Synthetic styrene-acrylic latex

A technology of styrene-acrylic latex and hydroxypropyl latex, which is applied in the field of synthetic styrene-acrylic latex, can solve the problems of uneven product quality, poor water resistance, and large usage, and achieve good mechanical processing adaptability, strong adhesion, and less foaming Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

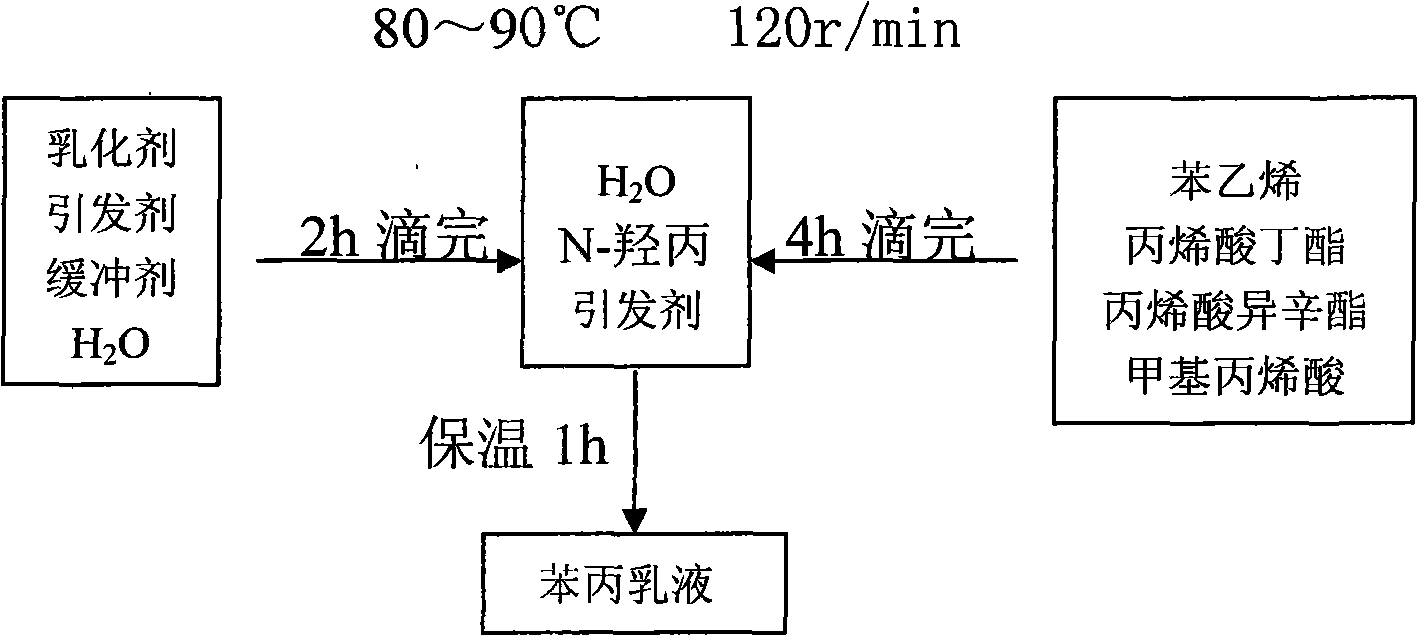

Method used

Image

Examples

Embodiment 1

[0034] A synthetic styrene-acrylic latex, the raw material of which has the following components by weight:

[0035] Methacrylic acid 2

[0036] Isooctyl acrylate 5

[0037] Styrene 10

[0038] Butyl acrylate 6

[0039] Alkylphenol polyoxyethylene (10) ether 0.4

[0040] Ammonium persulfate 0.1

[0041] Ionized water 65.

[0042] Dodecylbenzene sulfonic acid 0.1

[0043] Acrylamide 0.4

[0044] Diethanolamine 0.4

[0045] N-Hydroxypropyl solution 0.3.

Embodiment 2

[0047] A synthetic styrene-acrylic latex, the raw material of which has the following components by weight:

[0048] Acrylic 4

[0049] Isooctyl acrylate 8

[0050] Styrene 15

[0051] Butyl acrylate 9

[0052] .Alkylphenol polyoxyethylene (10) ether 0.8

[0053] Ammonium persulfate 0.4

[0054] Ionized water 80

[0055] Dodecylbenzene sulfonic acid 0.5

[0056] Acrylamide 0.8

[0057] Diethanolamine 0.8

[0058] N-Hydroxypropyl solution 0.7.

Embodiment 3

[0060] A synthetic styrene-acrylic latex, the raw material of which has the following components by weight:

[0061] Acrylic 3

[0062] Isooctyl acrylate 6

[0063] Styrene 13

[0064] Butyl acrylate 7

[0065] Alkylphenol polyoxyethylene (10) ether 0.6

[0066] Ammonium persulfate 0.3

[0067] Ionized water 70

[0068] Dodecylbenzene sulfonic acid 0.3

[0069] Acrylamide 0.6

[0070] Diethanolamine 0.6

[0071]N-Hydroxypropyl solution 0.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com