MOP flame retardant, flame-retardant UV/moisture dually-cured conformal coating, and preparation method and application of flame-retardant UV/moisture dually-cured conformal coating

A dual-curing, flame retardant technology, applied in the direction of fire-resistant coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problem that flame-retardant UV moisture conformal coatings cannot take into account flame retardancy and stability, and achieve Excellent flame retardant effect, the effect of excellent flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

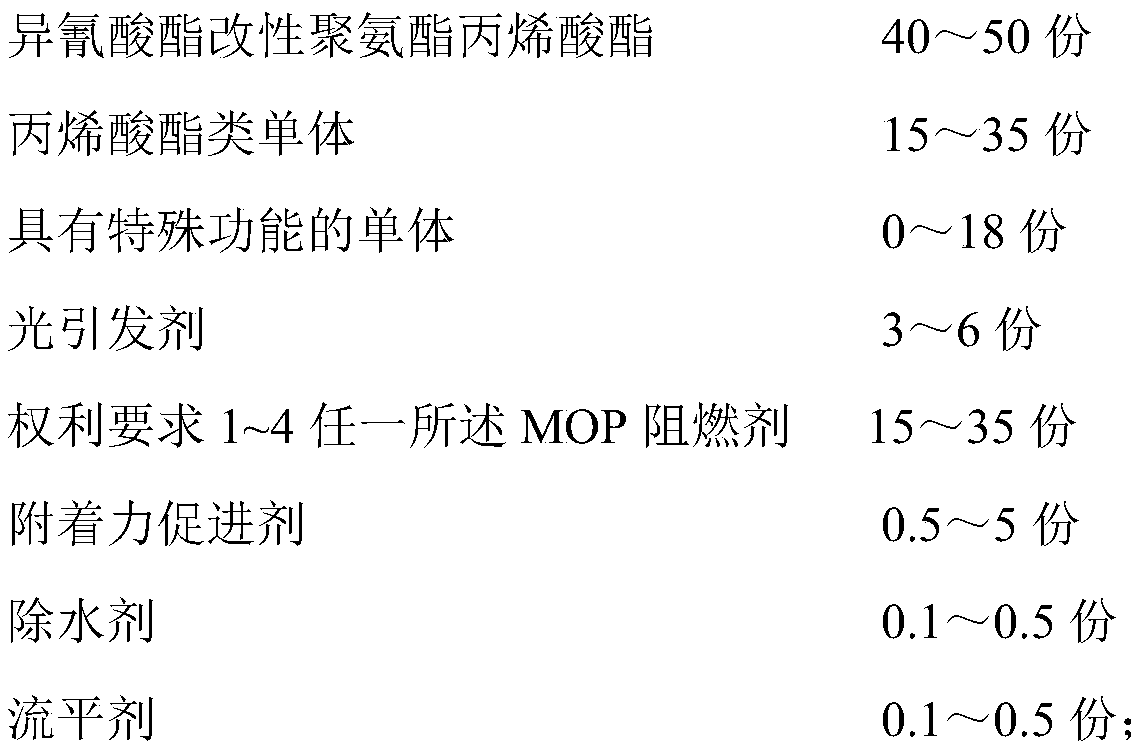

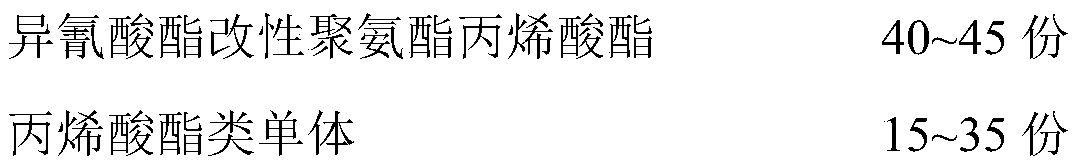

Method used

Image

Examples

Embodiment 1

[0052] This example provides a flame-retardant UV moisture dual-curing conformal paint, which consists of the following components: 40 parts of allnex 4150, 14 parts of isobornyl acrylate, 6 parts of diethyl acrylate, nine-dimensional 8 parts of 1203, 2 parts of photoinitiator W100, 2 parts of photoinitiator TPO, 1 part of photoinitiator 184, 15.2 parts of MOP flame retardant, 2 parts of Sartomer adhesion promoter CN-704, p-methylbenzenesulfonate Acyl isocyanate Additive TI 0.1 part, SC-403C 0.1 part.

[0053] The preparation process is as follows: sequentially add all raw materials except the initiator into a stirrer at a temperature of 20-30°C and a rotation speed of 300-800 rpm, stir for 0.5-1 hour and pass nitrogen protection until the stirring is uniform. Then add the photoinitiator to the stirrer, avoid light, control the temperature at 20-30°C, rotate at 300-800 rpm, protect with nitrogen, and finally seal it after defoaming under the vacuum of -0.1-0.05Mpa Fill and se...

Embodiment 2

[0055] This example provides a flame-retardant UV moisture dual-curing conformal paint, which consists of the following components: 40 parts of allnex 4150, 8 parts of isobornyl acrylate, 12 parts of diethyl ethyl phosphonate, nine-dimensional 8 parts of 1203, 2 parts of photoinitiator W100, 2 parts of photoinitiator TPO, 1 part of photoinitiator 184, 24.8 parts of MOP flame retardant, 2 parts of Sartomer CN-704, p-toluenesulfonyl isocyanate Additive TI 0.1 part, SC-403C 0.1 part.

[0056] Its preparation process is consistent with embodiment 1.

Embodiment 3

[0058] This example provides a flame-retardant UV moisture dual-curing conformal paint, which consists of the following components: 40 parts of allnex 4150, 5 parts of isobornyl acrylate, 10 parts of diethyl ethyl phosphonate, nine-dimensional 8 parts of 1203, 2 parts of photoinitiator W100, 2 parts of photoinitiator TPO, 1 part of photoinitiator 184, 29.8 parts of MOP flame retardant, 2 parts of Sartomer CN-704, p-toluenesulfonyl isocyanate Additive TI0 .1 part, SC-403C 0.1 part.

[0059] Its preparation process is consistent with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com