Low-emulsion-addition and high-scrubbing-resistance water-based interior wall emulsion and preparation thereof

A water-based emulsion, the technology of adding amount, applied in the direction of latex paint, coating, etc., can solve the problems of pollution, affecting flexibility, etc., and achieve the effect of uniform dispersion, improved scrub resistance and excellent scrub resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] a. Preparation of pre-emulsion: add 45% deionized water and 28% emulsifier, turn on the agitator, and turn on the agitator at 300 Hz, and drop in styrene, butyl acrylate, isooctyl acrylate, and alkyl carboxylic acid successively Cross-linking monomer, siloxane, organic oil and persulfate, continue stirring for 30 minutes;

[0039] b. Add the remaining deionized water and emulsifier into another reactor, stir evenly, and raise the temperature to 85°C; put in 20% pre-emulsion, and stir for 20 minutes;

[0040] c. Continuously and evenly drop the remaining pre-emulsion, keep the heat at 85-87°C, add dropwise for 4 hours, and keep warm for 30 minutes after the dropwise addition;

[0041] (2) Post-processing stage

[0042] a. Cool down to below 50°C;

[0043] b. After the temperature of the emulsion drops to room temperature, filter and pack.

Embodiment 1

[0045] Embodiment 1 a kind of acrylate emulsion

[0046] The acrylate emulsion is prepared from the following raw materials in parts by weight:

[0047] 25 parts of styrene, 8 parts of butyl acrylate, 8 parts of isooctyl acrylate, 2.5 parts of alkyl carboxylic acid crosslinking monomer, 1 part of siloxane, 1.5 parts of organic oil, 1.7 parts of emulsifier, 0.3 parts of persulfate With 52 parts of water;

[0048] Described alkyl carboxylic acid cross-linking monomer is 1 part of itaconic acid, 1.5 parts of acrylic acid;

[0049] Described siloxane is vinyltrimethoxysilane;

[0050] Described organic matter oil is epoxidized soybean oil;

[0051] Described emulsifier is 1.2 parts of sodium dodecyl diphenyl oxide disulfonate, 0.5 part of potassium lauryl polyoxyethylene ether sulfate;

[0052] Described persulfate is potassium persulfate;

[0053] The preparation method of the acrylate emulsion comprises the following steps:

[0054] (1) Synthesis stage

[0055] a. Prepara...

Embodiment 2

[0062] Embodiment 2 a kind of acrylate emulsion

[0063] The acrylate emulsion is prepared from the following raw materials in parts by weight:

[0064] 25 parts of styrene, 10 parts of butyl acrylate, 6.2 parts of isooctyl acrylate, 2.5 parts of alkyl carboxylic acid crosslinking monomer, 1.5 parts of siloxane, 1 part of organic oil, 1.5 parts of emulsifier, 0.3 parts of persulfate With 53 parts of water;

[0065] Described alkyl carboxylic acid cross-linking monomer is acrylic acid;

[0066] Described siloxane is vinyltriethoxysilane;

[0067] Described organic matter oil is tung oil;

[0068] Described emulsifier is potassium dodecyl diphenyl oxide disulfonate;

[0069] Described persulfate is ammonium persulfate;

[0070] Its preparation method is identical with embodiment 1.

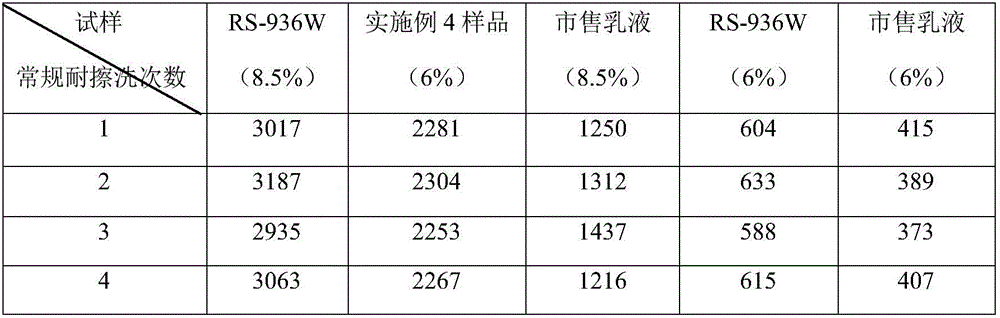

[0071] Through the scrub resistance test, the latex paint with 6% emulsion addition amount prepared by the interior wall emulsion of the present invention can reach 2450 times of scrub resista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com