Water-based epoxy floor paint emulsion and preparation method thereof

A technology of epoxy floor paint and emulsion, which is applied in the direction of coating, etc., can solve the problems of easy precipitation and layering, poor stability of water-based epoxy emulsion, etc., achieve strong adhesion, excellent chemical resistance, and improve physical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

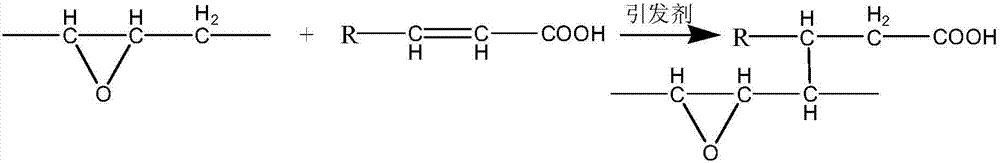

Method used

Image

Examples

Embodiment 1

[0034] Accurately weigh the following raw materials by weight: 100 parts of E-41 epoxy resin, 10 parts of methacrylic acid, 5 parts of hydroxyethyl methacrylate, 15 parts of butyl acrylate, 20 parts of methyl styrene, 0.5 parts of triethyl Amine, 1.5 parts of sodium dodecylbenzene sulfonate, 1.0 parts of alkylphenol ethoxylates.

[0035] The above raw materials were added into deionized water, and emulsified in a four-neck flask for 20 minutes to prepare a pre-emulsion, which was set aside.

[0036] In a 500 mL four-neck flask equipped with a stirrer, a thermometer, a reflux condenser and a constant pressure dropping funnel, add 50 parts of the above-mentioned pre-emulsion.

[0037] While stirring, add 0.5 parts of sodium dodecylbenzenesulfonate and 0.5 parts of alkylphenol polyoxyethylene ether, and raise the temperature to 80°C.

[0038] Add 10 parts of solution A and react for 20 minutes. The solution A contains sodium bicarbonate with a mass concentration of 3% and potass...

Embodiment 2

[0043] Accurately weigh the following raw materials by weight: 100 parts of E-51 epoxy resin, 10 parts of methacrylic acid, 10 parts of hydroxyethyl methacrylate, 20 parts of butyl acrylate, 10 parts of styrene, 0.5 parts of APM-95, 1.5 parts of sodium dodecylbenzenesulfonate, 1.0 parts of fatty alcohol polyoxyethylene ether.

[0044] The above raw materials were added into deionized water, and emulsified in a four-neck flask for 18 minutes to prepare a pre-emulsion, which was set aside.

[0045] In a 500 mL four-neck flask equipped with a stirrer, a thermometer, a reflux condenser and a constant pressure dropping funnel, add 30 parts of the above-mentioned pre-emulsion.

[0046] While stirring, add 0.5 part of sodium dodecylbenzenesulfonate, 0.5 part of fatty alcohol polyoxyethylene ether and 0.5 part of polyvinyl alcohol, and raise the temperature to 80°C.

[0047] Add 10 parts of solution A and react for 18 minutes. The solution A contains potassium persulfate with a mass co...

Embodiment 3

[0052] Accurately weigh the following raw materials by weight: 80 parts of E-44 epoxy resin, 5 parts of methacrylic acid, 5 parts of acrylic acid, 10 parts of hydroxypropyl methacrylate, 20 parts of butyl acrylate, 30 parts of styrene, 0.5 parts Ammonia water, 1.5 parts of sodium dodecylbenzene sulfonate, 1.0 parts of alkylphenol polyoxyethylene ether.

[0053] Add the above-mentioned raw materials into deionized water, and emulsify in a four-neck flask for 22 minutes to prepare a pre-emulsion for later use.

[0054] In a 500 mL four-neck flask equipped with a stirrer, a thermometer, a reflux condenser and a constant pressure dropping funnel, add 30 parts of the above-mentioned pre-emulsion.

[0055] While stirring, add 0.5 parts of sodium dodecylbenzenesulfonate and 0.5 parts of alkylphenol polyoxyethylene ether, and raise the temperature to 80°C.

[0056] Add 10 parts of solution A and react for 22 minutes. The solution A contains sodium bicarbonate with a mass concentratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com