Modified white latex and preparation method thereof

A white latex, modification technology, applied in the direction of monocarboxylate copolymer adhesives, adhesive types, etc., can solve the problems of limiting the use of white latex, reduced bonding strength, poor water resistance, etc., to improve water resistance Performance and adhesive performance, improvement of construction performance, and the effect of preventing gelation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

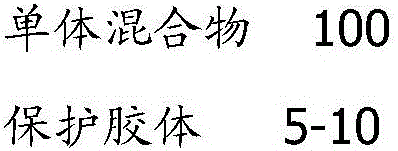

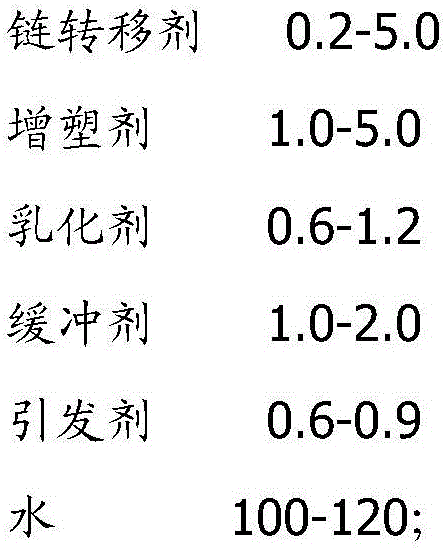

[0038] Embodiment 1 of the present application modified white latex includes the following raw materials in parts by weight (based on monomer mixture quality 100):

[0039] Monomer mixture 100 (wherein the amount of vinyl acetate accounts for 80% of the monomer mixture, 1% of acrylic acid, 14% of isooctyl acrylate, 5% of vinyl tertiary carbonate)

[0040]

[0041] All components involved in Example 1 of the present application can be obtained through public commercial channels.

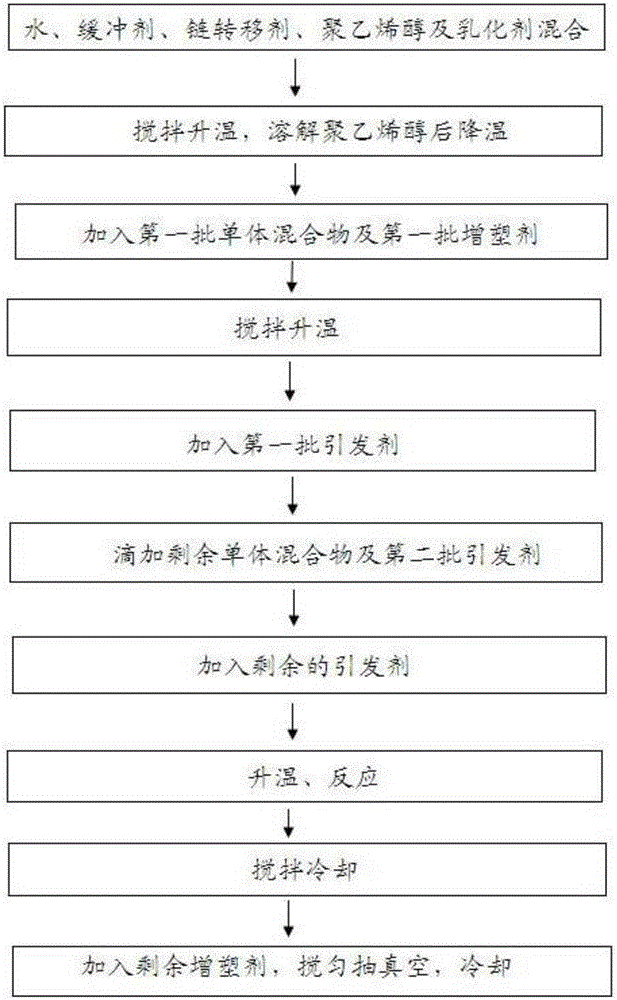

[0042] The application embodiment 1 modified white latex preparation process such as figure 1 shown, including the following specific steps:

[0043] Add water, buffer, chain transfer agent, polyvinyl alcohol and emulsifier into the three-necked flask, heat up to 88°C under constant stirring, keep this temperature until the polyvinyl alcohol is completely dissolved, then cool down to 60°C to prevent the temperature from being too high Initiate implosion; add 1 / 10 of the total amount of the monome...

Embodiment 2

[0045] The application embodiment 2 modified white latex comprises the raw material of following weight portion (based on monomer mixture quality 100):

[0046] Monomer mixture 100 (wherein the amount of vinyl acetate accounts for 90% of the monomer mixture, 1% of acrylic acid, 4% of isooctyl acrylate, 5% of vinyl tertiary carbonate)

[0047]

[0048] All components involved in Example 2 of the present application can be obtained through public commercial channels.

[0049] The preparation process of the application embodiment 2 modified white latex is as follows:

[0050] Add water, buffer, chain transfer agent, polyvinyl alcohol and emulsifier into the three-necked flask, heat up to 90°C under constant stirring, keep this temperature until the polyvinyl alcohol is completely dissolved, then cool down to 60°C; add to the three-necked flask 1 / 10 of the total amount of the monomer mixture and 1 / 2 of the total amount of the plasticizer, stir evenly; raise the temperature of ...

Embodiment 3

[0052] Embodiment 3 of the present application modified white latex includes the following raw materials in parts by weight (based on monomer mixture quality 100):

[0053] Monomer mixture 100 (wherein the amount of vinyl acetate accounts for 95% of the monomer mixture, 3% of isooctyl acrylate, 2% of vinyl tertiary carbonate)

[0054]

[0055] All components involved in Example 3 of the present application can be obtained through public commercial channels.

[0056] The preparation process is as follows:

[0057] Add water, buffer, chain transfer agent, polyvinyl alcohol and emulsifier into the three-necked flask, raise the temperature to 92°C under constant stirring, keep this temperature until the polyvinyl alcohol is completely dissolved, then cool down to 60°C; add to the three-necked flask 1 / 10 of the total amount of the monomer mixture and 1 / 2 of the total amount of the plasticizer, stir evenly; raise the temperature of the reactor to 75°C, stir for 1.0 hour, then ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com