Preparation method of and product of modified polyvinyl acetate emulsion adhesive

A technology of polyvinyl acetate and latex adhesive, which is applied in the direction of monocarboxylate copolymer adhesives, adhesive additives, adhesive types, etc., and can solve the problems of decreased bonding strength, easy delamination, and film-forming creep resistance Poor denaturation and other problems, to achieve the effect of improving water resistance and cold resistance, high safety factor in use, and good adhesive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The preparation of the modified polyvinyl acetate emulsion adhesive should pay attention to the following matters in the reaction:

[0051] 1. The agitation in the reaction vessel cannot be stopped all the time. When it is cooled to room temperature, the white latex product is obtained. Stop agitation, discharge and pack.

[0052] 2. When the viscosity of the adhesive is too high and the water resistance is poor, the amount of polyvinyl alcohol in the formula can be appropriately reduced.

[0053] 3. If the stability of the adhesive is poor, the amount of some initiators in the formula can be appropriately reduced. If it is too small, it will not initiate, making it difficult to polymerize the monomer.

[0054] 4. If the white latex product has a lot of foam, an appropriate amount of defoamer can be added.

[0055] 5. Pay attention to the dosage and adding time of the initiator. When the reflux starts to appear, if the reflux flow is large, it indicates that the initia...

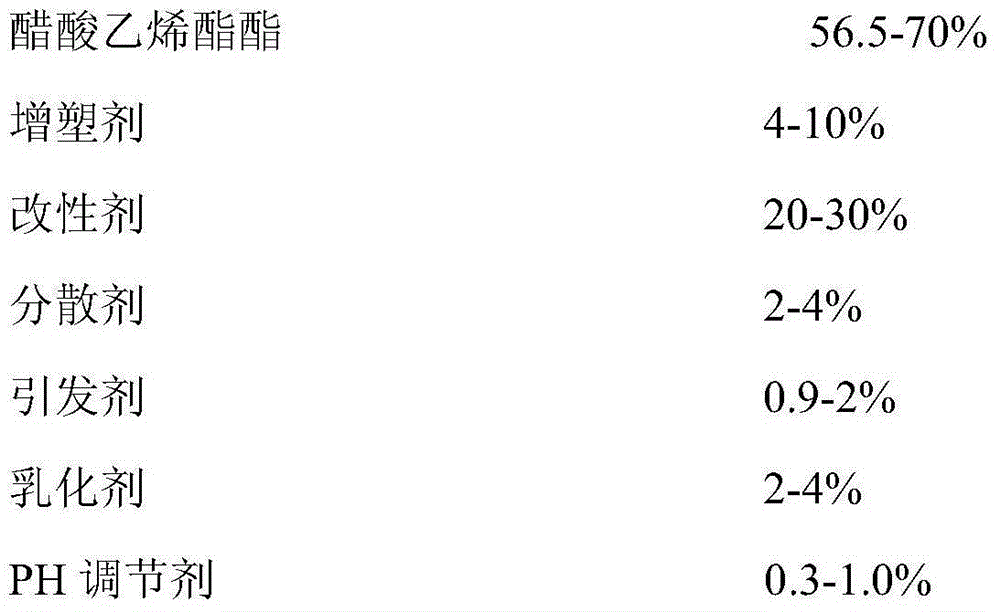

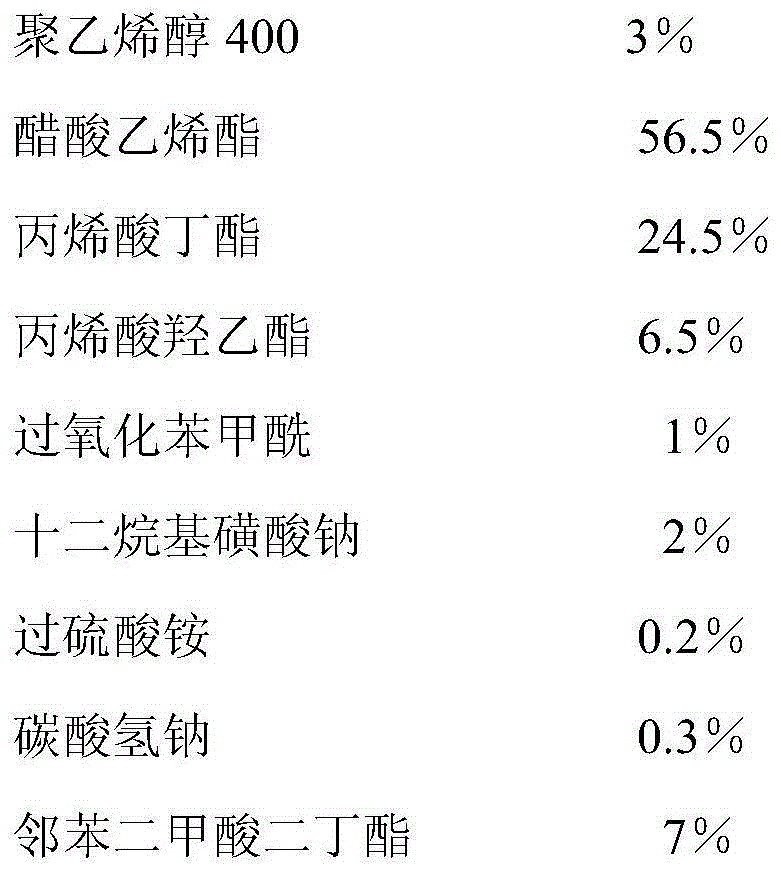

Embodiment 1

[0059] Dosing reaction reagents according to the following mass percentages for preparation:

[0060]

[0061] Wherein deionized water: the mass percent of vinyl acetate is 2:1.

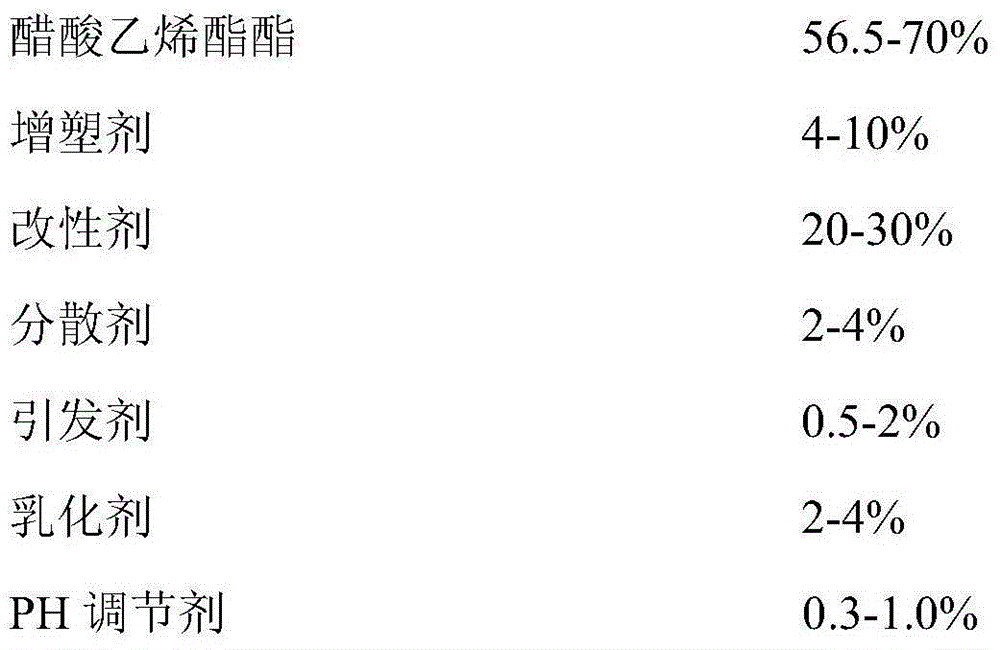

Embodiment 2

[0063] Dosing reaction reagents according to the following mass percentages for preparation:

[0064]

[0065] Wherein the mass percent of deionized water: vinyl acetate is 3:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com