Preparation method of optical transparent two-sided sticky tape

A double-sided tape, optically transparent technology, used in chemical instruments and methods, adhesives, film/flake adhesives, etc., can solve the yellowing of OCA optical tape products, affect the quality of touch screens, and it is difficult to make thick films. and other problems, to avoid oxidative discoloration, improve visibility, and achieve the effect of excellent light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

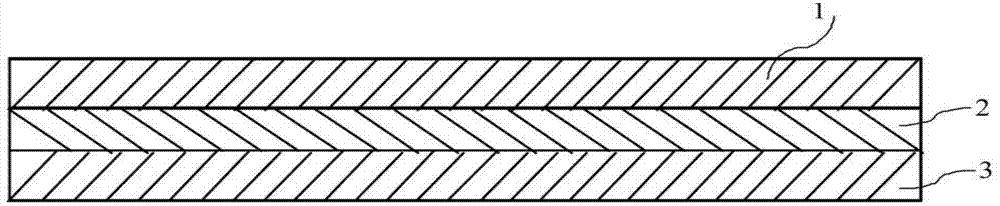

Image

Examples

Embodiment 1

[0033] ●Preparation of acrylate prepolymerized resin

[0034] At room temperature, mix 30kg butyl acrylate, 15kg isooctyl acrylate, 30kg ethyl methacrylate, 20kg methoxyethyl acrylate, 5kg glycidyl methacrylate, 100kg solvent (ethyl acetate: butanone=1:1) , and 0.3kg of benzoyl peroxide were added to a reaction kettle with a condensing reflux device, stirred at a rotation speed of 200rpm, and mixed evenly; under the protection of nitrogen, the temperature was gradually raised to 75°C, reacted for 4h, and stopped heating. Then add 50.45kg of solvent (ethyl acetate: butanone = 1:1) and mix evenly, cool to room temperature and discharge to prepare acrylate prepolymer resin (1) for later use. The solid content after drying at 90°C 40%.

[0035] ●Preparation of acrylate optical glue

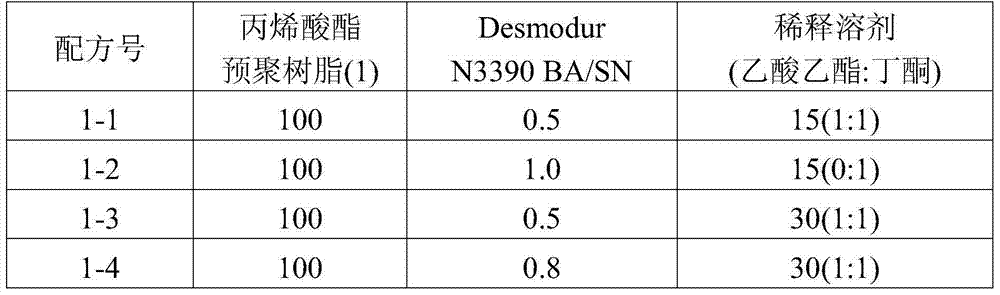

[0036] (1) Formula (unit: kg)

[0037]

[0038] (2) Preparation process

[0039] Add the acrylate prepolymerized resin (1) in the above formula into the mixing tank, start stirring at a speed o...

Embodiment 2

[0041] ●Preparation of acrylate prepolymerized resin

[0042]At room temperature, mix 20kg butyl acrylate, 10kg isooctyl acrylate, 25kg ethyl methacrylate, 30kg methoxyethyl acrylate, 15kg glycidyl methacrylate, 100kg solvent (ethyl acetate: butanone=1:1) , and 0.5kg of benzoyl peroxide were added to the reaction kettle with a condensing reflux device, so that the temperature of the condenser was controlled at 20±5°C, stirred at a rotation speed of 200rpm, and mixed evenly; under the protection of nitrogen, the temperature was gradually raised to 70°C , Reaction 4h, stop heating. Then add 50.75kg of solvent (ethyl acetate: butanone = 1:1) and mix evenly, cool to room temperature and discharge to prepare acrylate prepolymer resin (2) for later use. The solid content after drying at 90°C 40%.

[0043] ●Preparation of acrylate optical glue

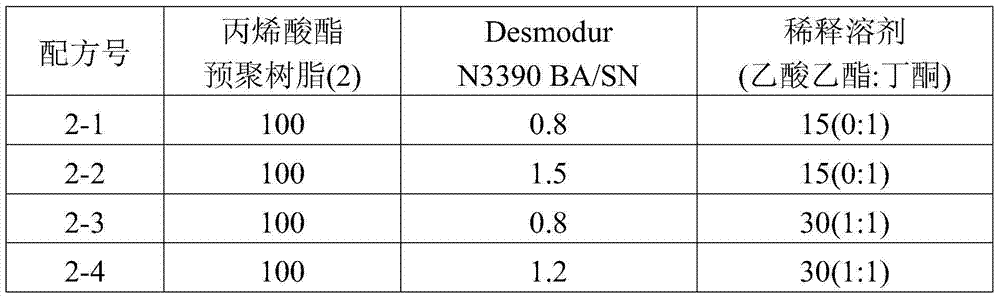

[0044] (1) Formula (unit: kg)

[0045]

[0046] (2) Preparation process

[0047] Add the acrylate prepolymerized resin (2) of the ab...

Embodiment 3

[0049] ●Preparation of acrylate prepolymerized resin

[0050] At room temperature, mix 30kg butyl acrylate, 10kg isooctyl acrylate, 30kg ethyl methacrylate, 20kg methoxyethyl acrylate, 10kg glycidyl methacrylate, 100kg solvent (ethyl acetate: butanone=1:1) , and 0.5kg of azobisbutyronitrile were added to a reaction kettle with a condensing reflux device, stirred at a rotation speed of 200rpm, and mixed uniformly; under the protection of nitrogen, the temperature was gradually raised to 75°C, reacted for 4h, and stopped heating. Then add 50.75kg of solvent (ethyl acetate: butanone = 1:1) and mix evenly, cool to room temperature and discharge to prepare acrylate prepolymer resin (3) for later use. The solid content after drying at 90°C 40%.

[0051] ●Preparation of acrylate optical glue

[0052] (1) Formula (unit: kg)

[0053]

[0054] (2) Preparation process

[0055] Add the acrylate prepolymerized resin (3) in the above formula into the mixing tank, start stirring at a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com