Hydrophobic associated polymer modified magnetic nano-thickener and preparation method thereof

A hydrophobic association and polymer technology, applied in drilling compositions, chemical instruments and methods, and earthwork drilling, etc., can solve the problems of insufficient high temperature resistance and salt resistance, and reduce the difficulty of operation and production cost. The effect of shear resistance and fluid loss resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Nano Fe 3 o 4 Surface Oleic Acid Modification

[0030] At room temperature, 11.5g (49.7mmol) of nano Fe 3 o 4 Add 7.0g (24.8mmol) oleic acid into 100mL deionized water, mechanically stir (stirring rate 300rpm) for 90 minutes, then add ammonia water with a mass fraction of 25% to adjust the pH value to 10-11, continue mechanically stirring for 12 hours; the reaction is completed The final suspension was centrifuged (centrifugal speed 2000rpm) for 30 minutes, and the obtained precipitate was washed 3 times with a mixture of absolute ethanol and deionized water with a volume ratio of 1:1, and vacuum-dried at 60°C for 24 hours to obtain Oleic acid modified nano Fe 3 o 4 . The reaction yield was about 70%.

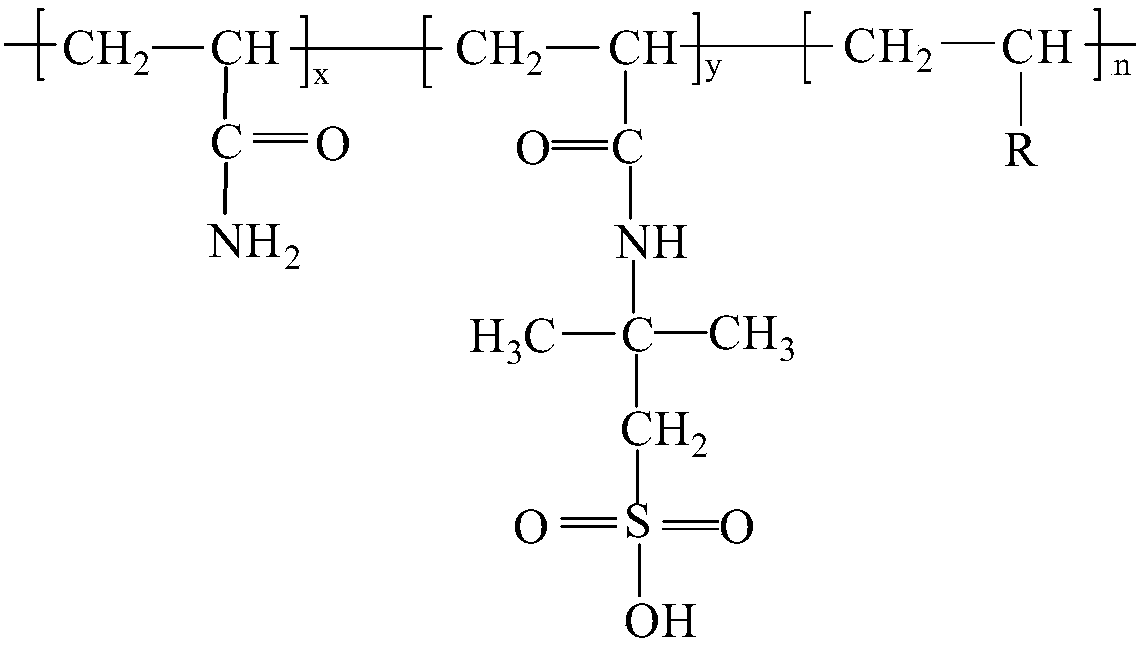

[0031] 2. Grafted AM / AMPS / styrene terpolymer

[0032] Dissolve 6.5g (91.4mmol) of acrylamide (AM) and 2.2g (10.6mmol) of 2-acrylamido-2-methylpropanesulfonic acid (AMPS) in 90mL of deionized water, and then oxidize it with hydrogen Sodium adjusts pH value to 8~...

Embodiment 2

[0041] 1. Nano Fe 3 o 4 Surface Undecylenic Acid Modification

[0042] At room temperature, 11.5g (49.7mmol) of nano Fe 3 o 4 and 2.8g (15.2mmol) undecylenic acid were added into 100mL deionized water, ultrasonicated for 15 minutes, then adding mass fraction of 25% ammonia water to adjust the pH value to 10-11, and continued ultrasonication for 3 hours; the suspension after the reaction was completed Centrifugal separation (centrifugal speed 2000rpm) for 30 minutes, the obtained precipitate was washed 3 times with a mixture of absolute ethanol and deionized water with a volume ratio of 1:1, and vacuum-dried at 60°C for 24 hours to obtain undecylenic acid modified Nano Fe 3 o 4 . The reaction yield was about 65%.

[0043] 2. Grafted AM / AMPS / acrylic n-octyl terpolymer

[0044] Dissolve 6.0g (84.4mmol) of acrylamide (AM) and 2.5g (12.1mmol) of 2-acrylamido-2-methylpropanesulfonic acid (AMPS) in 90mL of deionized water. Sodium adjusts the pH value to 8-9; then the mixed s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com