Pigment printing imitated reactive printing adhesive and preparation method thereof

A pigment printing and imitation activity technology, which is applied in the direction of adhesive type, ester copolymer adhesive, dyeing method, etc., can solve the problems that the production technology has not been reported, and the synthesis technology of pigment imitation activity printing adhesive is not involved. , to achieve the effect of improving adhesion fastness, good performance, and improving softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

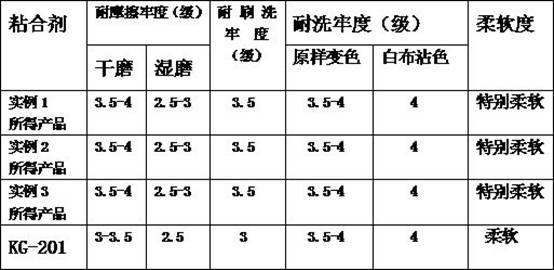

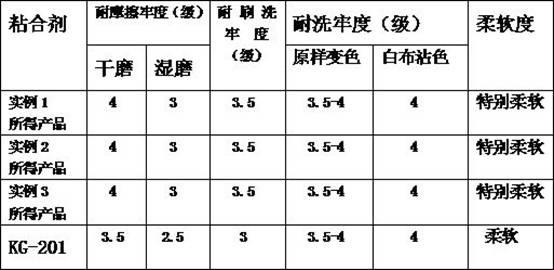

Examples

Embodiment 1

[0031] Raw material ratio: fatty alcohol polyoxyethylene ether (Pingping plus O-25) 5 . 8 g, sodium dodecylbenzene sulfonate 0 . 35 grams, butyl acrylate 25 grams, dimethylaminopropylmethacrylamide 1 . 1 g glycidyl methacrylate 4 . 3 grams, isooctyl acrylate 77 grams, methyl methacrylate 12 . 2 g, acrylic acid 3 . 5 g, ammonium persulfate 0 . 64 g, sodium bisulfite 0 . 32 grams, 146 grams of deionized water;

[0032] Process method:

[0033] 1) Add 25 grams of butyl acrylate and 1 dimethylaminopropyl methacrylamide to all monomers . 1 g, glycidyl methacrylate 4 . 3 grams, 77 grams of isooctyl acrylate, 12 grams of methyl methacrylate . 2 grams, acrylic acid 3 . Add 5 grams into the mixing tank and stir well;

[0034] 2) Add 44 grams of deionized water, fatty alcohol polyoxyethylene ether (Pingping plus O-25) 2 into the reaction kettle . 9 g and sodium dodecylbenzene sulfonate 0 . 12 grams, fully stirred to dissolve;

[0035] 3) Dissolving 0.64 grams of ammonium p...

Embodiment 2

[0043] Raw material ratio: fatty alcohol polyoxyethylene ether (Pingping plus O-25) 5 . 6 g, sodium dodecylbenzene sulfonate 0 . 4 g, butyl acrylate 26 g, dimethylaminopropylmethacrylamide 1 . 3 g, glycidyl methacrylate 4 .9 grams, isooctyl acrylate 75 grams, methyl methacrylate 12 . 5 g, acrylic acid 4 g, ammonium persulfate 0 . 7 g, sodium bisulfite 0 . 35 grams, 148 grams of deionized water;

[0044] Process method:

[0045] 1) Mix all the monomers, namely 26 grams of butyl acrylate, 1 dimethylaminopropyl methacrylamide . 3 grams, glycidyl methacrylate 4 . 9 grams, isooctyl acrylate 75 grams, methyl methacrylate 12 . Add 5 grams of acrylic acid and 4 grams of acrylic acid into the mixing kettle and stir thoroughly;

[0046] 2) Add 46 grams of deionized water, fatty alcohol polyoxyethylene ether (Pingping plus O-25) 2 into the reaction kettle . 5 g and sodium dodecylbenzene sulfonate 0 . 2 grams, fully stirred to dissolve;

[0047] 3) Dissolve 0.7 grams of ammoni...

Embodiment 3

[0055] Raw material ratio: fatty alcohol polyoxyethylene ether (Pingping plus O-25) 5 . 1 g, sodium dodecylbenzenesulfonate 0 . 47 grams, butyl acrylate 28 grams, dimethylaminopropylmethacrylamide 1 . 4 g, glycidyl methacrylate 4 . 5 grams, isooctyl acrylate 76 grams, methyl methacrylate 12 . 8 grams, acrylic acid 4 . 3 g, ammonium persulfate 0 . 78 g, sodium bisulfite 0 . 39 grams, 150 grams of deionized water;

[0056] Process method:

[0057] 1) Mix all the monomers, 28 grams of butyl acrylate, 1 dimethylaminopropyl methacrylamide . 4 grams, glycidyl methacrylate 4 . 5 grams, isooctyl acrylate 76 grams, methyl methacrylate 12 . 8 grams, acrylic acid 4 . Add 3 grams into the mixing tank and stir thoroughly;

[0058] 2) Add 47 grams of deionized water, fatty alcohol polyoxyethylene ether (Pingping plus O-25) into the reaction kettle . 7 g and sodium dodecylbenzene sulfonate 0 . 16 grams, fully stirred to dissolve;

[0059] 3) Dissolving 0.78 grams of ammonium pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com