Waterborne bi-component coal tar pitch anticorrosive paint and preparation method thereof

A technology of anti-corrosion coatings and coal tar pitch, applied in anti-corrosion coatings, asphalt coatings, anti-fouling/underwater coatings, etc., can solve the problems of poor film-forming performance during construction, and achieve good chemical resistance, strong adhesion, The effect of low VOC

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

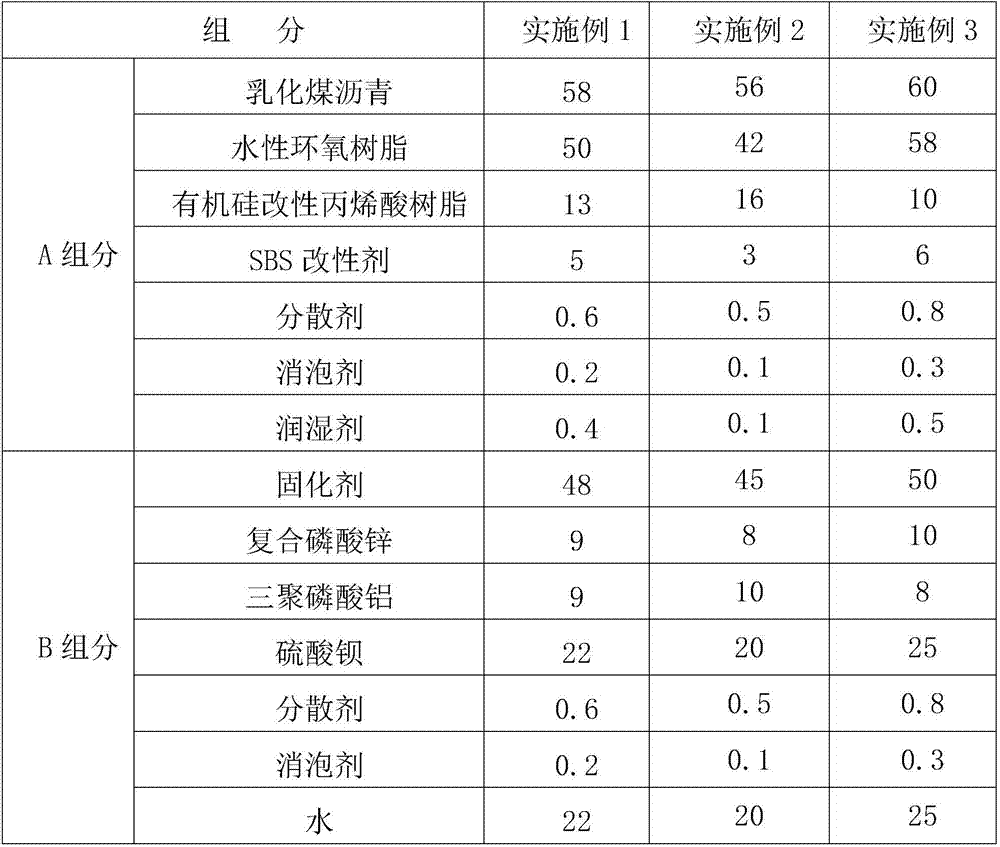

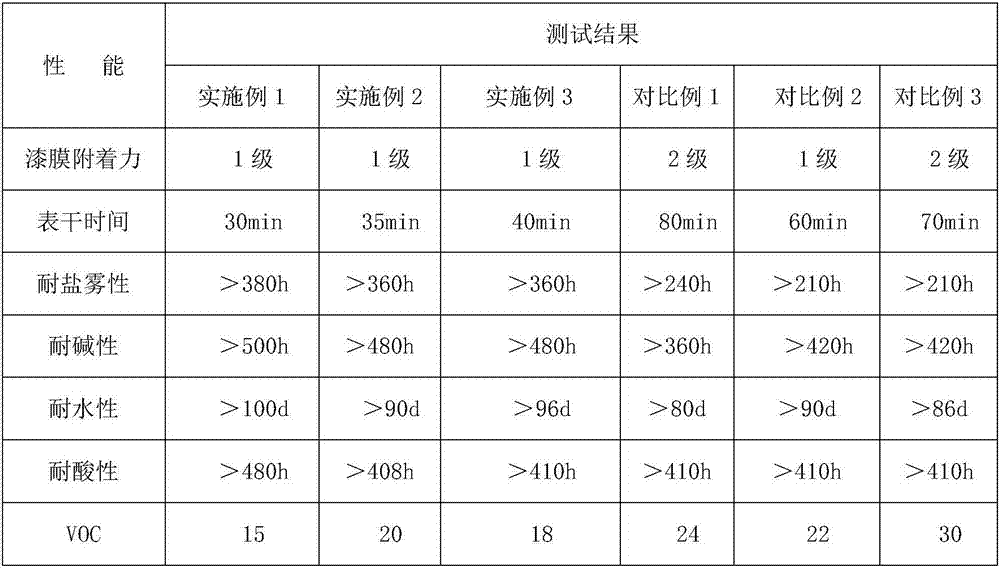

Examples

Embodiment

[0038] Preparation of component A:

[0039] Step a1, adding SBS modifier to emulsified coal tar pitch (50% solid content), dispersing at 600-900rpm for 10-15min;

[0040] Step a2, add water-based epoxy resin emulsion (solid content is 45%), silicone modified acrylic resin, defoamer, dispersant and wetting agent successively to the mixture obtained in step a1, continue to stir for 10-15min, and then Disperse at 600-900rpm for 10-15min to obtain component A;

[0041] Preparation of component B:

[0042] Step b1, mixing the curing agent, composite zinc phosphate, aluminum tripolyphosphate, barium sulfate, dispersant, 0.1-0.3 parts of defoamer and water, and dispersing at 300-500 rpm for 30-40 minutes to form a uniform paint slurry;

[0043] Step b2, grinding the uniform paint slurry to a fineness of ≤75 μm and filtering it with a 200-mesh filter to obtain component B;

[0044] Among them, the A component and the B component are mixed according to the mass ratio of 5:1.

[0045]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com