Preparation method of isocyanate curing agent-modified water-based acrylate composite metal anticorrosive paint

A water-based acrylic and isocyanate technology, used in anti-corrosion coatings, coatings, etc., can solve the problems of low overall strength of coatings, poor anti-corrosion effect, low comprehensive performance, etc., achieve good surface sag resistance, improve anti-corrosion effect, strong Restorative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

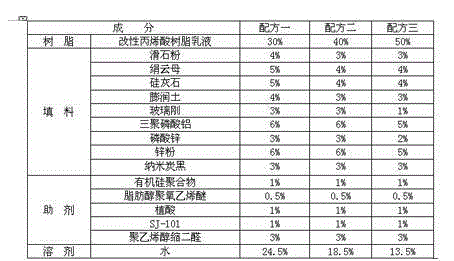

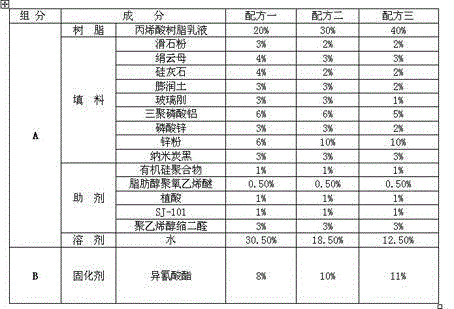

[0018] The preparation method of one-component water-based anticorrosion coating:

[0019] A kind of preparation method of the waterborne acrylic composite metal anticorrosion paint modified by isocyanate curing agent, described preparation method comprises the following steps:

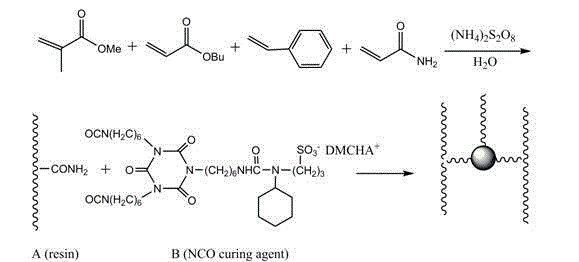

[0020] (1) Preparation of water-based acrylic resin emulsion modified by isocyanate curing agent: add 10g of PVA aqueous solution, 1g of sodium bicarbonate, 2g of TX- 10. 185g of deionized water, adjust the temperature to 60-90°C, add 1.5g of ammonium persulfate, and stir well. Then weigh the mixed solution containing 130g n-butyl acrylate, 20g methyl methacrylate, 20g styrene, and 30g acrylamide, use a constant pressure dropping funnel to drop it at a constant speed for 3 hours, keep it warm for 1h, and then drop it to room temperature , slowly add 10 g of HDI trimer, react for 0.5 h, and prepare a water-based acrylic resin emulsion modified by an isocyanate curing agent;

[0021] (2) Preparation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com