Aqueous crackle paint and coating technology thereof

A water-based technology of leather texture paint, applied in the field of paint, can solve the problems of difficult realization of leather texture paint water-based, inability to adapt to assembly line operations, slow volatilization speed of water-based paint, etc., achieve average crack and crack size, good step volatilization rate, The effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: a kind of water-based leather texture paint, this water-based leather texture paint is made by, water-based leather texture primer, water-based leather texture finish paint and water-based enamel enamel paint make according to coating process.

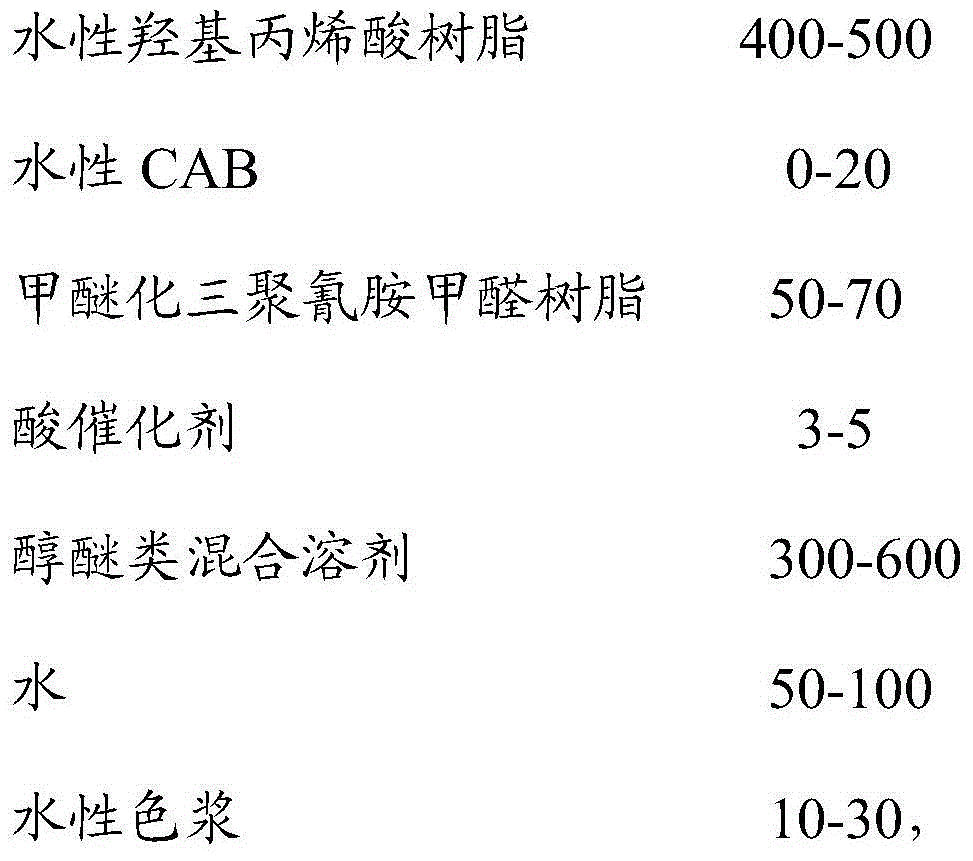

[0032] Described water-based texture primer, by weight, comprises the following components:

[0033]

[0034] Add water-based hydroxyl acrylic resin, water-based CAB, methyl etherified melamine formaldehyde resin, acid catalyst, alcohol ether mixed solvent, water, water-based color paste into the container in turn, mix and stir evenly to prepare water-based skin texture primer.

[0035] The water-based color paste is: water-based carbon black paste.

[0036] Described water-based leather finish paint, by weight, comprises following component:

[0037]

[0038]

[0039] Add water-based hydroxyacrylic resin, water-based CAB, methyl etherified melamine formaldehyde resin, acid catalyst, alcohol-ether mixed s...

Embodiment 2

[0055] A water-based leather-textured paint is prepared by a water-based leather-textured primer, a water-based leather-textured topcoat and a water-based enamel enamel according to a coating process.

[0056]Further, the water-based skin texture primer includes the following components in parts by weight:

[0057]

[0058]

[0059] Add water-based hydroxyl acrylic resin, water-based CAB, methyl etherified melamine formaldehyde resin, acid catalyst, alcohol ether mixed solvent, water, water-based color paste into the container in turn, mix and stir evenly to prepare water-based skin texture primer.

[0060] The water-based color paste is an equal proportion mixture of water-based iron oxide red paste and water-based iron oxide yellow paste.

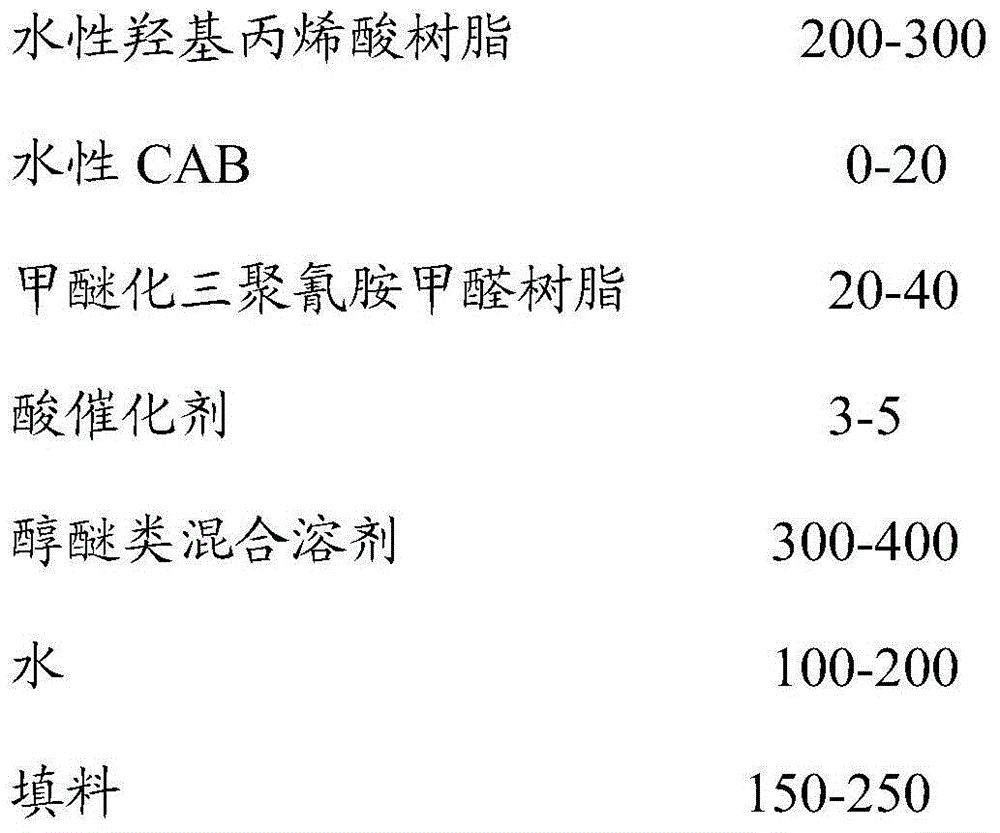

[0061] Described water-based leather finish paint, by weight, comprises following component:

[0062]

[0063] Add water-based hydroxyacrylic resin, water-based CAB, methyl etherified melamine formaldehyde resin, acid catalyst, ...

Embodiment 3

[0079] A water-based leather-textured paint is prepared by a water-based leather-textured primer, a water-based leather-textured topcoat and a water-based enamel enamel according to a coating process.

[0080] Further, the water-based skin texture primer includes the following components in parts by weight:

[0081]

[0082] Add water-based hydroxyl acrylic resin, water-based CAB, methyl etherified melamine formaldehyde resin, acid catalyst, alcohol ether mixed solvent, water, water-based color paste into the container in turn, mix and stir evenly to prepare water-based skin texture primer.

[0083] The water-based color paste is water-based iron oxide yellow paste.

[0084] Described water-based leather finish paint, by weight, comprises following component:

[0085]

[0086]

[0087] Add water-based hydroxyacrylic resin, water-based CAB, methyl etherified melamine formaldehyde resin, acid catalyst, alcohol-ether mixed solvent, water, filler, and toning pigment into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com