Special-purpose acrylic glue of lithium battery and preparation method thereof

An acrylic glue, lithium battery technology, applied in the direction of adhesives, conjugated diene adhesives, adhesive types, etc., can solve the problems of reduced adhesion, shortened battery life, safety hazards, etc., to achieve good viscosity, The effect of prolonging service life and eliminating safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

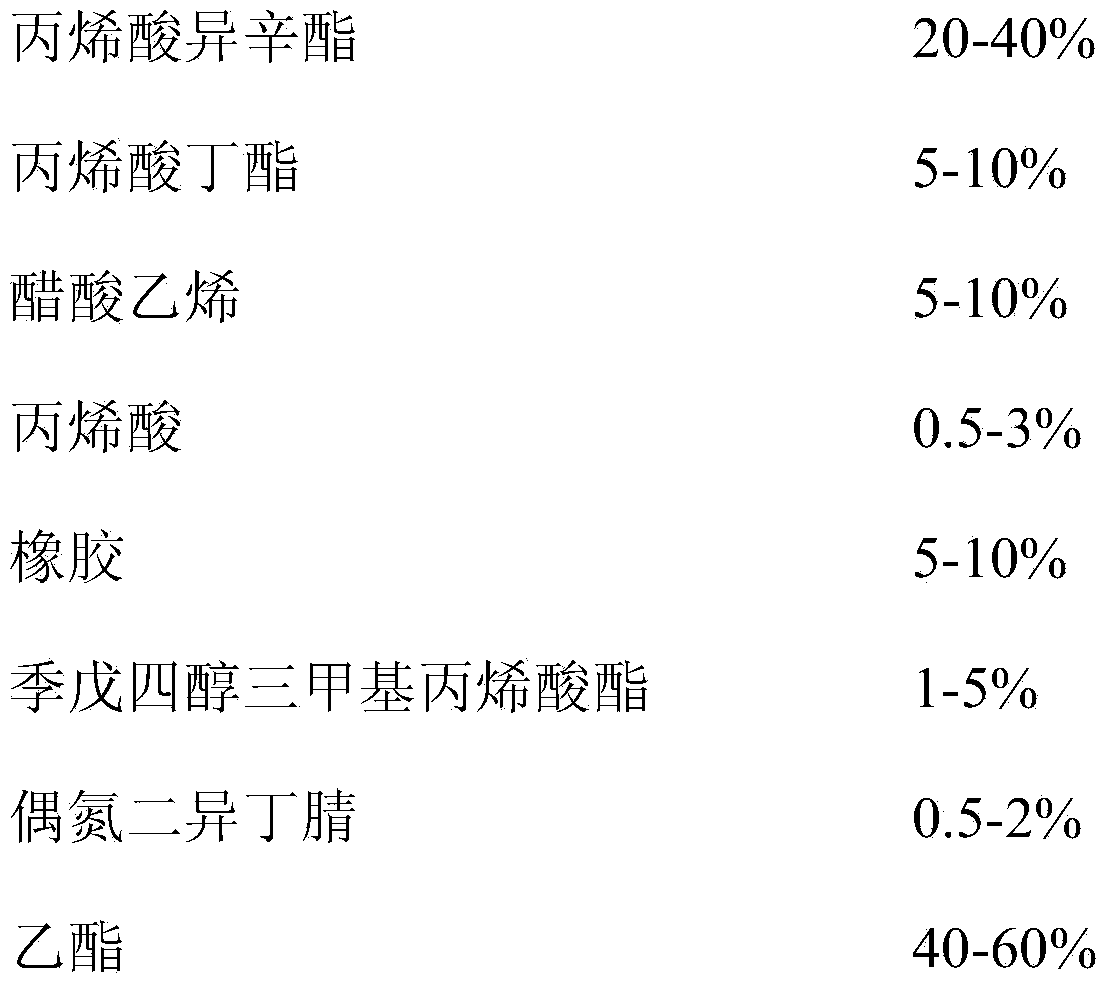

[0034] A special acrylic glue for lithium batteries, including the following raw materials in weight percentage:

[0035]

[0036] Wherein, the rubber is butadiene rubber.

[0037] A preparation method of special acrylic glue for lithium battery includes the following steps:

[0038] Step A. Put isooctyl acrylate, butyl acrylate, vinyl acetate, acrylic acid, and ethyl ester into the reaction kettle at one time according to the formula, and add two-thirds of the volume of the reaction kettle. Start stirring continuously and heat to the material temperature. 70°C, the stirring speed is 120r / min; wherein the amount of the ethyl ester is 40% of the total weight of the ethyl ester; Step B, stir and mix pentaerythritol trimethacrylate, azobisisobutyronitrile and the remaining ethyl ester evenly Then add the dripping tank; wherein the amount of azobisisobutyronitrile is 60% of the total weight of azobisisobutyronitrile; step C, drop the materials in the dripping tank of step B into the rea...

Embodiment 2

[0042] A special acrylic glue for lithium batteries, including the following raw materials in weight percentage:

[0043]

[0044]

[0045] Wherein, the rubber is ethylene propylene rubber.

[0046] A preparation method of special acrylic glue for lithium battery includes the following steps:

[0047] Step A. Put isooctyl acrylate, butyl acrylate, vinyl acetate, acrylic acid, and ethyl ester into the reaction kettle at one time according to the formula, and add two-thirds of the volume of the reaction kettle. Start stirring continuously and heat to the material temperature. 75°C, the stirring speed is 110r / min; wherein the amount of the ethyl ester is 50% of the total weight of the ethyl ester; Step B, stir and mix the pentaerythritol trimethacrylate, azobisisobutyronitrile and the remaining ethyl ester evenly Then add the dripping tank; wherein, the amount of azobisisobutyronitrile is 70% of the total weight of azobisisobutyronitrile; step C, drop the materials in the dripping tank...

Embodiment 3

[0051] A special acrylic glue for lithium batteries, including the following raw materials in weight percentage:

[0052]

[0053] Wherein, the rubber is styrene butadiene rubber.

[0054] A preparation method of special acrylic glue for lithium battery includes the following steps:

[0055] Step A. Put isooctyl acrylate, butyl acrylate, vinyl acetate, acrylic acid, and ethyl ester into the reaction kettle at one time according to the formula, and add two-thirds of the volume of the reaction kettle. Start stirring continuously and heat to the material temperature. 78°C, the stirring speed is 100r / min; wherein the amount of the ethyl ester is 55% of the total weight of the ethyl ester; Step B, stir and mix pentaerythritol trimethacrylate, azobisisobutyronitrile and the remaining ethyl ester evenly Then add the dripping tank; wherein the amount of azobisisobutyronitrile is 75% of the total weight of azobisisobutyronitrile; step C, drop the materials in the dripping tank of step B into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com