High cold-resistance ultra-high impact strength resistance modified for PVC

An impact modifier and impact strength technology, which is applied in the field of impact modifiers for polyvinyl chloride, can solve the problems of high processing costs of PVC products, and achieve the effect of improving impact strength and ultra-high impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

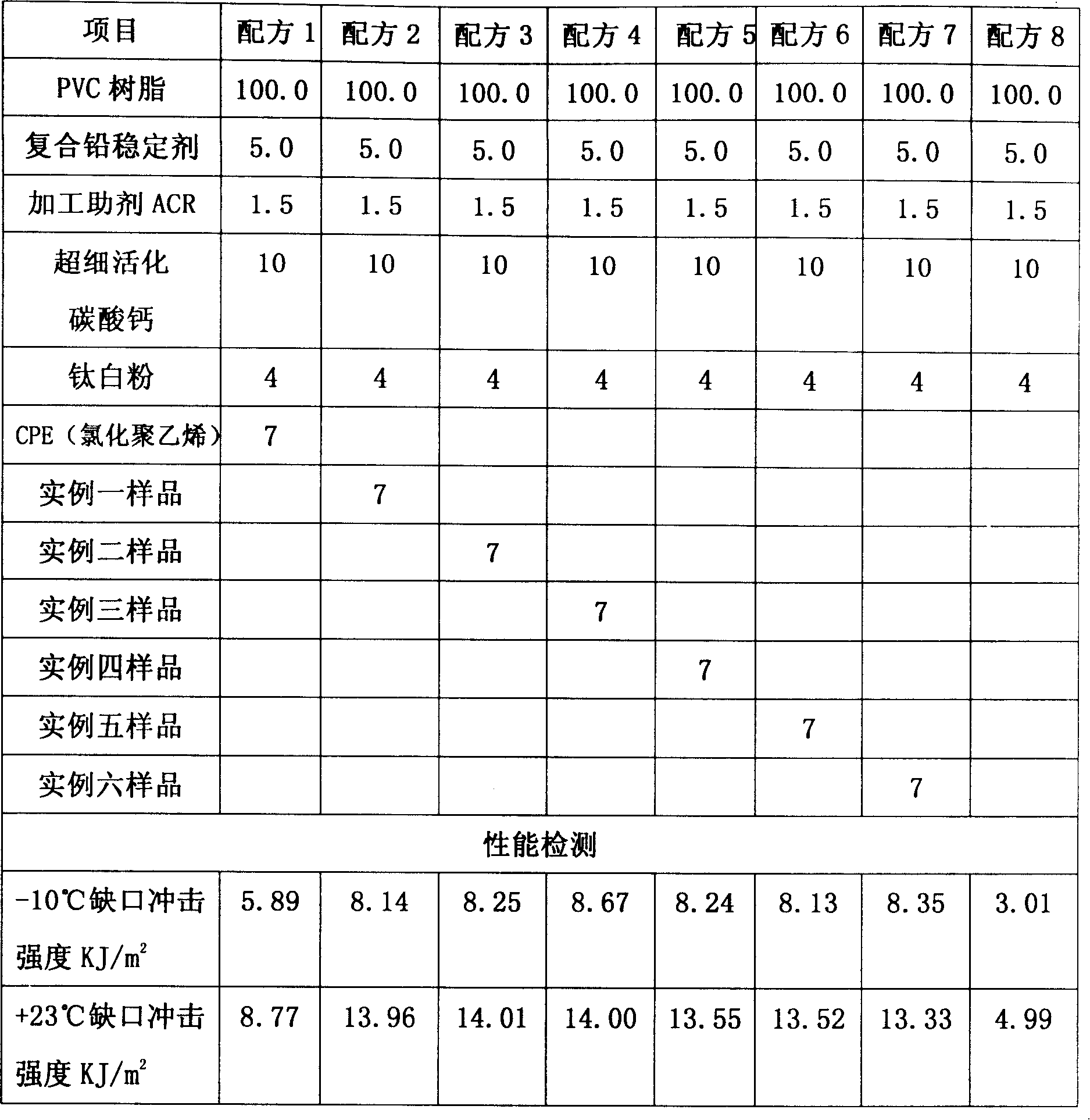

Examples

example 1

[0012] Example 1: Add deionized water in a 3000L glass-lined kettle, which is 49% of the total emulsion, 1% (accounting for the total amount of polymerized monomers) of sodium lauryl sulfate, stir, add butyl acrylate, acrylic acid Isooctyl acrylate and crosslinking agent ethylene glycol dimethacrylate, based on the amount of butyl acrylate and isooctyl acrylate as 100%, butyl acrylate is 50%, isooctyl acrylate is 50%, dimethyl Ethylene glycol acrylate is 1% of the total amount of the two polymerized monomers of the core layer, adding potassium persulfate which is 0.01% of the total polymerized monomer amount of the core layer and the shell layer, and the polymerized monomers are evenly divided into 4 sections for emulsion polymerization. After the measured conversion rate is greater than 95%, the next stage of polymerization monomer is added, and the reaction temperature is controlled to 50-80°C. After the exotherm is complete, keep the temperature at 80-85°C for 1 hour. Cont...

example 2

[0013] Example 2: Same as Example 1, except that the amount of polymerized monomers in the shell layer is 8% of the total amount of polymerized monomers, and the amount of polymerized monomers in the core layer accounts for 92% of the total amount of polymerized monomers.

example 3

[0014] Example 3: Same as Example 1, except that the amount of polymerized monomers in the shell layer is 6% of the total amount of polymerized monomers, and the amount of polymerized monomers in the core layer accounts for 94% of the total amount of polymerized monomers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com