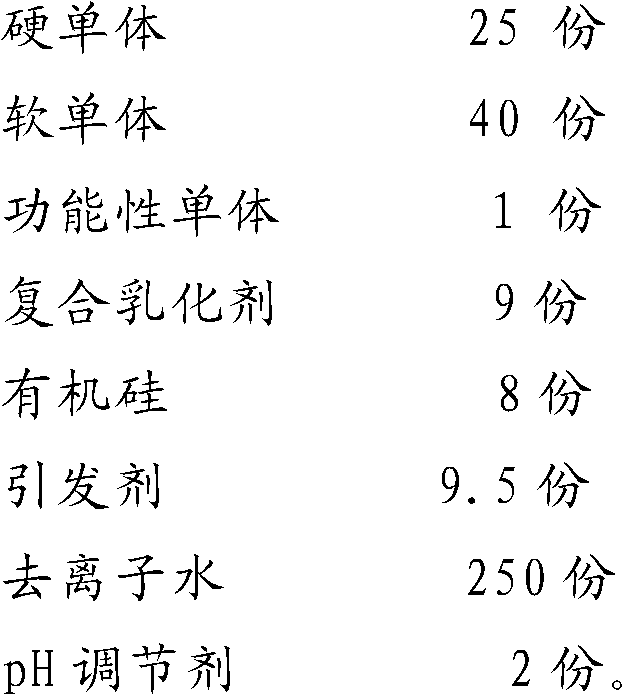

Method used

Image

Examples

Embodiment

[0036] A. First, add 2 parts by weight of compound emulsifier and 20 parts by weight of deionized water into the polymerization reactor, stir and heat up;

[0037] B. 30 parts by weight of deionized water, 7 parts by weight of composite emulsifier, 25 parts by weight of hard monomer (the compounding of styrene and 18 parts by weight of methyl methacrylate) are added in the pre-emulsification kettle, Under the condition of constant speed (820 rev / min), after stirring for 120 minutes, the pre-emulsion was obtained, and 3.72 parts by weight thereof were weighed as the bottom seed reaction solution for subsequent use;

[0038] C. Raise the temperature of the polymerization reactor in step A to 65-70°C, drop in 3.72 parts by weight of the bottom seed reaction solution in step B, then add 1 part by weight of the bottom initiator to react for 100-120 minutes, and pour into the polymerization reactor Continue to add 200 parts by weight of deionized water, slowly lower the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com