Biodegradable liquid mulch film produced from papermaking waste liquid, and production method thereof

A technology of papermaking waste liquid and liquid mulch, applied in chemical instruments and methods, fertilizer mixtures, organic fertilizers, etc., to achieve the effects of increasing water erosion resistance, eliminating white pollution, and improving drought resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

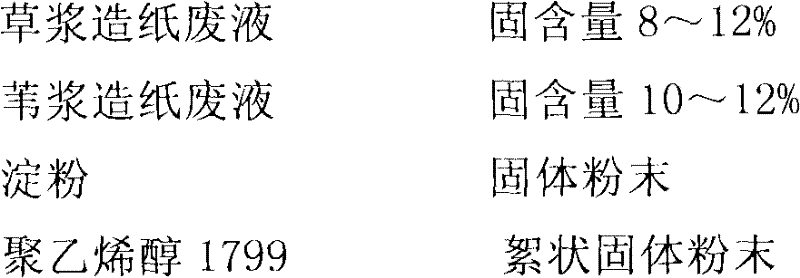

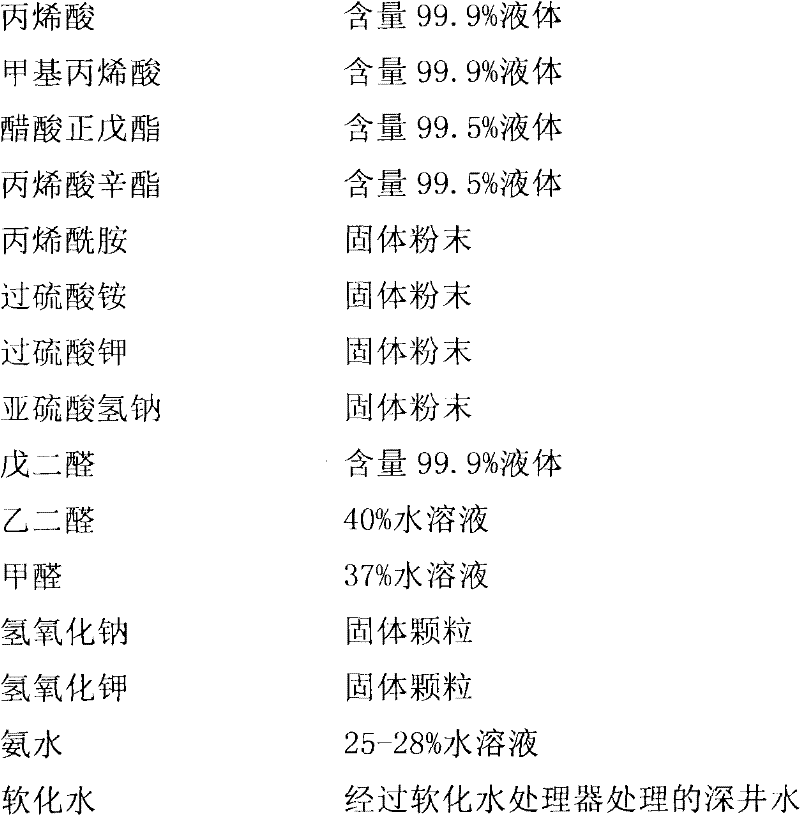

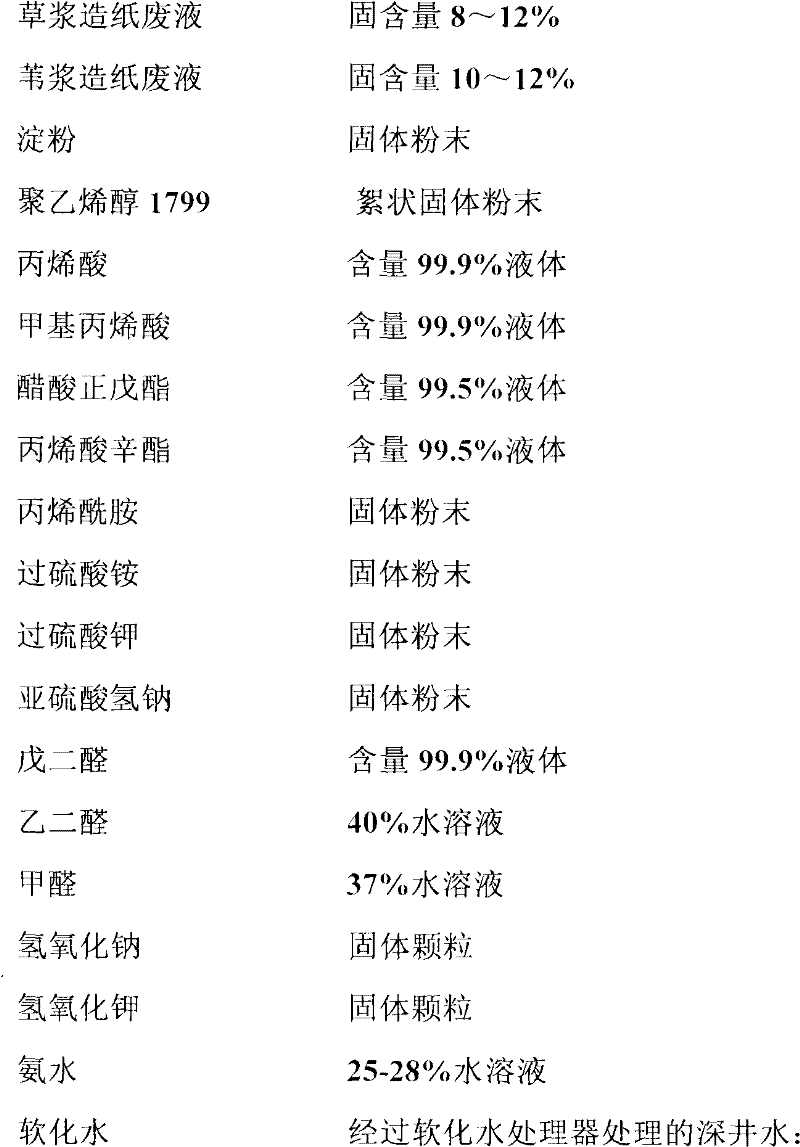

[0042] The mass distribution number of the present embodiment is as follows:

[0043] The main reaction base material is 8% (calculated on a dry basis of 100% solid content), the main reaction base material refers to straw pulp papermaking waste liquid, and what the straw pulp papermaking waste liquid used is wheat straw papermaking waste liquid with a solid content of 12%;

[0044] Other reaction base material is 8%, and other reaction base material refers to the mixture of 4% starch, 4% polyvinyl alcohol;

[0045] The graft modifier is 6%, and the graft modifier is a mixture of 4% acrylic acid, 1% octyl acrylate, and 1% acrylamide;

[0046] Initiator is 0.1%, and initiator is sodium bisulfite and potassium persulfate, and the ratio of sodium bisulfite and potassium persulfate is 1: 1;

[0047] The crosslinking agent is 0.25%, and the crosslinking agent is glutaraldehyde;

[0048] The neutralizing agent is 3% (on a dry basis of 100% solid content), and the neutralizing agent ...

Embodiment 2

[0056] The mass proportioning number of present embodiment is as follows:

[0057] The main reaction base material is 10% (calculated on a dry basis of 100% solid content), the main reaction base material refers to reed pulp papermaking waste liquid, and what the reed pulp papermaking waste liquid used is reed papermaking waste liquid with a solid content of 12%;

[0058] Other reaction base material is 6%, and other reaction base material refers to the mixture of 2% starch, 4% polyvinyl alcohol;

[0059] The graft modifier is 8%, and the graft modifier is a mixture of 6% acrylic acid and 2% octyl acrylate;

[0060] Initiator is 0.05%, and initiator is sodium bisulfite and potassium persulfate, and the ratio of sodium bisulfite and potassium persulfate is 1: 1;

[0061] The cross-linking agent is 0.5%, and the cross-linking agent is formaldehyde;

[0062] The neutralizing agent is 5% (on a dry basis of 100% solid content), and the neutralizing agent is potassium hydroxide; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com