Amphiphilic copolymer dispersant, preparation method and application

An amphiphilic copolymer and dispersant technology, applied in chemical instruments and methods, chemical/physical processes, transportation and packaging, etc., can solve problems such as weak adsorption on the surface of solid particles, aggregation or precipitation of solid particles, and increased production costs , to achieve the effect of rich product types, easy operation and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

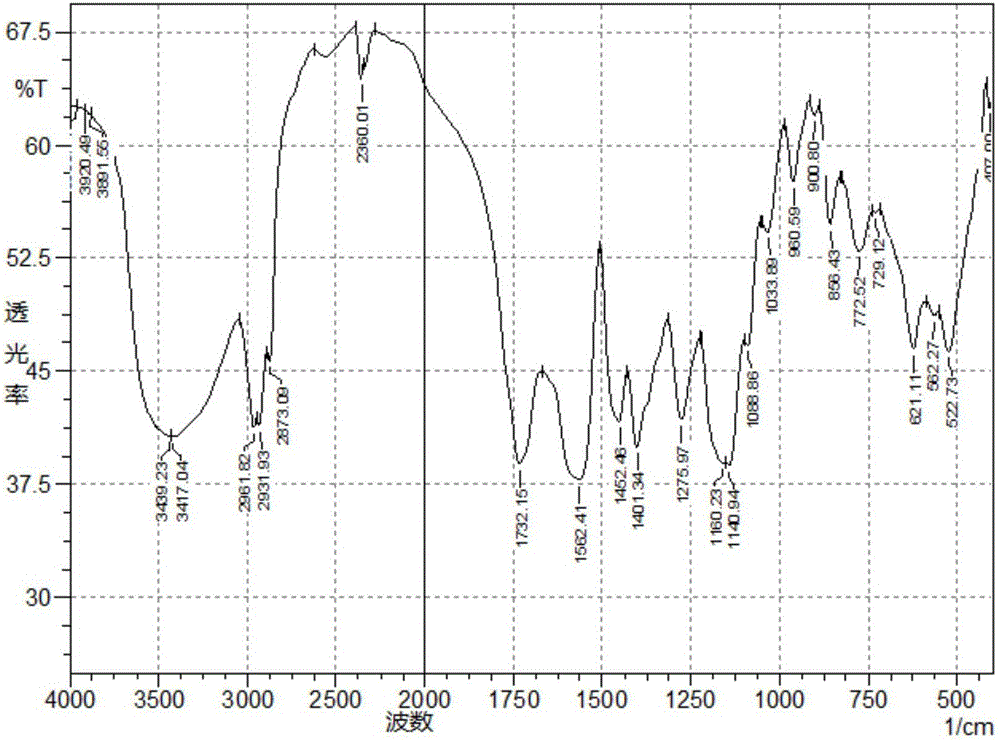

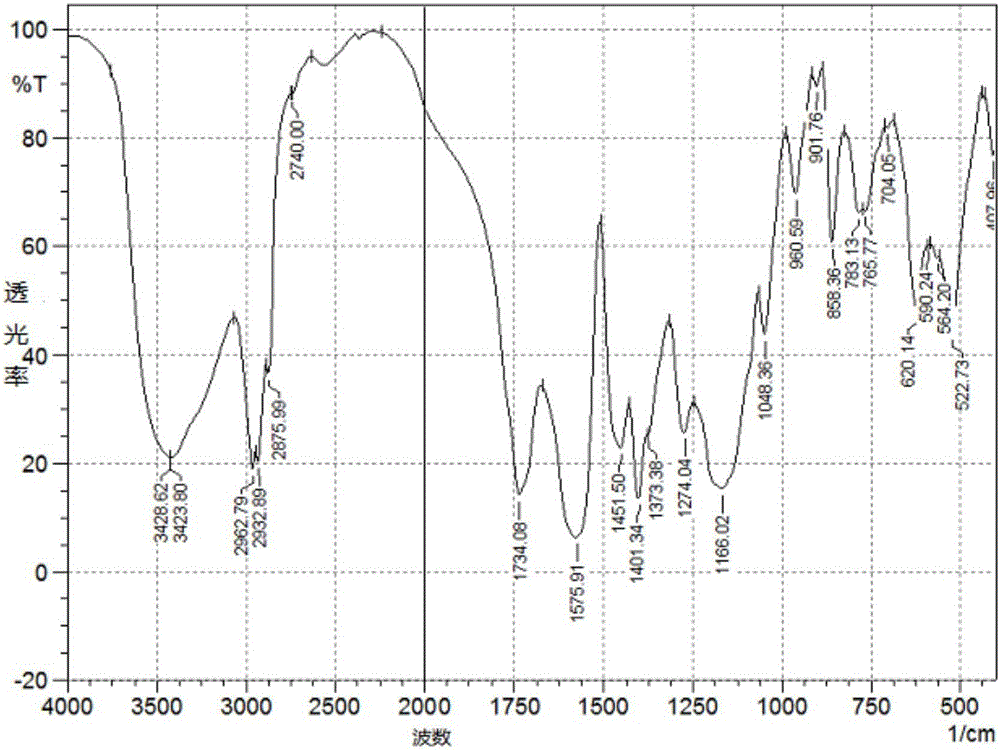

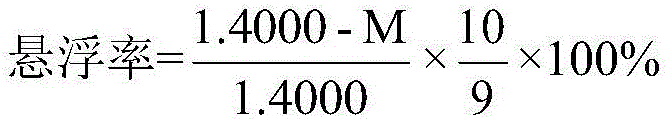

[0037] 1) Synthesis of methacrylic acid-isooctyl acrylate-hydroxyethyl acrylate copolymer

[0038] Put 220g 45% isopropanol aqueous solution into a 500mL four-necked flask with stirring, thermometer and reflux condenser, add 0.17g dodecanethiol and 0.80g polyvinyl alcohol, heat to reflux, reflux temperature is 82℃; add 59.8 g methacrylic acid, 10.6 g isooctyl acrylate, and 17.6 g hydroxyethyl acrylate are mixed uniformly to form a mixed monomer, 3.52 g sodium persulfate is dissolved in 84.0 g deionized water, and the initiator solution is mixed uniformly. At the reflux temperature, the above mixed monomer and initiator solution was added dropwise to the four-necked flask for 2 hours. After the addition, the reaction is continued for 2.5 hours. After the heat preservation, 122.0g of 20% sodium hydroxide solution is added dropwise, and the solvent is distilled off under reduced pressure to obtain a mixture of isopropanol and water. After the dealcoholization, the pH of the system i...

Embodiment 2

[0045] Put 220g of 50% isopropanol aqueous solution into a 500mL four-necked flask with stirring, thermometer and reflux condenser, add 0.17g of dodecanethiol and 0.80g of polyvinyl alcohol, and heat to reflux. The reflux temperature is 82℃; g methacrylic acid, 15.8 g isooctyl acrylate, and 19.4 g hydroxyethyl acrylate are mixed uniformly and made into a mixed monomer. Dissolve 3.60 g sodium persulfate in 84.0 g deionized water and mix well to make an initiator solution. At the reflux temperature, the above mixed monomer and initiator solution was added dropwise to the four-necked flask for 2 hours. After the addition, the reaction was continued for 2.5 hours. After the incubation, 107.7g of 20% sodium hydroxide solution was added dropwise, and the solvent was distilled off under reduced pressure to obtain a mixture of isopropanol and water. After the dealcoholization, the pH of the system was adjusted to 7~ 8. Add appropriate amount of water to adjust to a solid content of 35%...

Embodiment 3

[0048] In a 500mL four-necked flask with stirring, thermometer and reflux condenser, add 220g of 55% isopropanol aqueous solution, add 0.80g of polyvinyl alcohol, and heat to reflux. The reflux temperature is 82℃; 48.8g of methacrylic acid, 22.0 g Isooctyl acrylate and 17.6 g hydroxyethyl acrylate are mixed uniformly and made into a mixed monomer, 4.22g sodium persulfate is dissolved in 84.0g ionized water, mixed evenly to make an initiator solution, at the reflux temperature, The above-mentioned mixed monomer and initiator solution was added dropwise to the mouth flask, and the dropping time was 2h. After the addition, the reaction was continued for 2.5 hours. After the incubation, 99.8g of 20% sodium hydroxide solution was added dropwise, and the solvent was distilled off under reduced pressure to obtain a mixture of isopropanol and water. After the dealcoholization, the pH of the system was adjusted to 7~ 8. Add appropriate amount of water to adjust to a solid content of 35%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com