Elastic emulsion for curing building putty and preparation method thereof

An elastic emulsion and putty technology, applied in the direction of filling slurry, etc., can solve the problem that construction putty cannot be solidified, and achieve good initial crack resistance and dynamic crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

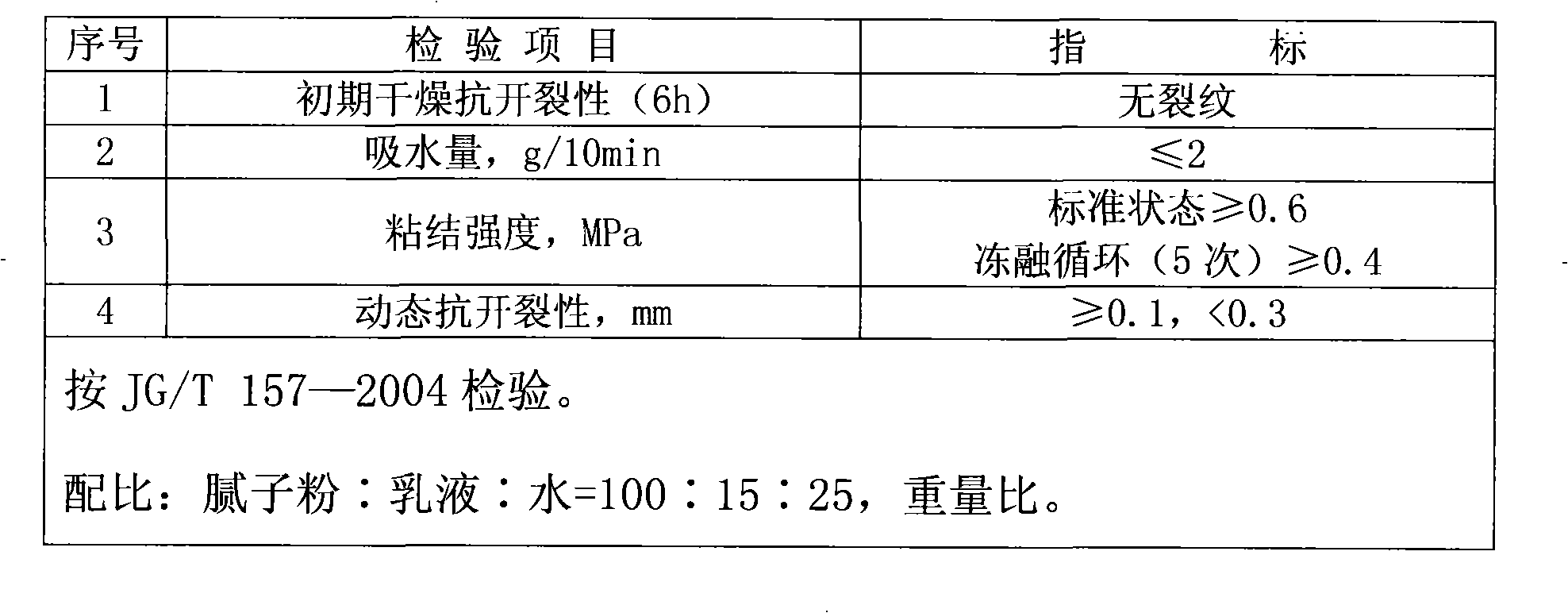

Image

Examples

Embodiment 1

[0047] formula:

[0048] Methyl methacrylate 90kg

[0049] Styrene 30kg

[0050] Butyl acrylate 81kg

[0051] Isooctyl acrylate 155kg

[0052] Acrylic 7kg

[0053] Co-436 1.3kg

[0054] Np-10 2kg

[0055] AMPS 2kg

[0056] Sodium bicarbonate 1.88kg

[0057] Ammonium persulfate 2.22kg

[0058] Sodium formaldehyde sulfoxylate 0.8kg

[0059] tert-butyl hydroperoxide 0.8kg

[0060] AMP-95 5.0kg

[0061] T-504 0.5kg

[0062] RM-8W 0.6kg

[0063] Deionized water 330kg

[0064] Aggregation method:

[0065] 1. Prefabricated components

[0066] ①Mix 140kg water, 0.5kg Co-436 and 2kg AMPS to obtain prefabricated components①;

[0067] ②Mix 20kg of water and 0.7kg of ammonium persulfate to obtain prefabricated components②;

[0068]③Mix 90kg of methyl methacrylate, 30kg of styrene, 81kg of butyl acrylate, 155kg of isooctyl acrylate and 7kg of acrylic acid to obtain prefabricated components③;

[0069] ④Mix 100kg of water, 0.8kg of C0-436, and 2kg of NP-10 to obtain prefabr...

Embodiment 2

[0081] formula:

[0082] Methyl methacrylate 100kg

[0083] Butyl acrylate 90kg

[0084] Isooctyl acrylate 165kg

[0085] Acrylic 11kg

[0086] Co-436 1.2kg

[0087] Np-10 0.6kg

[0088] AMPS 1.0kg

[0089] Sodium bicarbonate 2.2kg

[0090] Ammonium persulfate 2.2kg

[0091] Sodium formaldehyde sulfoxylate 1.2kg

[0092] tert-butyl hydroperoxide 1.2kg

[0093] AMP-95 4.0kg

[0094] T-504 1.2kg

[0095] RM-8W 1.2kg

[0096] Deionized water 350kg

[0097] Aggregation method:

[0098] 1. Prefabricated components

[0099] ①Mix 145kg of water, 0.5kg of Co-436 and 1kg of AMPS to obtain prefabricated components①;

[0100] ②Mix 25kg of water and 0.7kg of ammonium persulfate to obtain prefabricated components②;

[0101] ③Mix 100kg of methyl methacrylate, 90kg of butyl acrylate, 165kg of isooctyl acrylate and 11kg of acrylic acid to obtain prefabricated components③;

[0102] ④Mix 105kg of water, 0.7kg of C0-436, and 0.6kg of NP-10 to obtain prefabricated components④;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com