Water emulsion type plant adhesive and preparation method thereof

An adhesive, water-emulsion type technology, applied in the field of water-emulsion type plant adhesive, to achieve the effect of reducing energy consumption, eliminating transfer and ensuring cohesive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

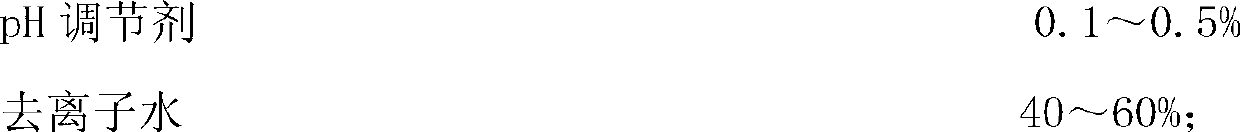

[0028] The preparation method of above-mentioned water-emulsion type bead-planting adhesive comprises the following steps:

[0029] Take each raw material according to the above formula, dissolve the initiator with 2% deionized water weight given in the raw material to obtain the initiator solution, and dissolve tert-butyl with 1% deionized water weight given in the raw material Base hydrogen peroxide, with the deionized water solution pH adjusting agent of the deionized water weight 2% that provides in the raw material;

[0030] To prepare the seed emulsion:

[0031] Use deionized water accounting for 15% by weight of deionized water, all buffers, emulsifiers accounting for 0.5% by weight of emulsifier and styrene or methyl methacrylate accounting for 3% by weight of styrene or methyl methacrylate as Polymerize the monomer, carry out pre-emulsification, stir at a constant speed of 50Hz for 20-30 minutes, put it in a water bath and heat it to 80-82°C, take the initiator solut...

Embodiment 1

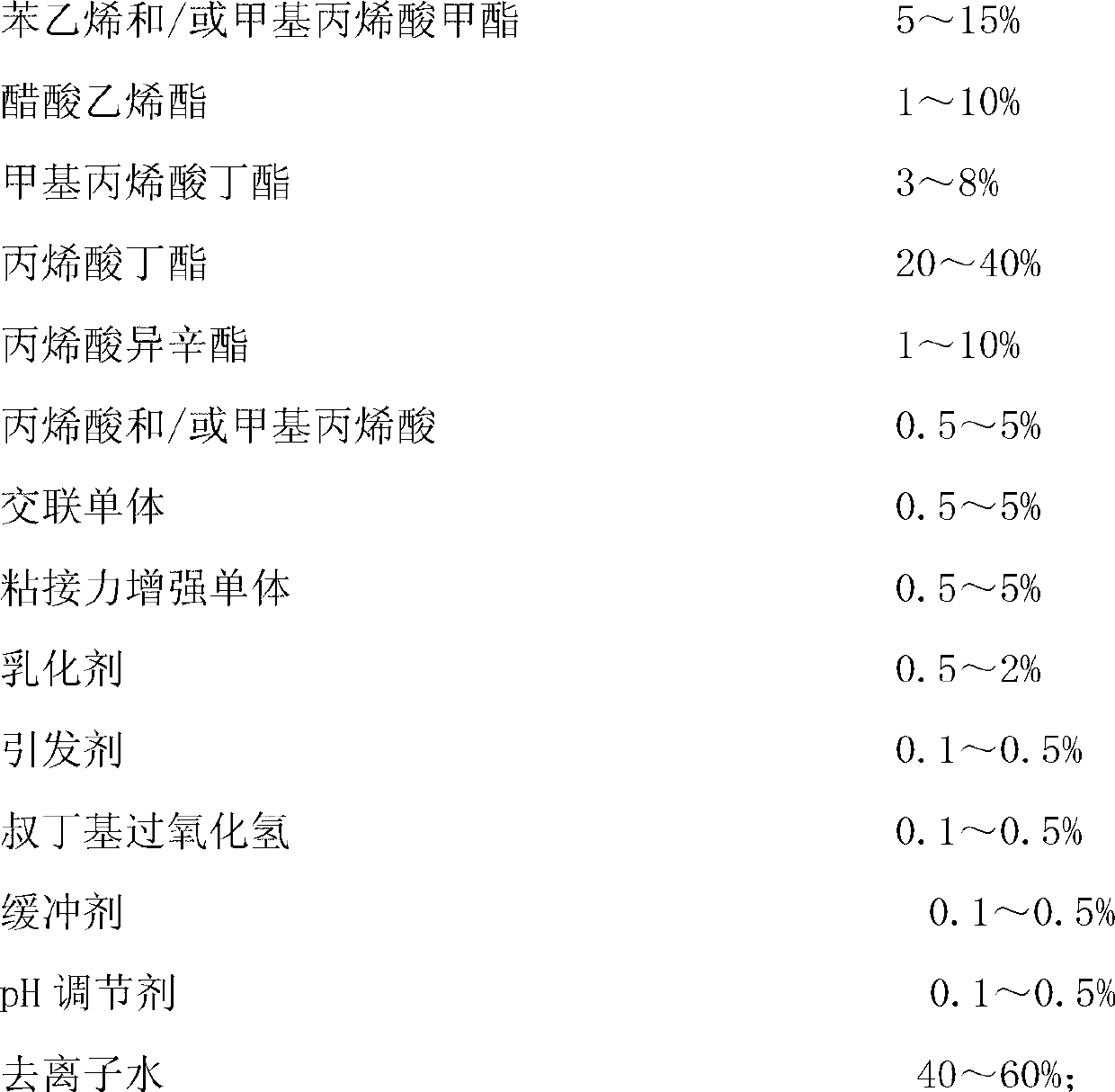

[0038] After the core-shell emulsion radical polymerization is carried out on each component in the following table, the obtained polymer emulsion is the water-emulsion type bead-planting adhesive.

[0039] raw material

By mass percentage

6

[0040] vinyl acetate

6

3

24

5

2

Hydroxyethyl Acrylate (Crosslinking Monomer)

2

Urea ring functional monomer (adhesion enhancing monomer)

1

Sodium Lauryl Sulfate (Emulsifier)

0.8

Potassium persulfate (initiator)

0.5

tert-butyl hydroperoxide

0.3

Sodium bicarbonate (buffer)

0.5

0.4

Deionized water

48.5

[0041] The specific preparation method is as follows:

[0042] With the deionized water dissolution initiator of 2% of the deionized water weight given in the raw ...

Embodiment 2

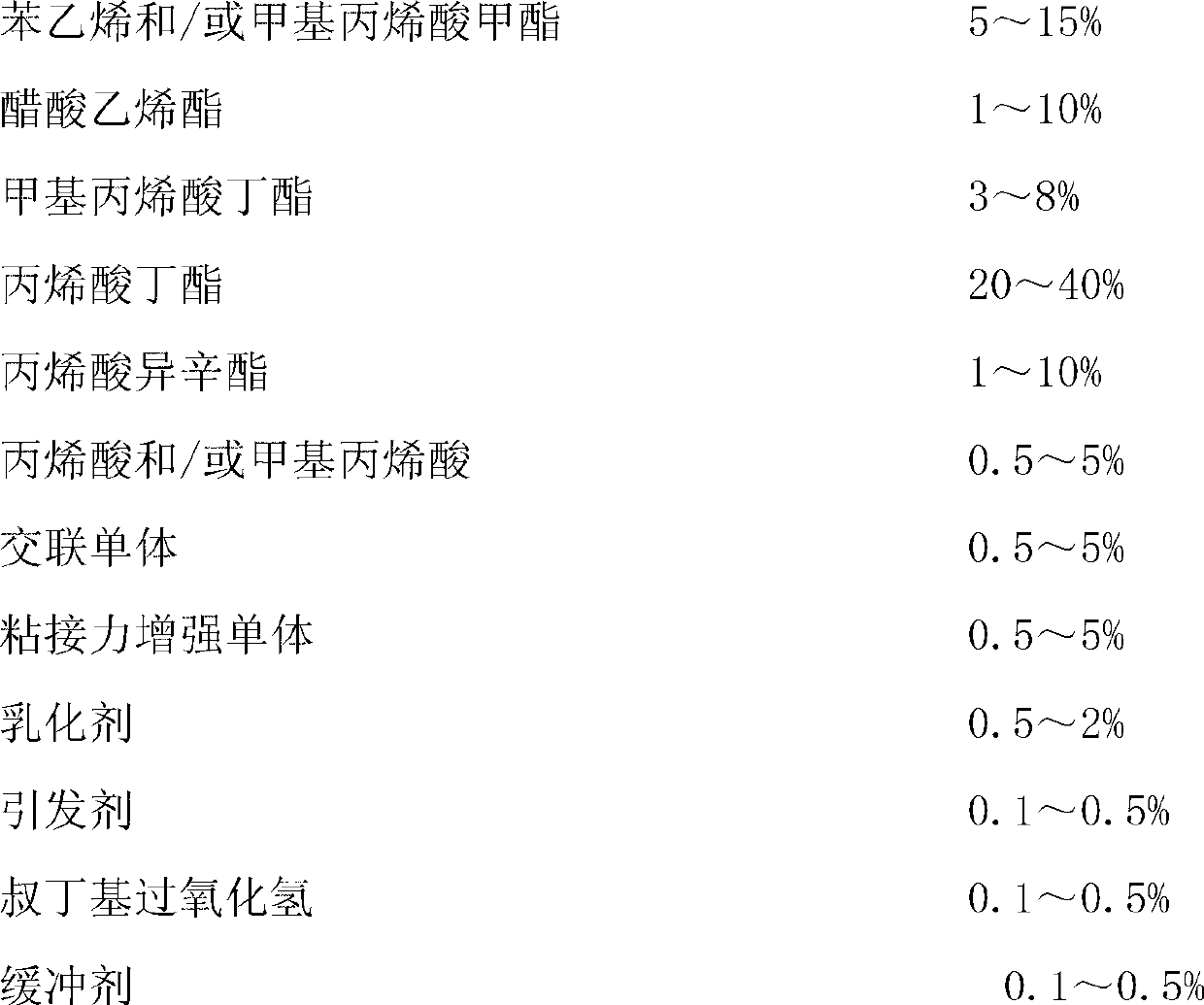

[0050] After the core-shell emulsion radical polymerization is carried out on each component in the following table, the obtained polymer emulsion is the water-emulsion type bead-planting adhesive.

[0051] raw material

By mass percentage

9

3

4

20

9

acrylic

2

Glycidyl methacrylate (crosslinking monomer)

3

Urea ring functional monomer (adhesion enhancing monomer)

2

Sodium Lauryl Sulfate (Emulsifier)

0.8

NP-10 (emulsifier)

0.4

Ammonium persulfate (initiator)

0.3

tert-butyl hydroperoxide

0.3

Sodium bicarbonate (buffer)

0.4

0.5

Deionized water

45.3

[0052] The specific preparation method is basically the same as in Example 1, see Example 1.

[0053] After the water-emulsion type bead-planti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com